Adjustable convergence and diffusion tail spraying pipe

A diffusive, tail nozzle technology, applied in jet propulsion devices, machines/engines, etc., can solve the problems of large thrust loss, complex structure, heavy weight, etc., and achieve the effect of improving performance, simple structure principle, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

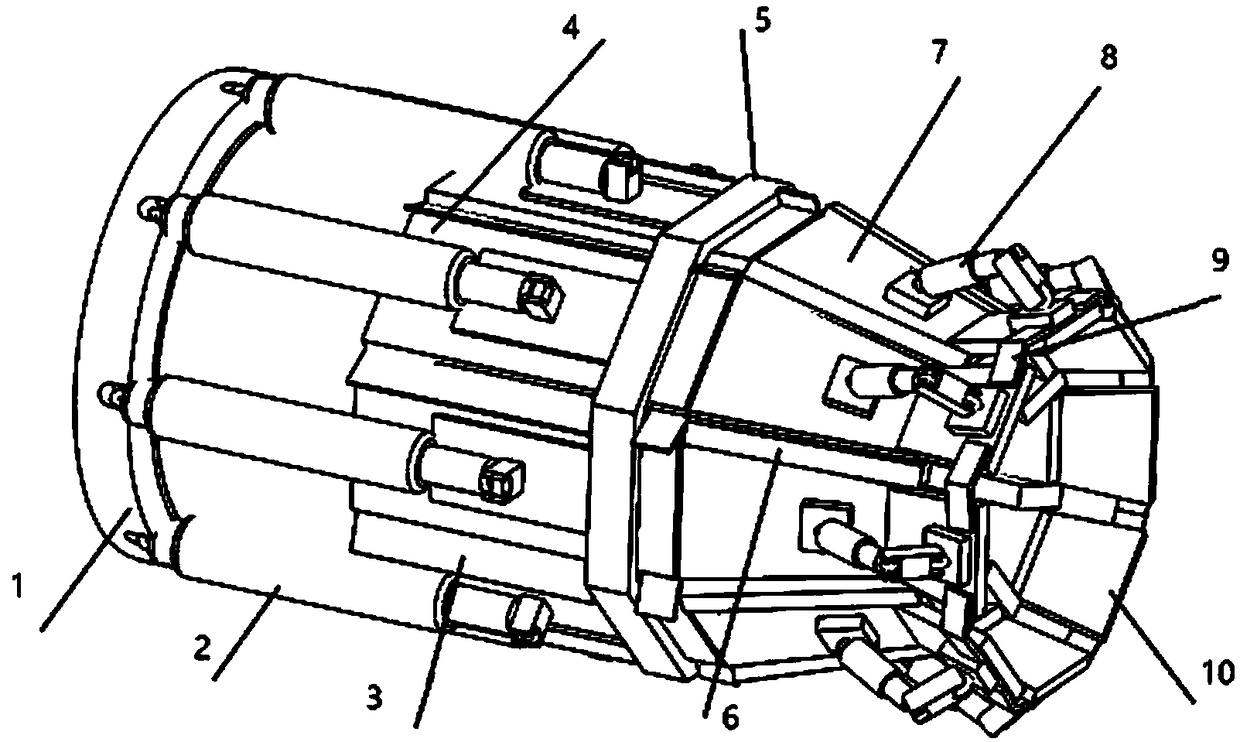

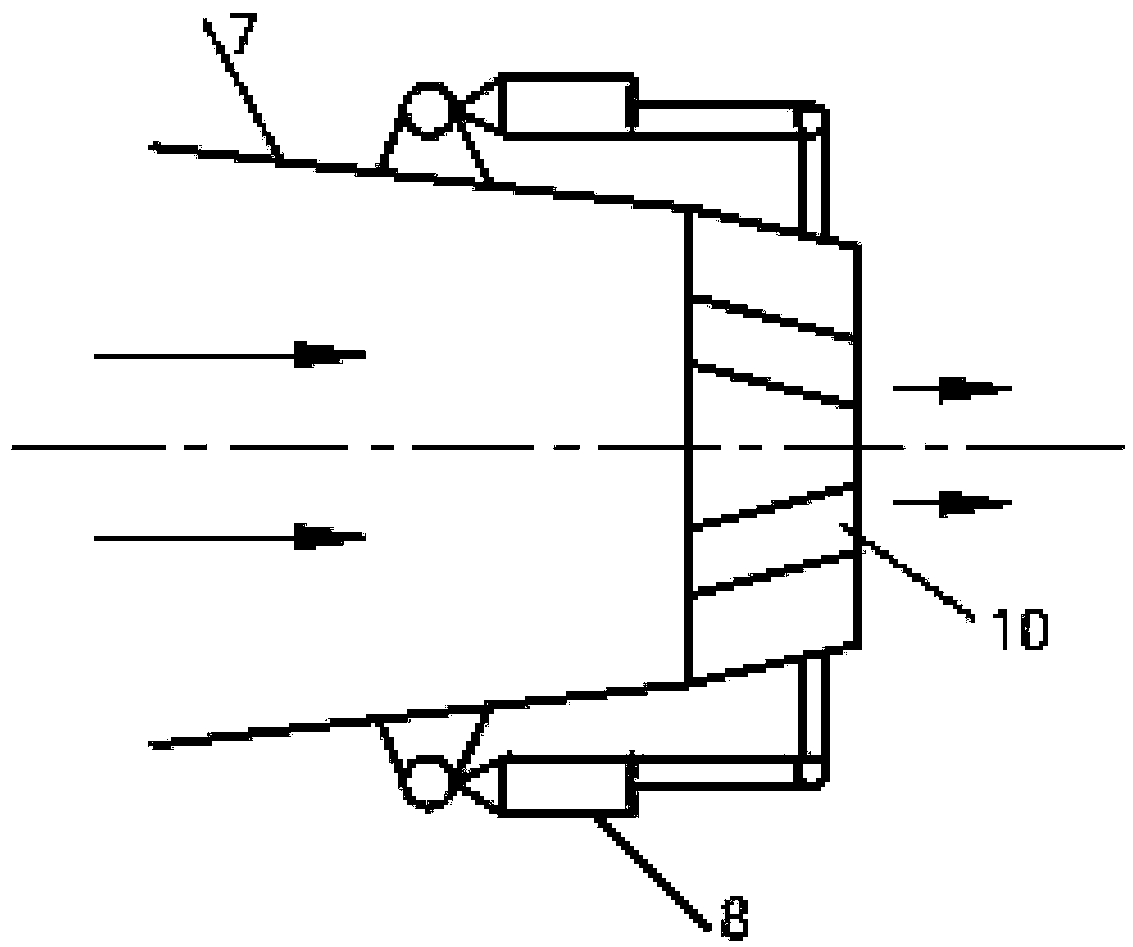

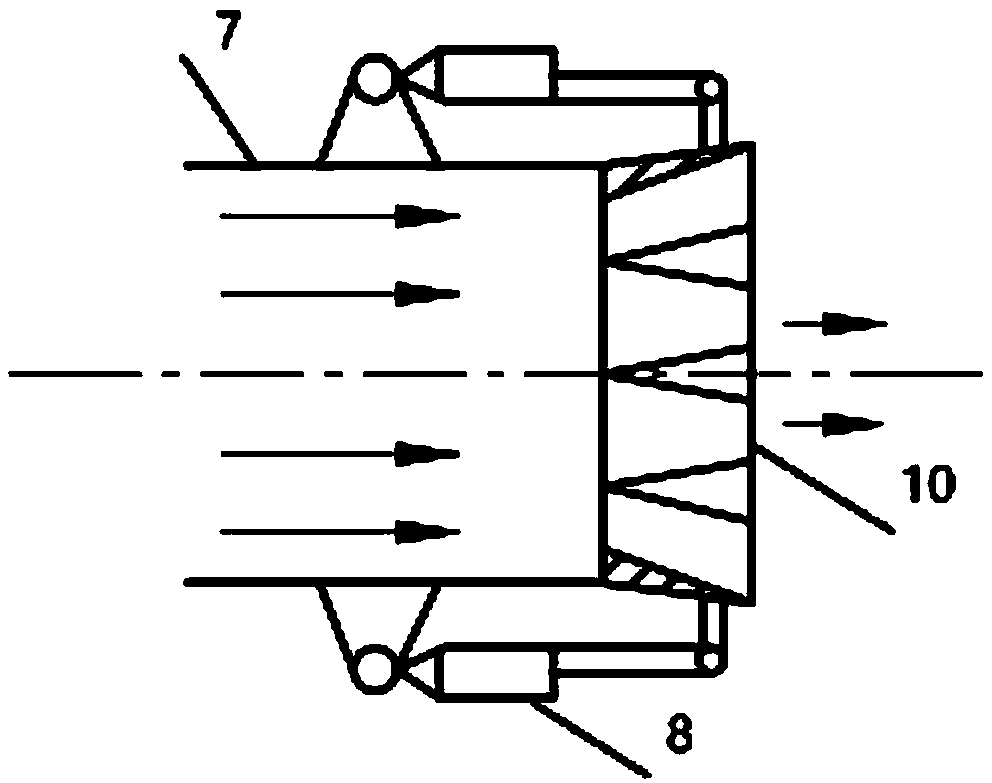

Embodiment Construction

[0015] see Figure 1-Figure 3 , The present invention provides the following technical solutions: an adjustable convergent-divergent tail nozzle, including a subsonic nozzle, a supersonic nozzle, and an elastic outer regulating piece. The subsonic nozzle consists of 16 regulating pieces and 16 sealing pieces. The adjusting sheets are alternately connected with the sealing sheets, and are fixed by additional fixing pieces. Each tab is hydraulically fixed to the hinged housing which is fixed to the rear mounting edge of the afterburner housing. The supersonic nozzle consists of 16 regulating plates and 16 sealing plates. 16 regulating pieces and 16 sealing pieces are arranged at intervals to form a diffuse supersonic nozzle. The front ends of the supersonic regulating plate and the sealing plate are respectively hinged with the subsonic regulating plate and the sealing plate. The elastic outer regulating piece is composed of 16 regulating pieces and 16 elastic pieces. A pne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com