Oil filter with sectional type pre-filtering structure

A segmented oil filter technology, applied in the filter field, can solve problems such as the inability to guarantee the oil supply speed and quality, interruption of engine oil supply, and decrease in oil circulation flow rate, etc., to reduce pollutants from clogging the filter element The probability of increasing the service life and the effect of relieving work pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

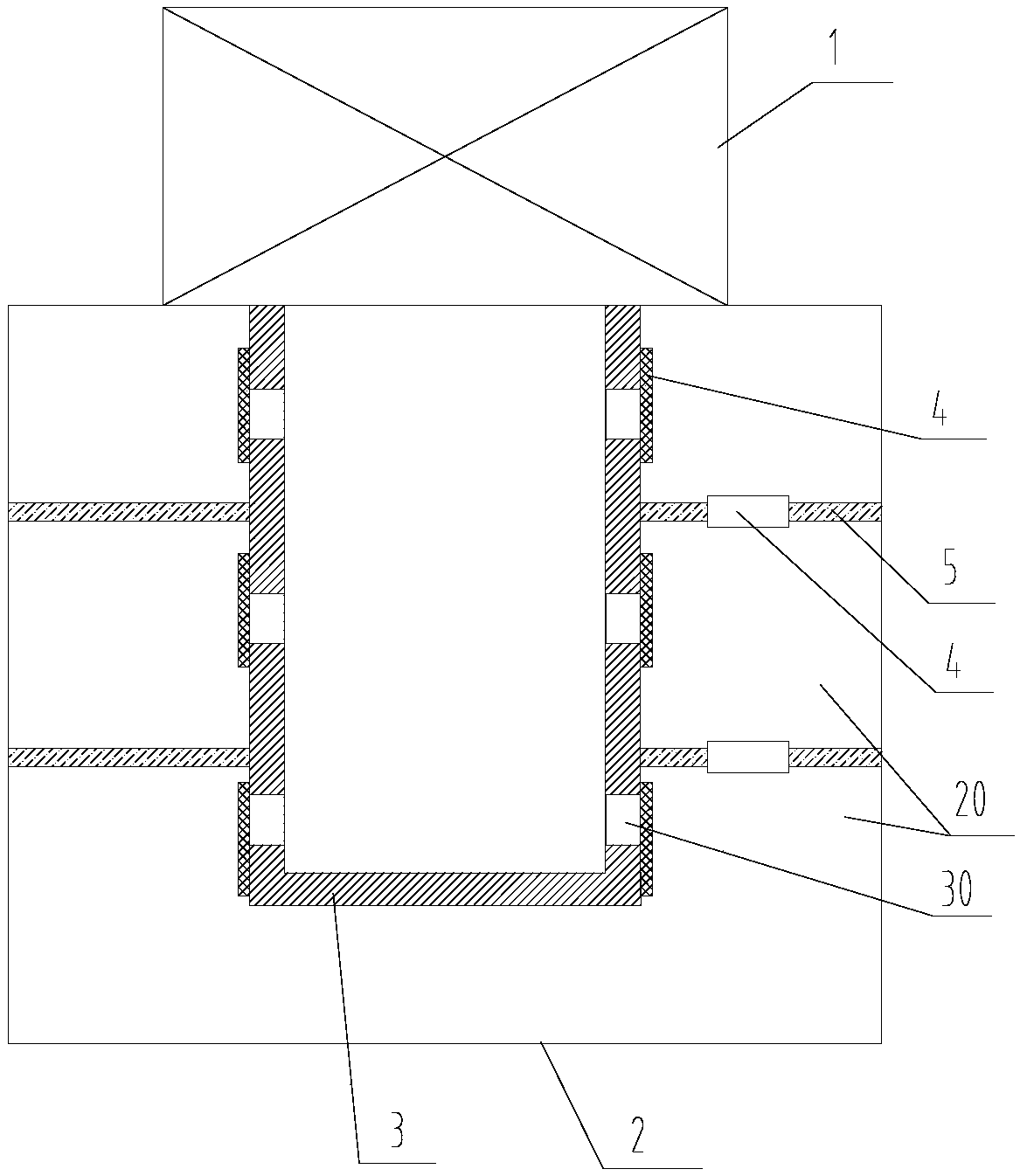

[0014] refer to figure 1 , the present invention proposes an oil filter with a segmented pre-filter structure, comprising: a filter element 1 , an outer cylinder 2 and an inner cylinder 3 .

[0015] One end of the inner cylinder 3 is unimpeded, and the other end is sealed. The outer cylinder 2 has a sealed structure at both ends. The inner cylinder 3 is installed inside the outer cylinder 2, and the filter element 1 is installed on the outer cylinder 2. The inlet of the filter element 1 is sealed and communicated with the unblocked end of the inner cylinder 3, so that the oil to be filtered in the inner cylinder 3 can overflow into the filter element 1 to filter. A plurality of through-hole units 30 connecting the inner and outer sides of the inner cylinder 3 are sequentially arranged in the axial direction, and the outer circumference of each through-hole unit 30 is covered with a filter membrane 4, so that the oil to be filtered in the outer cylinder 2 can pass through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com