Liquid-level monitoring system for ship fire-control high-pressure sealed fire extinguishing agent container

A technology for liquid level monitoring and fire extinguishing agent, which is used in liquid/fluid solid measurement, instruments, measuring devices, etc., can solve the problems of inability to carry out fire extinguishing normally, waste of fire extinguishing agent, insufficient fire extinguishing agent, etc. Fire safety, the effect of improving the level of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

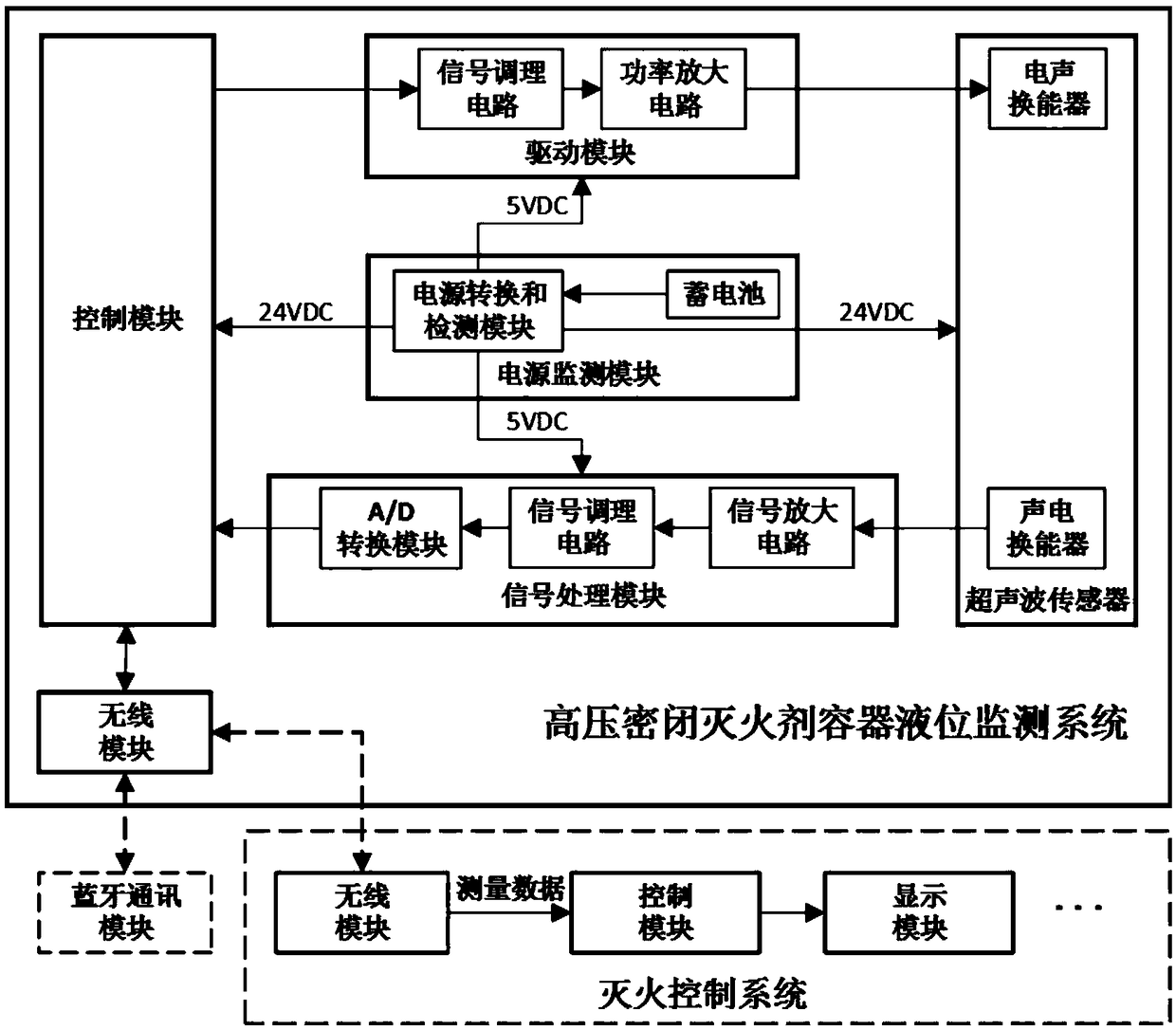

[0018] The invention includes a power monitoring module, a control module, a driving module, a signal processing module, an ultrasonic sensor and a wireless module. The power monitoring module is used to provide 24V and 5V DC voltage to the control module, drive module, signal processing module and ultrasonic sensor. The control module sends a control signal to the drive module, and the signal is converted into an electrical signal capable of driving the ultrasonic sensor after being processed by the drive module, and the sensor is driven to emit ultrasonic waves for liquid level measurement. After the echo signal is processed by the ultrasonic sensor, it is converted into an electrical signal again, and the electrical signal is output by the ultrasonic sensor to the signal processing module for identification and processing. The measurement data signal output by the signal processing module is received by the control module, and the control module calculates the measured liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com