Online replacement method for drying cylinder shaft head of paper mill

A replacement method and technology for paper mills, applied in papermaking, paper machines, textiles and papermaking, etc., can solve the problems of long replacement time, troublesome replacement of dryer shaft heads, etc., to achieve shortened downtime, elimination of collision risks, and convenient replacement. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

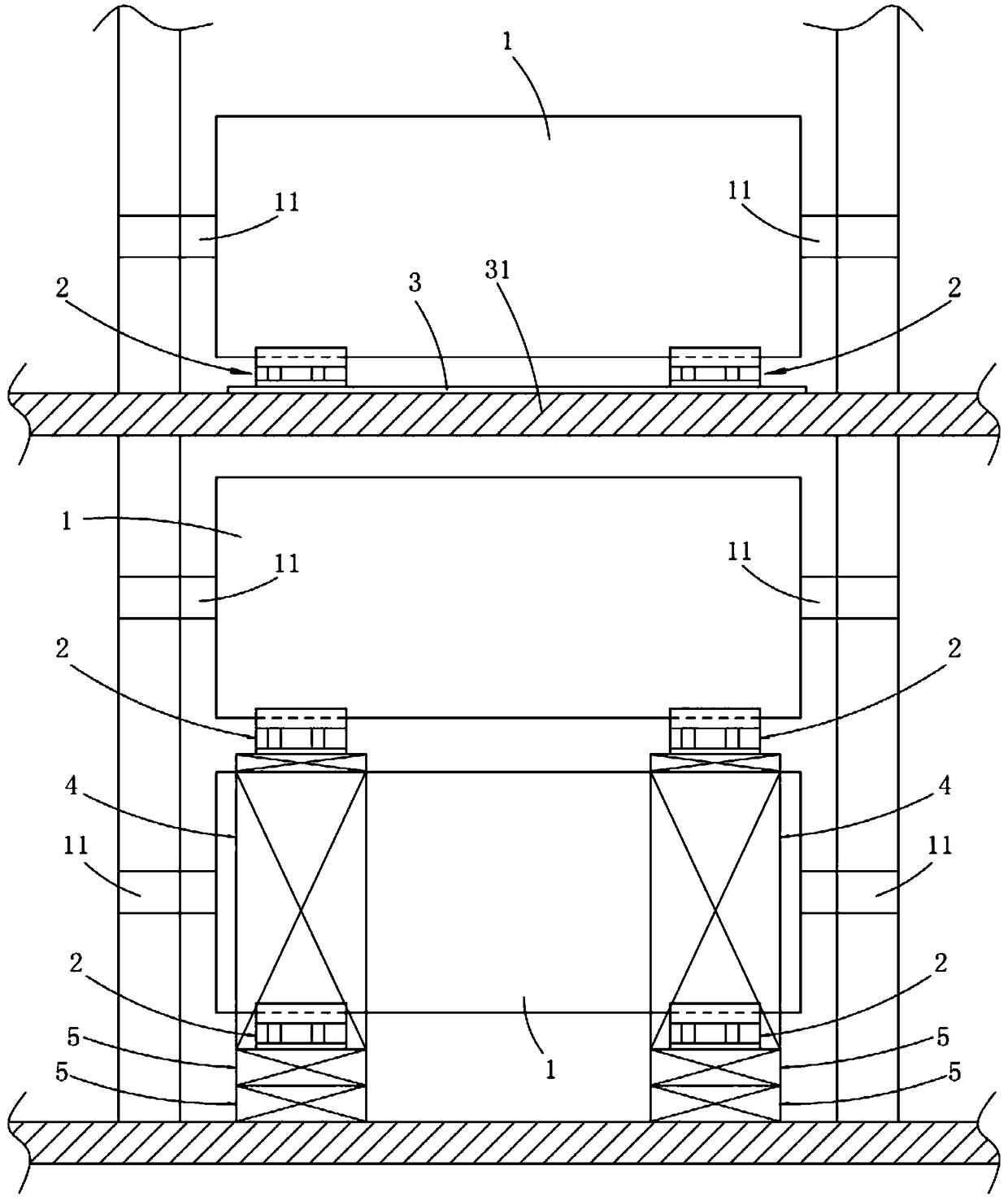

