Elastic oil sucker rod centralizer for oil fields

A technology for centralizers and sucker rods, which is applied in the direction of drill pipes, cleaning tools, drilling equipment, etc. It can solve the problems of reducing the service life of oil pipes, increasing maintenance costs, increasing the wear and tear of rollers and the inner wall of oil pipes, etc., so as to prolong the service life, Increased service life and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

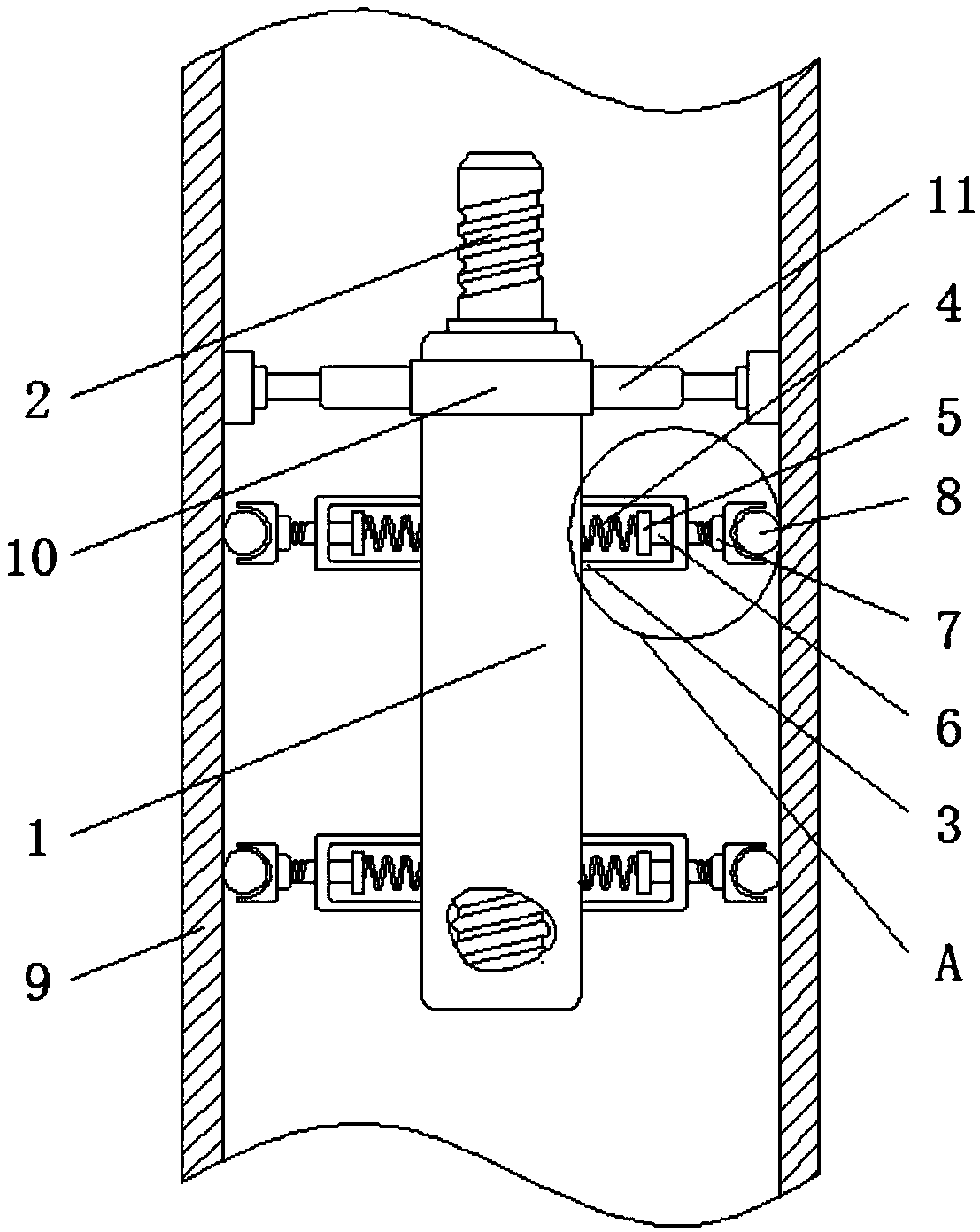

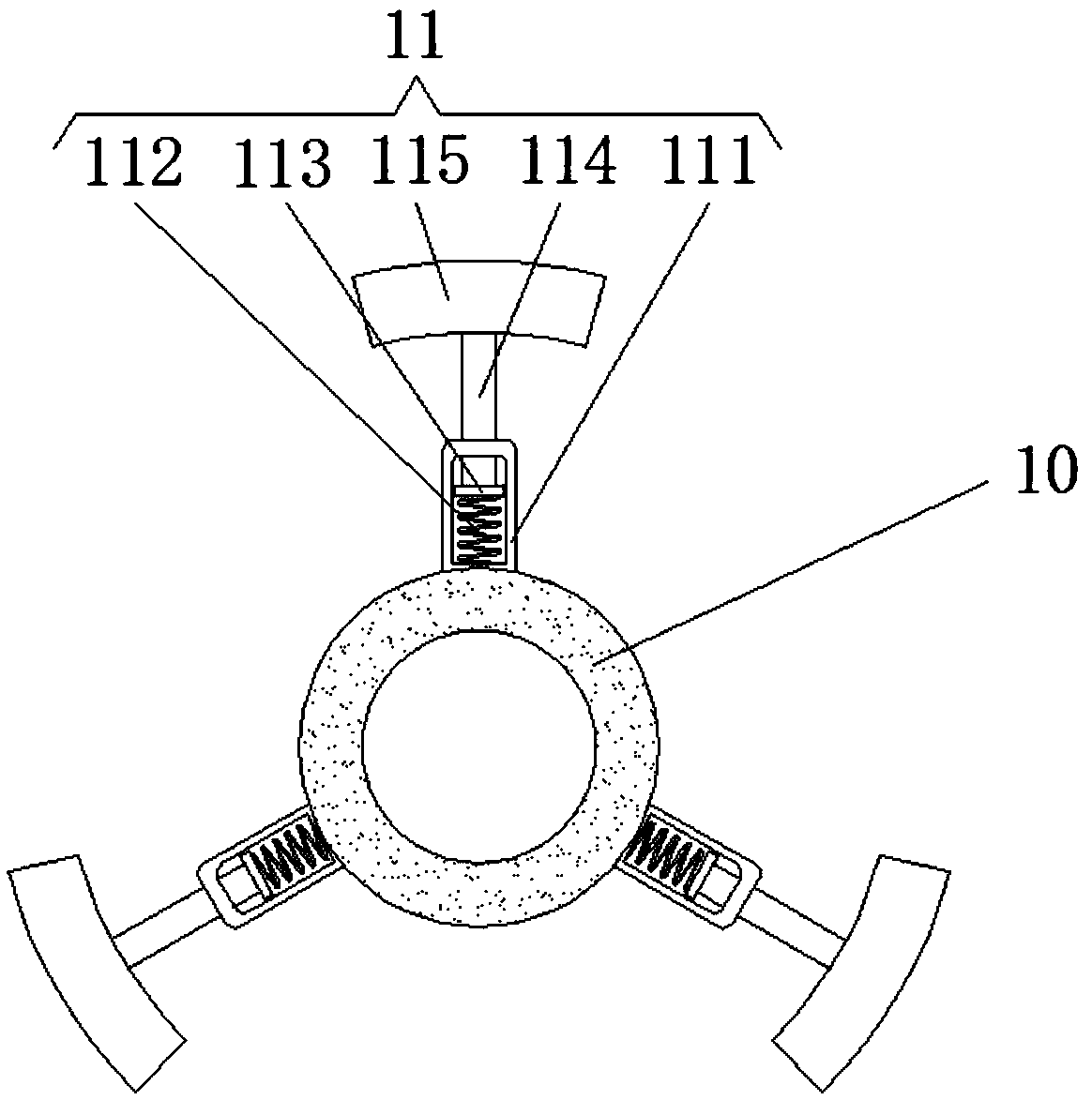

