Transient grouting material

A grouting material, transient technology, applied in the field of building materials, can solve the problems of slow setting time, poor fluidity, uneconomical, etc., and achieve the effect of avoiding setting time and avoiding construction difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

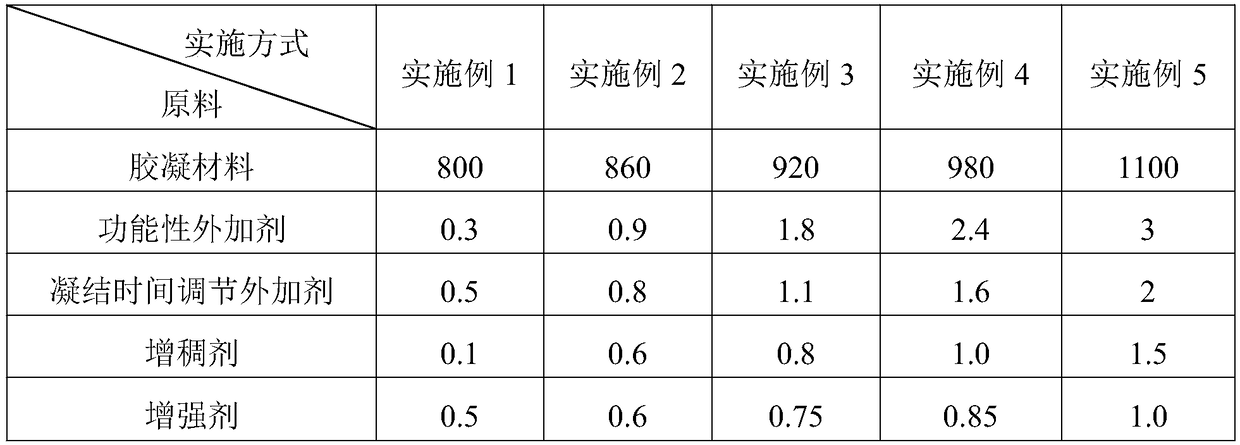

[0019] A transient grouting material, which consists of the following components in parts by mass:

[0020] 800-1100 parts of gelling material, 0.3-3 parts of functional admixture, 0.5-2 parts of setting time adjusting admixture, 0.1-1.5 parts of thickener, and 0.5-1 part of reinforcing agent.

[0021] The preferred cementitious material in the present invention is sulfur-aluminum cement.

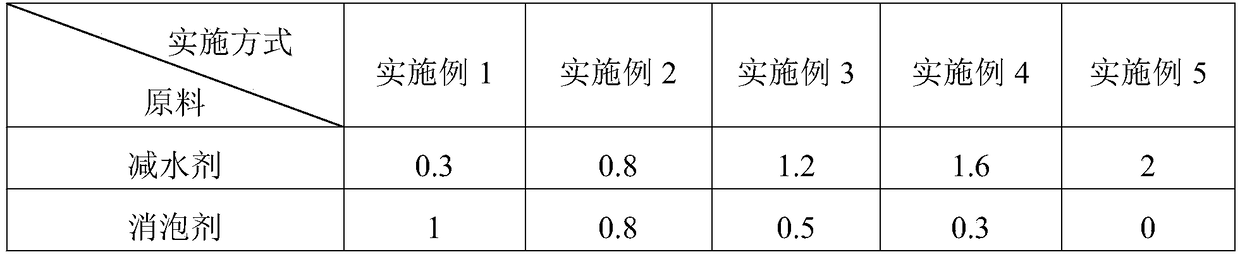

[0022] The composition of the preferred functional admixture in the present invention is as follows: 0.3-2 parts of water reducer and 0-1 part of defoamer. Use functional admixtures to control rheological properties and eliminate bubbles and other defects that will affect the performance of grouting materials.

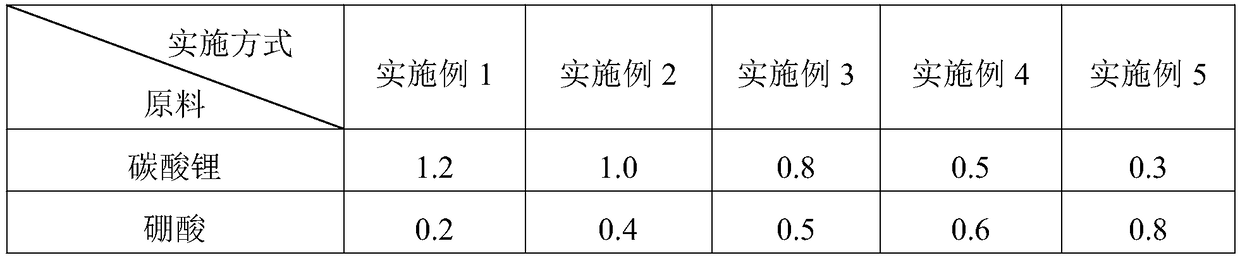

[0023] The mass parts composition of the preferred coagulation time regulating admixture of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com