Construction method of deepwater non-covering-layer steel trestle

A technology with no covering layer and construction method, which is applied in the direction of bridges, bridge materials, bridge construction, etc., can solve the problems of poor stability and easy overturning of steel trestle bridges without covering layers in deep water, so as to improve stability and anti-overturning performance, reduce The effect of flow resistance and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

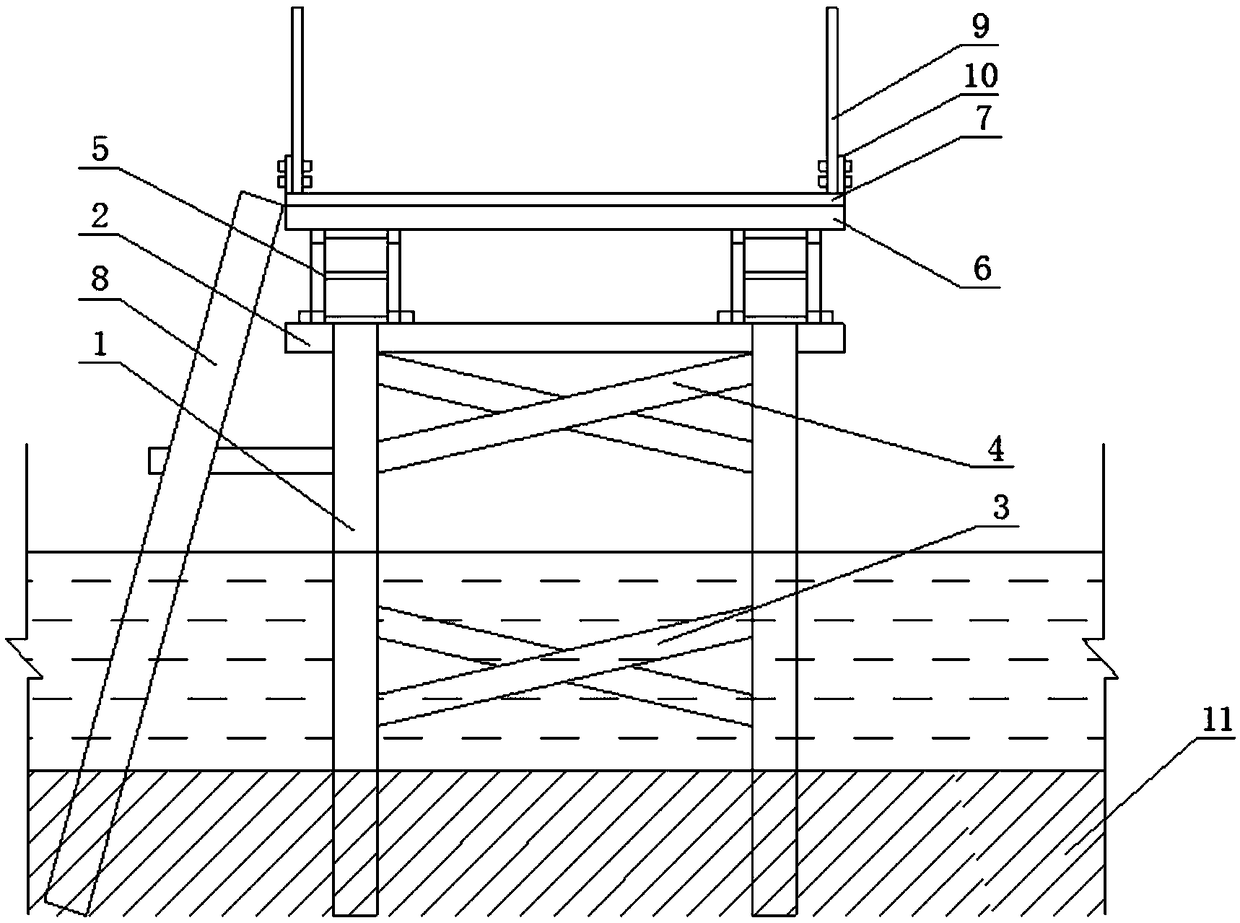

[0051] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

[0052] A construction method for a steel trestle bridge in deep water without covering, comprising the following steps:

[0053] (1) Steel pipe pile foundation construction: steel pipe piles 1 are installed on the riverbed 11 in the form of a single row of piles, and the pile top elevation is higher than the five-year flood level elevation. Great impact, the annual flood level data after the newly added water conservancy project should be provided by the hydrological station, comprehensively compare the construction cost and the stability factors of the steel trestle bridge; each steel pipe pile 1 is provided with a settlement observation point for monitoring. Describe the settlement situation of steel pipe pile 1; Wherein, the installation method of described steel pipe pile 1 comprises the following steps:

[0054] B1. Carry out rough position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com