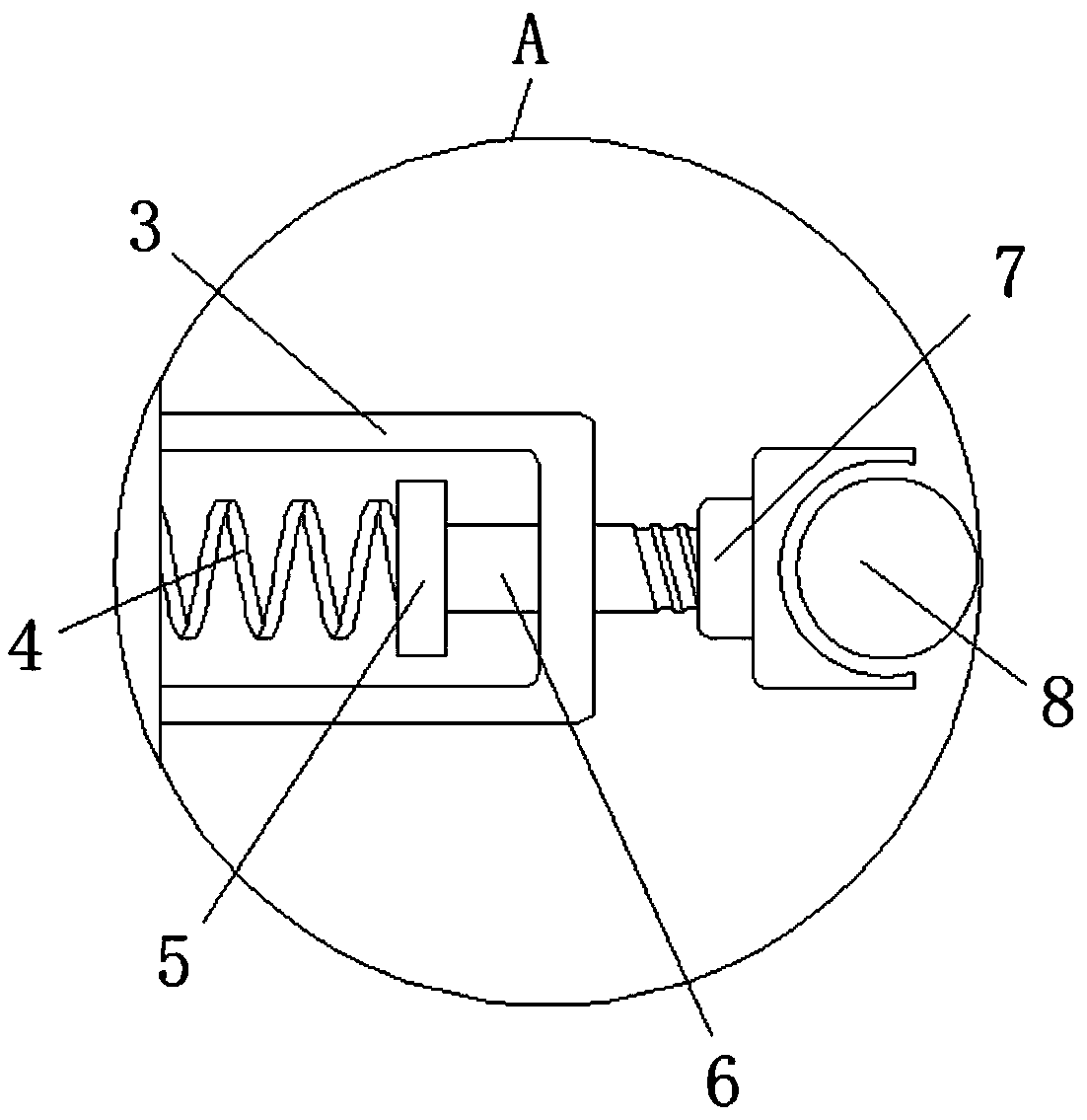

[0018] Below in conjunction with the accompanying drawings in the embodiment of the present invention, please refer to Figure 1-3 , an elastic sucker rod centralizer for oilfields, comprising a centralizer body 1, the top of the centralizer body 1 is fixedly connected to one end of a fixed screw 2, the bottom of the inner cavity of the centralizer body 1 is provided with an internal thread, and the inner thread The pitch is the same as that of the fixed screw 2. Through the setting of the internal thread, the centralizer can be quickly fixed on the sucker rod. It is firm when fixed and easy and convenient to disassemble, which improves the practicality of the elastic sucker rod centralizer used in the oil field. The top of one side of the centralizer body 1 is fixedly connected with one side of the adjustment sleeve 3, one side of the inner cavity of the adjustment sleeve 3 is fixedly connected with one end of the adjustment spring 4, and the other end of the adjustment spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com