Environment-friendly recycling device for chemicals in chemical tempering furnaces

A chemical tempering and recovery device technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of poor cooling efficiency and achieve the effects of short recovery time, high recovery efficiency and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

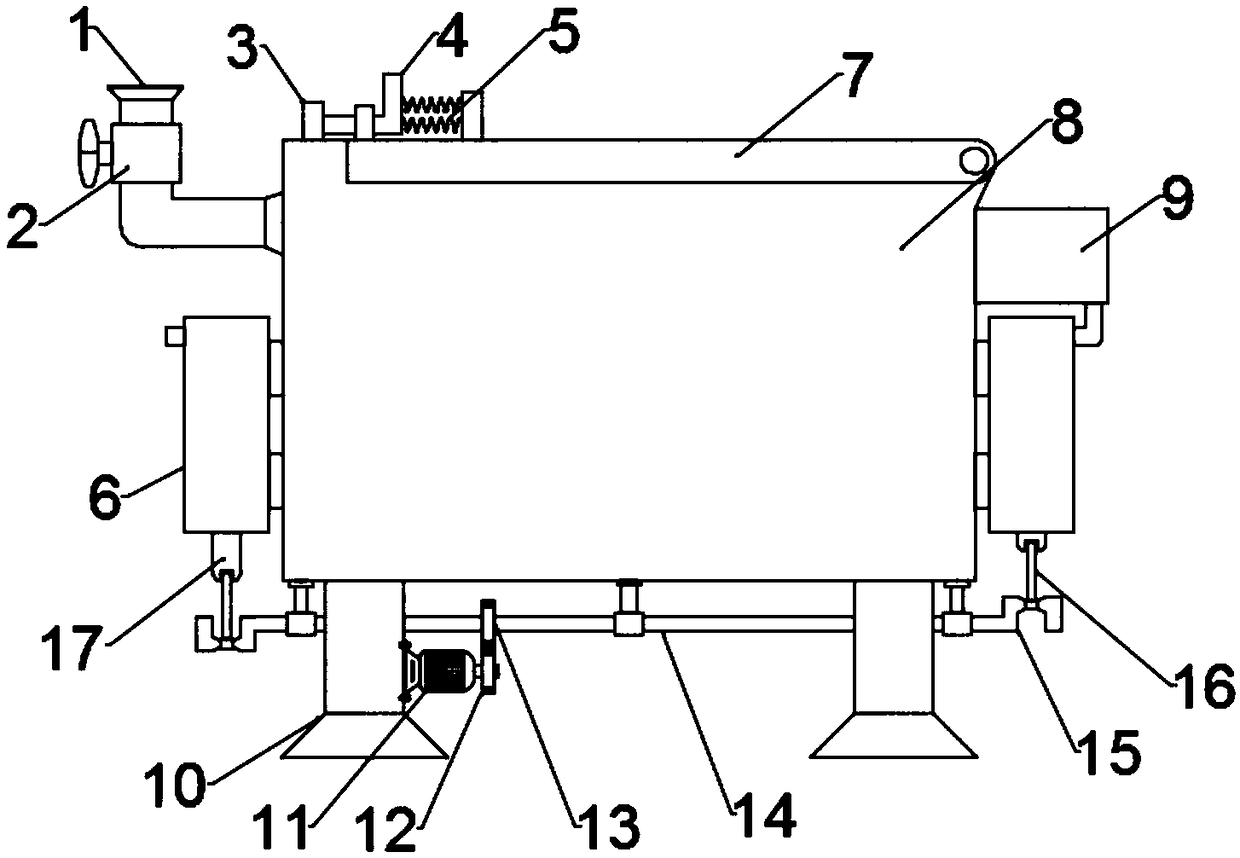

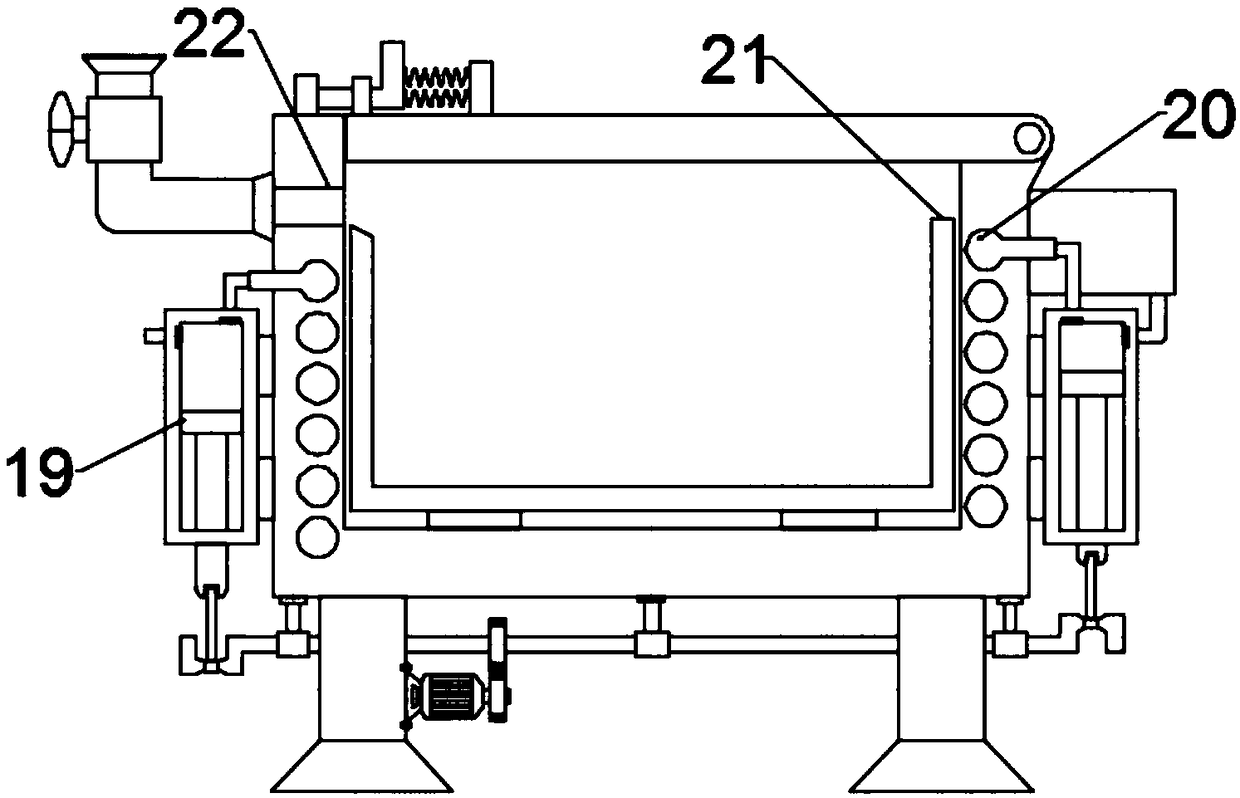

[0024] see figure 1 and 3 , an environment-friendly recovery device for chemicals in a chemical tempering furnace, comprising a recovery tank 8, a cooling mechanism and a liquid receiving tank 21; Slidingly connected, the recovery box 8 is provided with a cooling mechanism, the cooling mechanism includes a symmetrically arranged piston cylinder 6 and a cooling pipe 20, the cooling pipe 20 is wound on the inner wall of the recovery box 8, the air inlet of the cooling pipe 20 is connected to the The piston cylinder 6 on the right side is connected, and the air outlet of the cooling pipe 20 is connected with the piston cylinder 6 on the left side. A one-way valve is arranged on the inner side of the connection between the cold fire pipe 20 and the piston cylinder 6, and the inner side of the piston cylinder 6 is provided with There is a piston 19, the lower end of the piston 19 is fixedly connected with the upper end of the push rod 17, the lower end of the push rod 17 runs thro...