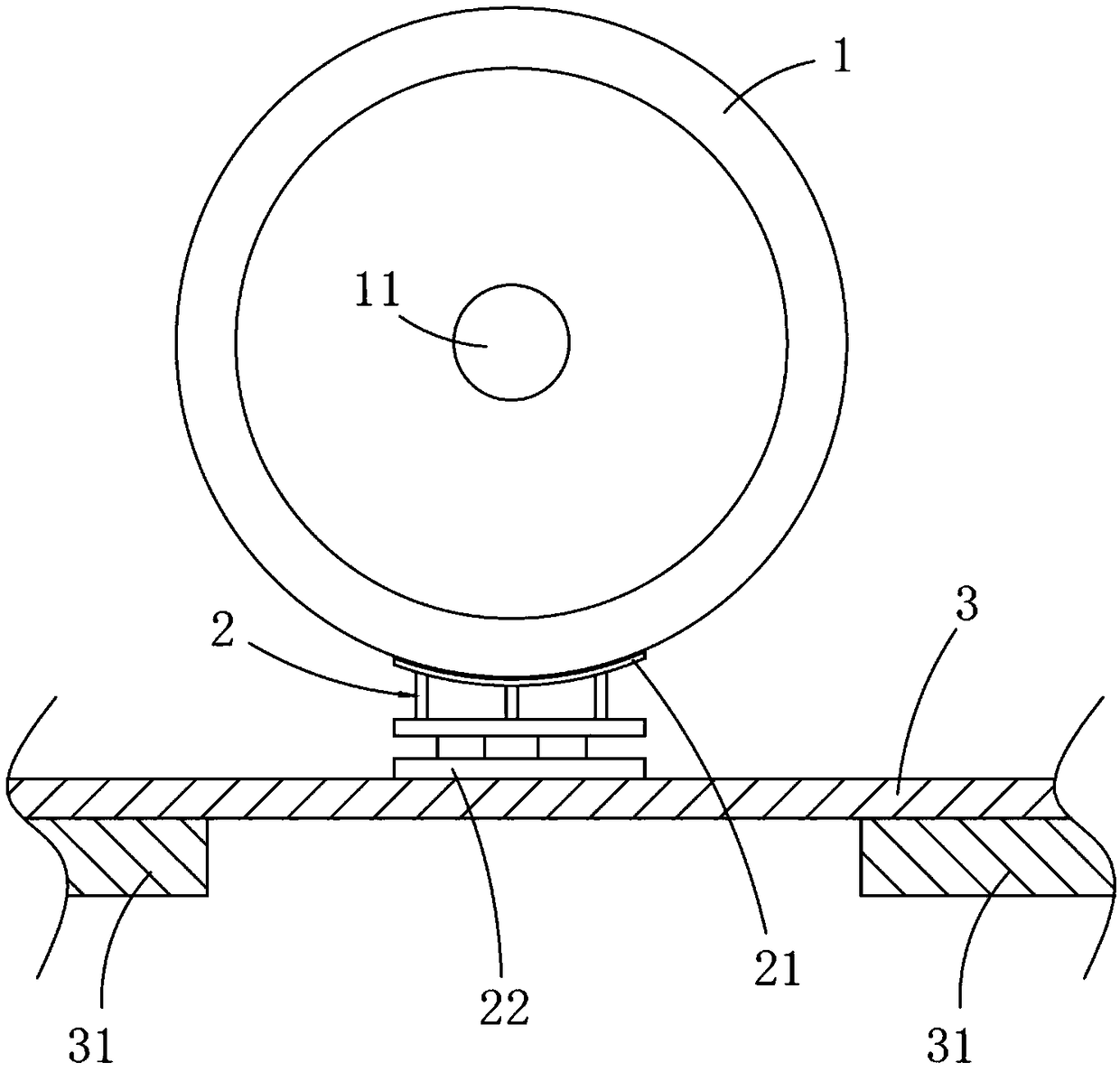

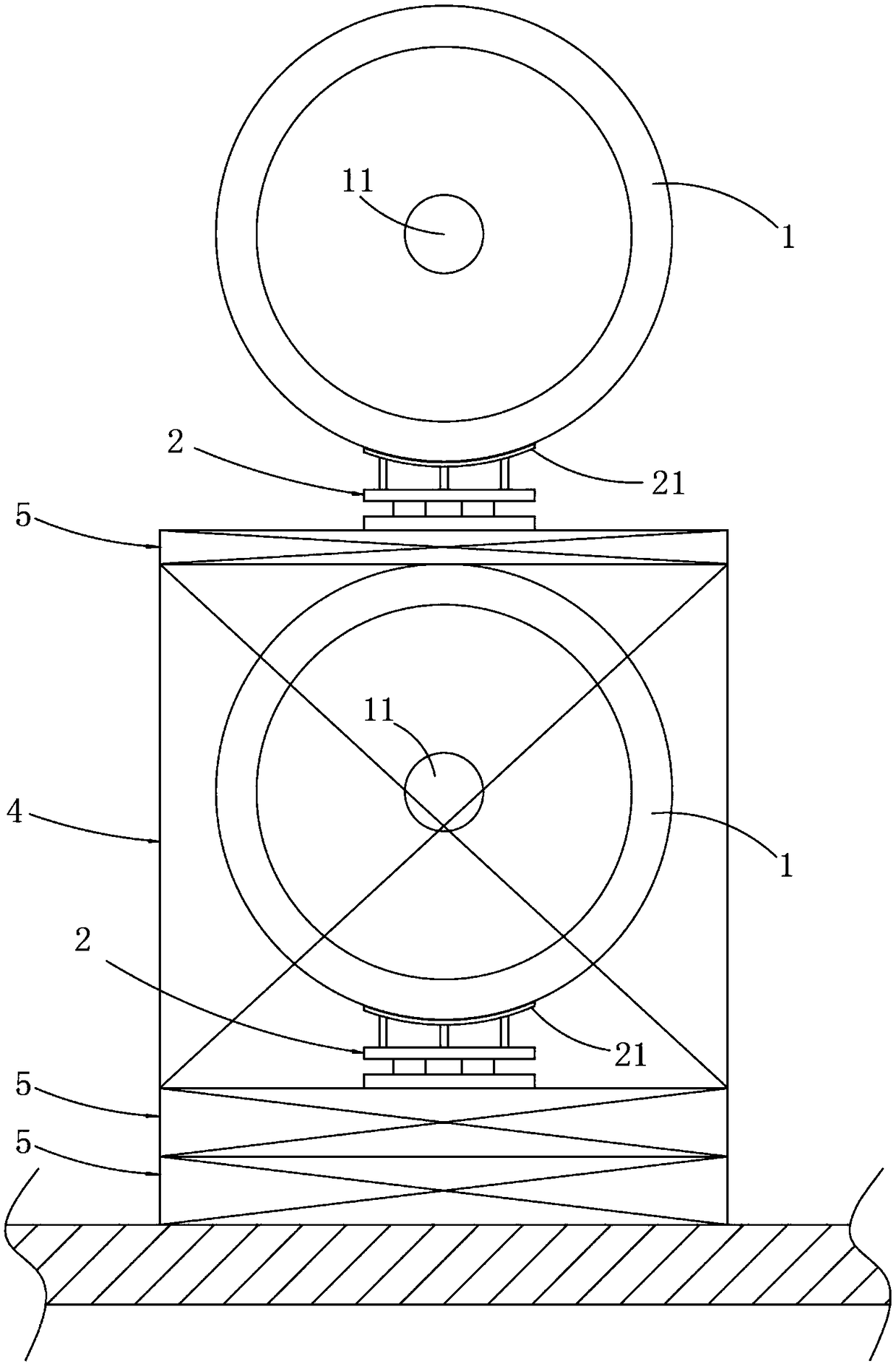

[0039] A method for online replacement of the shaft head of a drying cylinder in a paper mill, Figures 1 to 3 shown, including the following steps:

[0040]The online installation step of the lifting device 2 is to directly lift the drying cylinder 1 by a set distance in the production line through the lifting device 2. The lifting device 2 includes a base 22, a lifting group and an arc-shaped lifting plate 21. The lifting group is fixed on the base 22. The surface lifting plate 21 is fixed on the upper part of the lifting group. The top surface of the arc surface lifting plate 21 is an arc surface matching with the roller surface of the drying cylinder. Place a lifting device 2, and make the arc-shaped lifting plate 21 of the lifting device 2 close to the roller surface of the drying cylinder.

[0041] In the online insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com