Production device and dyeing technology of feather yarn

A technology for producing device and feather yarn, which is applied in piecing device, spinning machine, textile and papermaking, etc., can solve the problems of affecting the straightness of the core thread, yarn breakage, low efficiency, etc., to avoid hairiness and dislocation, and ensure the dyeing effect. , the effect of high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

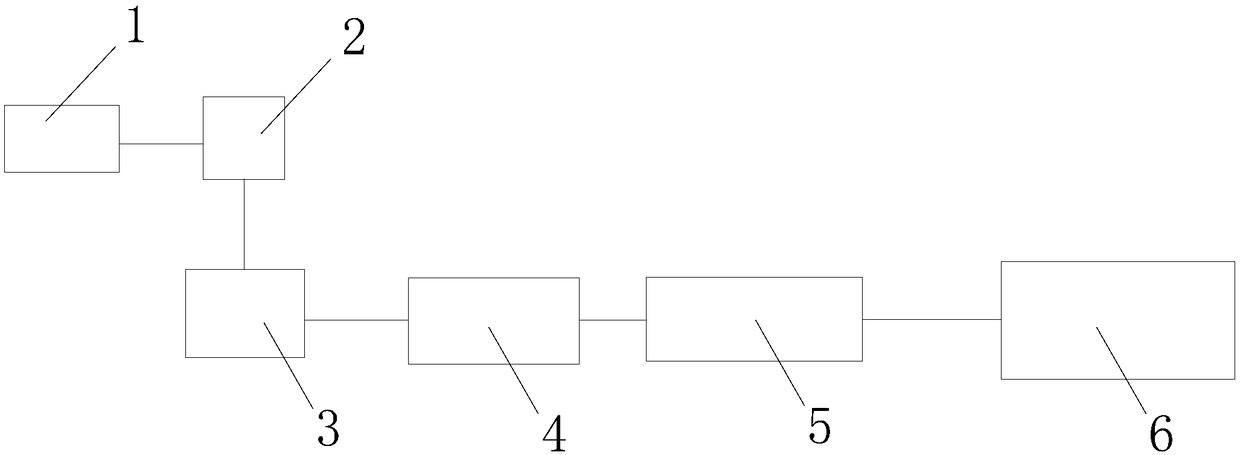

[0028] see Figure 1 to Figure 5 , the present invention relates to a production device for feather yarn and a dyeing process thereof, wherein the production device comprises a wool blending machine 1, a carding machine 2, a drawing frame 3, a roving frame 4, a spinning frame 5, and a dyeing vat 6, and the yarn raw material passes through the wool blending machine 1 After the wool is mixed, it is sent to the carding machine 2 for carding, so that the yarn raw material is loose and straight, and then sent to the drawing frame 3 to bundle into slivers to improve the uniformity of the yarn and reduce its unevenness, and then send it into the roving The yarn is made into roving in the machine 4, and then enters the spinning machine 5 to draft, twist and wind the semi-finished roving or sliver into a spun bobbin, and finally sends it to the dyeing vat 6 for dyeing treatment, and finally completes the feather yarn production.

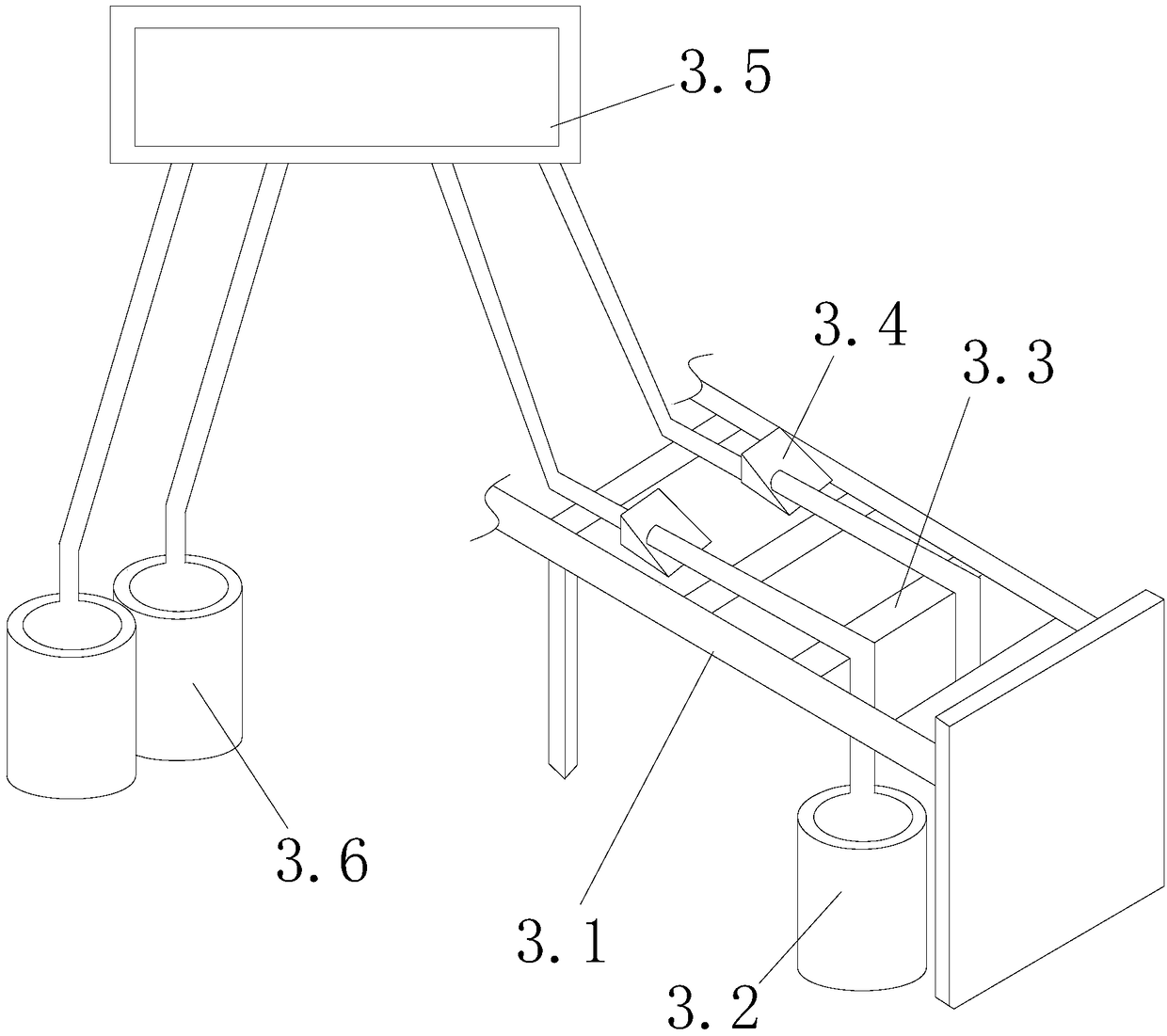

[0029] Wherein the drawing frame 3 comprises a frame 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com