Embodiment 2

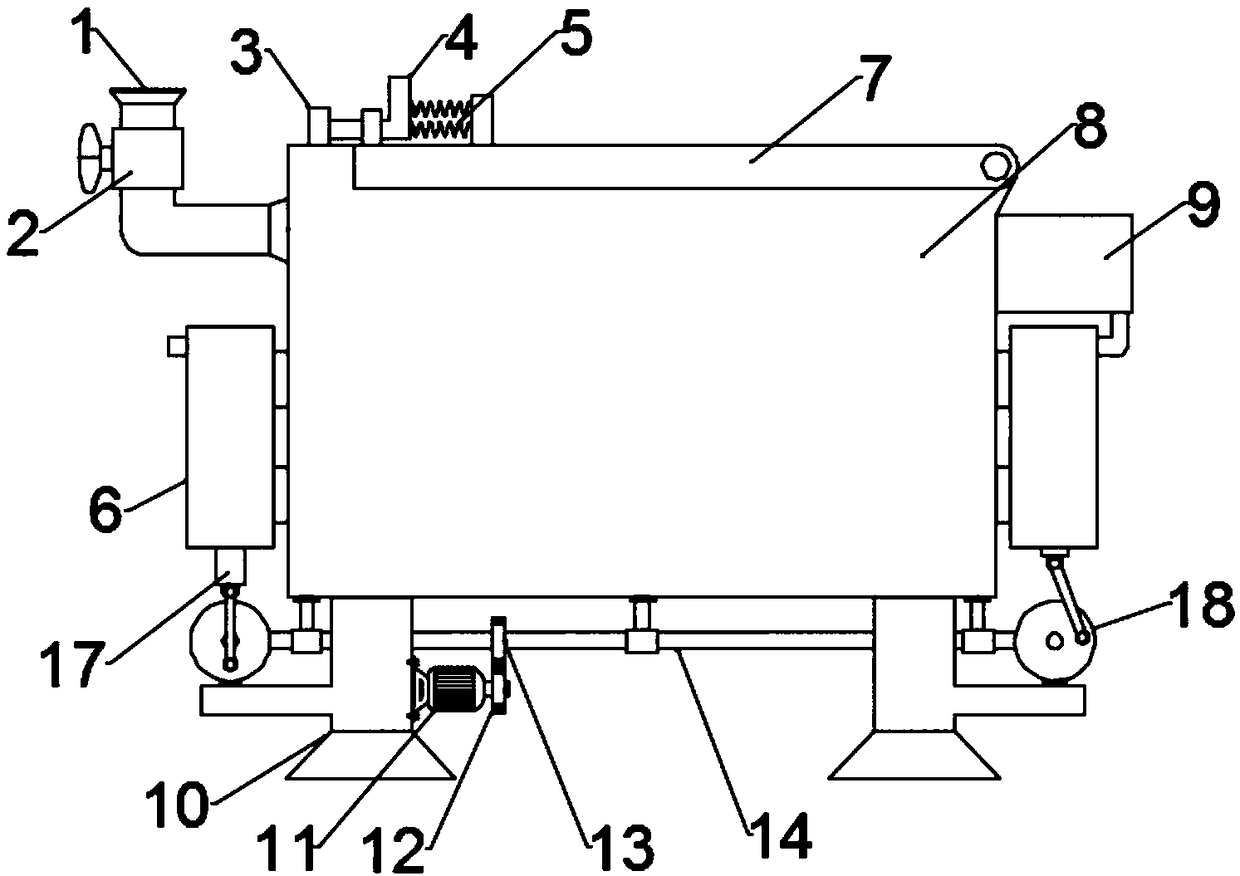

[0030] see figure 2 and 4 , an environment-friendly recovery device for chemicals in a chemical tempering furnace, comprising a recovery tank 8, a cooling mechanism and a liquid receiving tank 21; Slidingly connected, the recovery box 8 is provided with a cooling mechanism, the cooling mechanism includes a symmetrically arranged piston cylinder 6 and a cooling pipe 20, the cooling pipe 20 is wound on the inner wall of the recovery box 8, the air inlet of the cooling pipe 20 is connected to the The piston cylinder 6 on the right side is connected, and the air outlet of the cooling pipe 20 is connected with the piston cylinder 6 on the left side. A one-way valve is arranged on the inner side of the connection between the cold fire pipe 20 and the piston cylinder 6, and the inner side of the piston cylinder 6 is provided with There is a piston 19, the lower end of the piston 19 is fixedly connected to the upper end of the push rod 17, the lower end of the push rod 17 runs throu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap