Water permeable ground leveling machine

A technology for leveling machine and ground, applied in the direction of roads, road repair, roads, etc., can solve the problems of low construction accuracy, inability to control the density of permeable concrete mixes, internal gaps, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

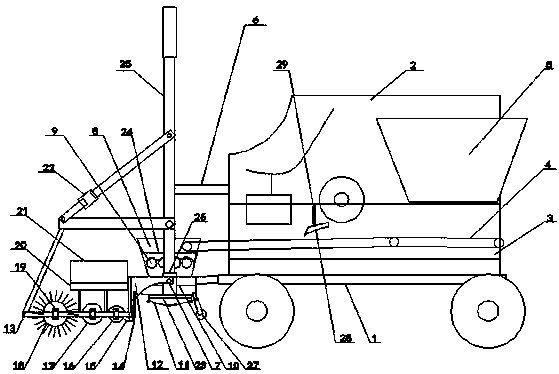

[0018] according to figure 1As shown, the present invention relates to a water-permeable ground leveling machine, which includes a tractor chassis 1 with road wheels, and the tractor chassis 1 is provided with a housing 2 with a V-shaped conveying channel 3, and the conveying channel A chute 29 is provided on the 3V-shaped side wall, and a hydraulic lifting plate 28 is installed in the chute 29, a power output device and a speed change device are installed in the housing 2, and a conveying device 4 is arranged in the conveying channel 3 A collection box 5 is installed at the rear end of the housing 2 and the discharge port of the collection box 5 corresponds to the rear end of the conveying device 4, and the front end of the tractor chassis 1 is provided with a suspension device 6, the Suspension device 6 is connected with a leveling working head 7, and described leveling working head 7 comprises material receiving box body 8, and the front end of described conveying device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com