A tunnel construction method including support structure

A support structure and tunnel construction technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as difficulty in assembling support structures, and achieve the effects of high rigidity, high precision, and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

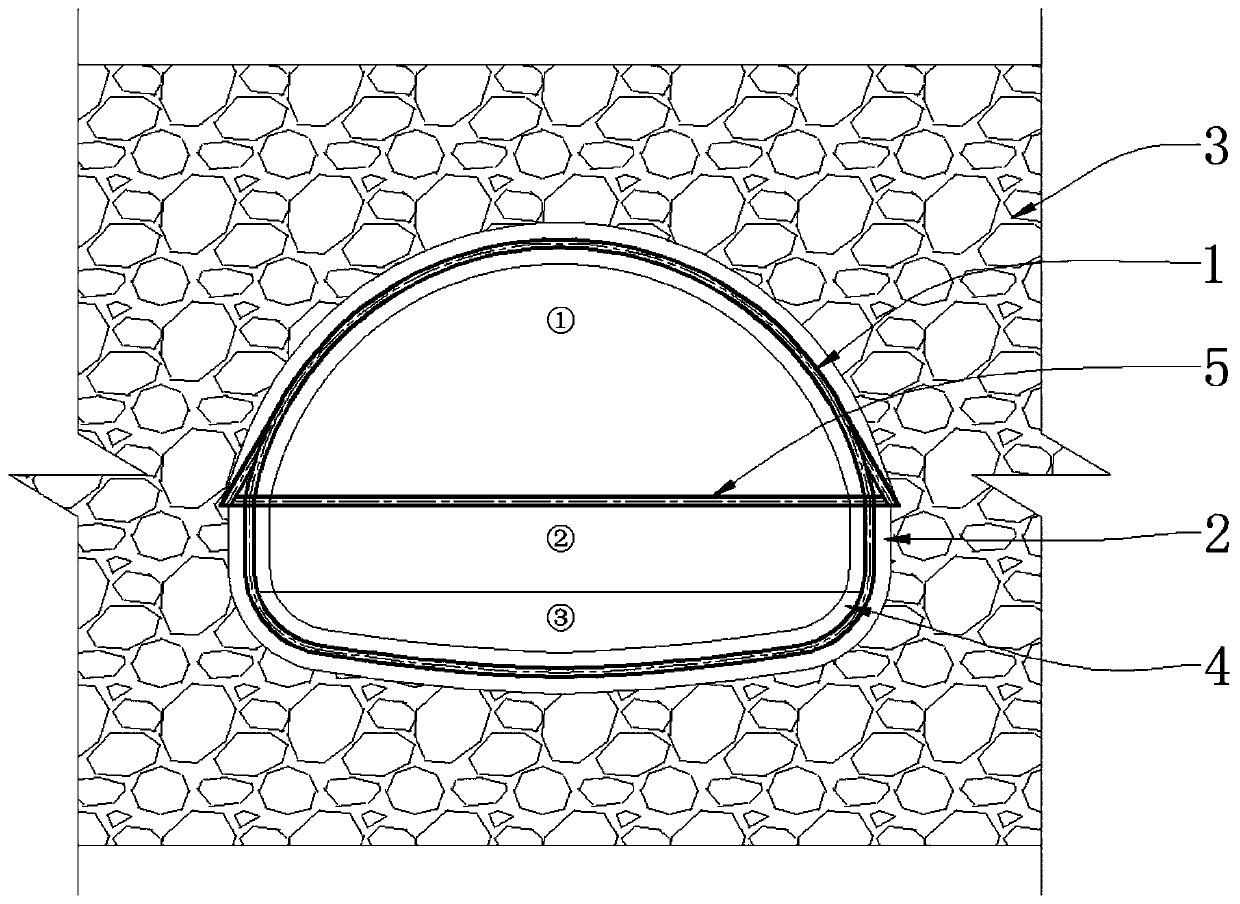

[0025] Take the step method tunnel construction as an example, such as figure 1 As shown, the specific construction steps are as follows:

[0026] (1) Determine the excavation process, subdivision size, and single longitudinal footage of the large-section tunnel: from top to bottom, it is divided into three subsections ①, ② and ③, and excavated in sequence;

[0027] (2) Excavate the specific subdivision ① to the design footage depth;

[0028] (3) Assemble the corrugated steel plate permanently from the side wall as the permanent support structure, and install trapezoidal rubber waterstop strips at the joints between the corrugated steel plates and fix them, and assemble the temporary support structure from the wall at the bottom of section ①; And place water bladders behind the temporary support structure;

[0029] (4) Tighten the bolts so that the design pre-tightening force is reached between the corrugated steel plates;

[0030] (5) Seal the end of the corrugated steel p...

Embodiment 2

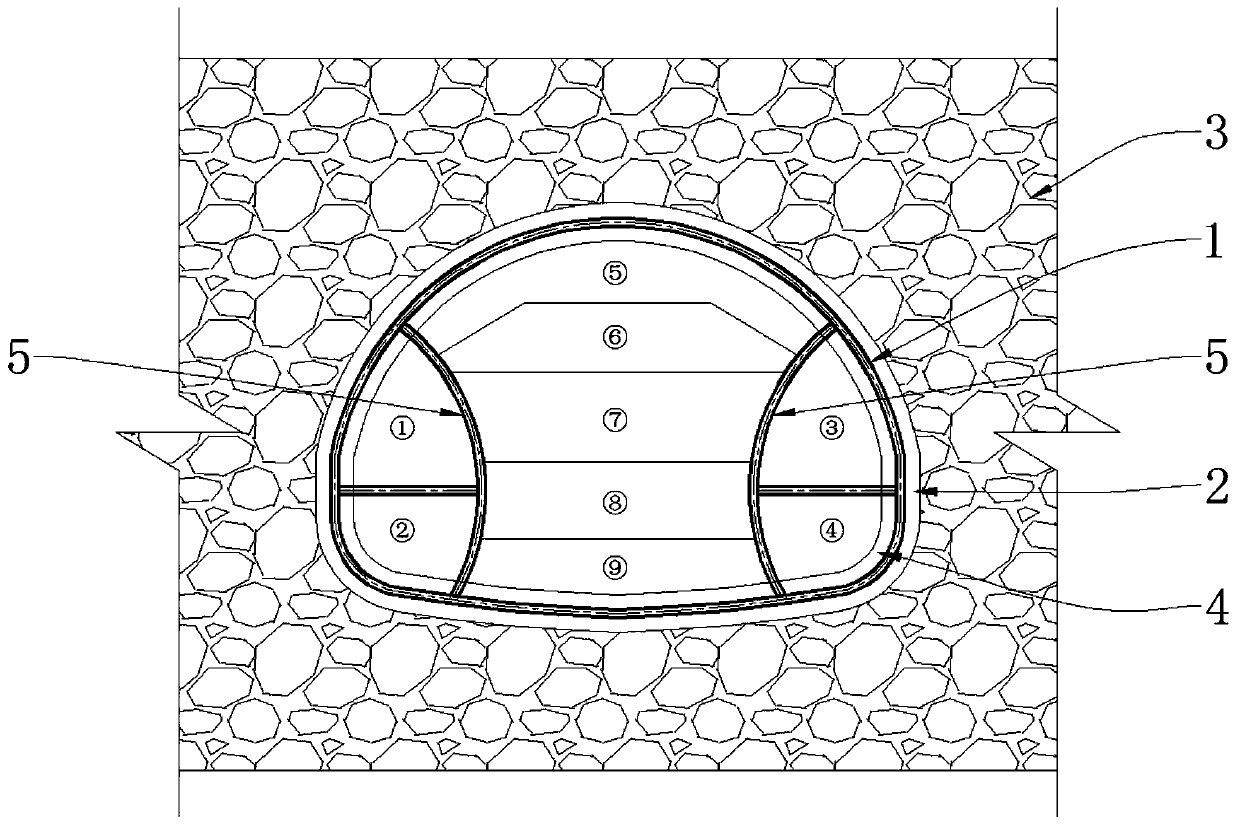

[0035] Taking the double-side-wall pilot-pit method tunnel construction as an example, such as figure 2 As shown, the specific construction steps are as follows:

[0036] (1) Determine the excavation process, subdivision size, and single longitudinal footage of the large-section tunnel: from top to bottom, it is divided into nine subdivisions ①, ②, ③, ④, ⑤, ⑥, ⑦, ⑧, and ⑨, and Excavation in sequence;

[0037] (2) Excavate the pilot pits of subsections ① and ② to the design footage depth;

[0038] (3) Assemble corrugated steel plates on the permanent side walls on the left side of subsections ① and ② as a permanent support structure. At the same time, install trapezoidal rubber waterstop strips at the joints between corrugated steel plates and fix them. ② Assemble the temporary support structure from the temporary side wall on the right side; place a water bag behind the temporary support structure; tighten the bolts to make the corrugated steel plate reach the design pre-ti...

Embodiment 3

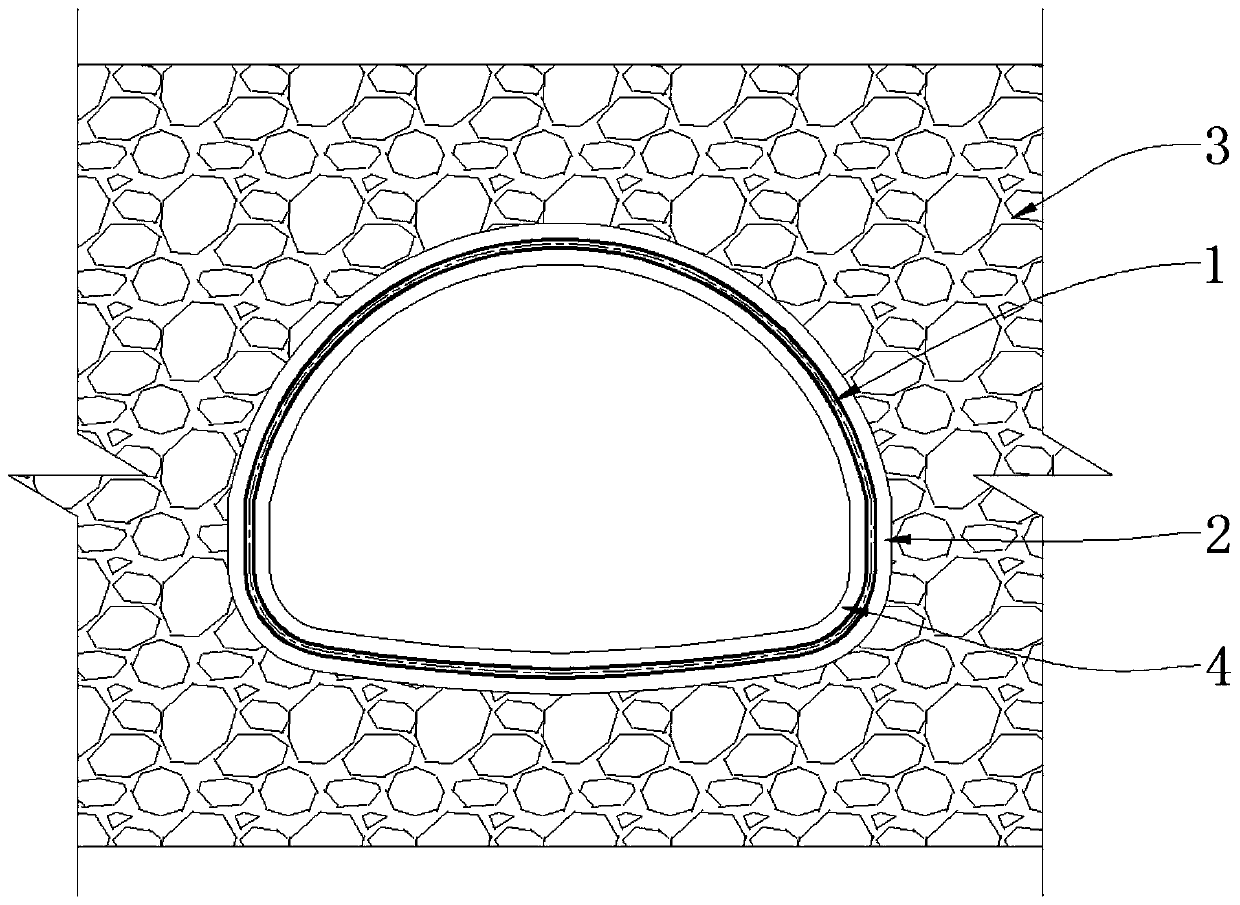

[0045] Such as image 3 Shown: For the full-section tunnel construction method, after a section of tunnel excavation, the integral permanent support structure can be assembled from the wall for airtight treatment, and then grout is poured between the permanent support structure and the surrounding rock until the grout solidifies Afterwards, the secondary lining is applied, and then the next section of the tunnel is constructed in such a cycle until the entire tunnel is completed. The construction method of the full-section tunnel is relatively simpler and more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com