Diagnostic method of aero-engine rotor fault

An aero-engine and diagnostic method technology, which is applied in the testing of engines, testing of machine/structural components, measuring devices, etc., can solve the problem of single diagnostic method, reasonable extraction of rotor fault features, and inability to effectively filter noise background spectrum. To achieve the effect of easier determination of clustering parameters, removal of noise interference, and convenient selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0066] An implementation case of a diagnosis method for an aeroengine rotor fault, including the following process:

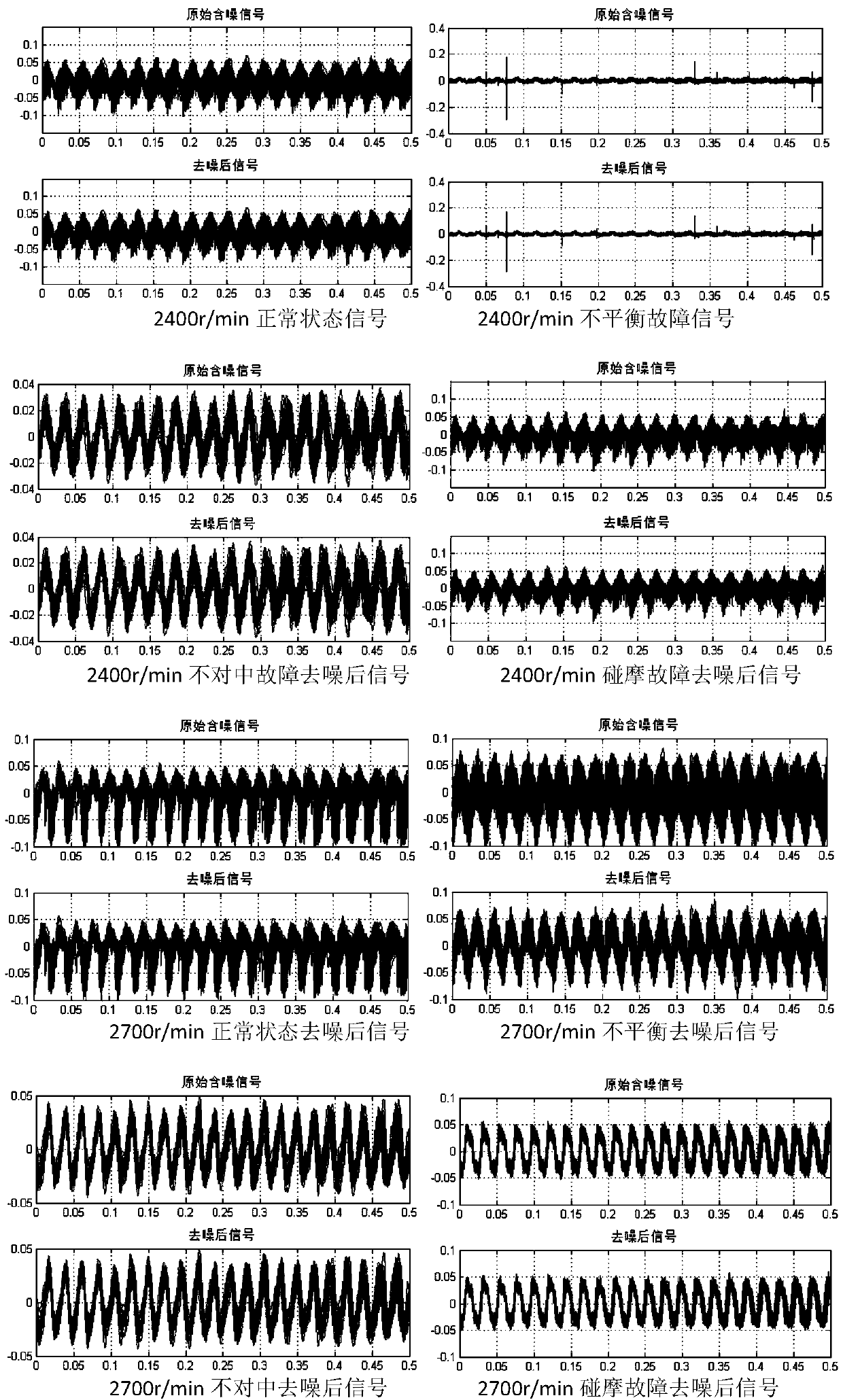

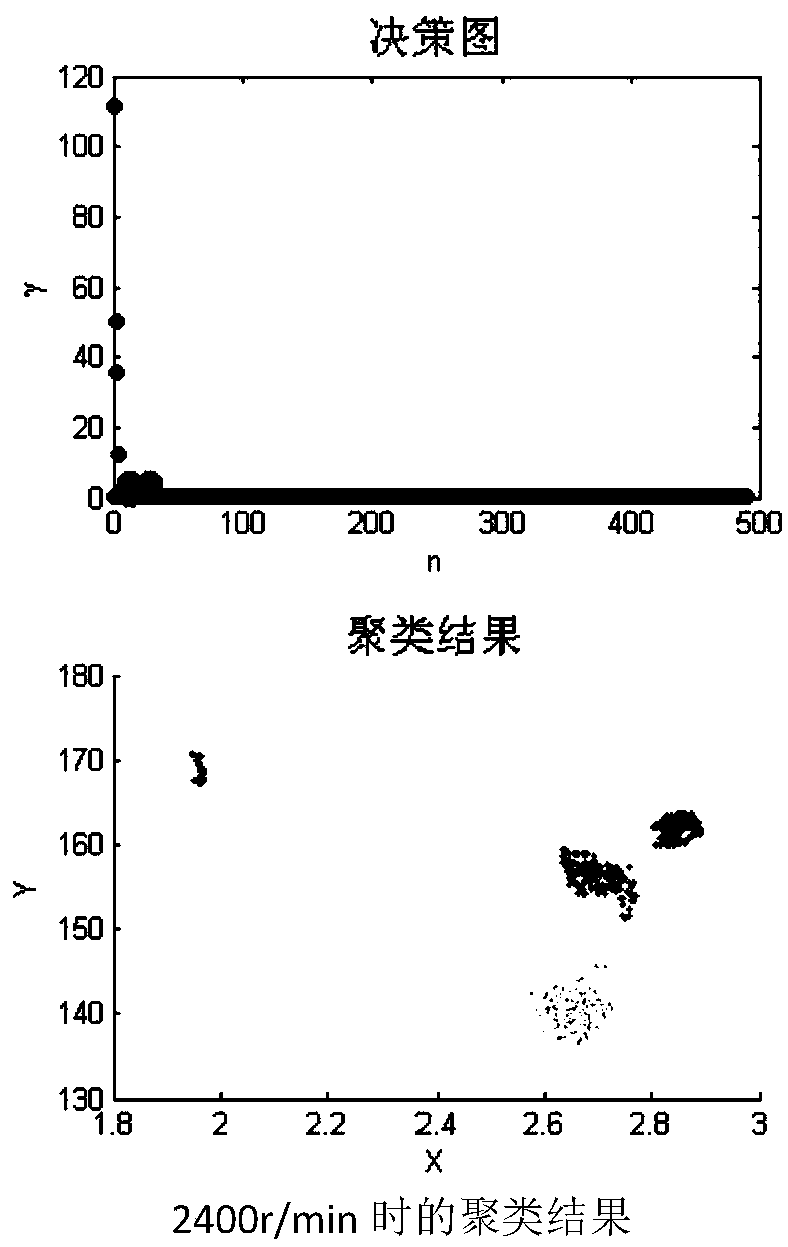

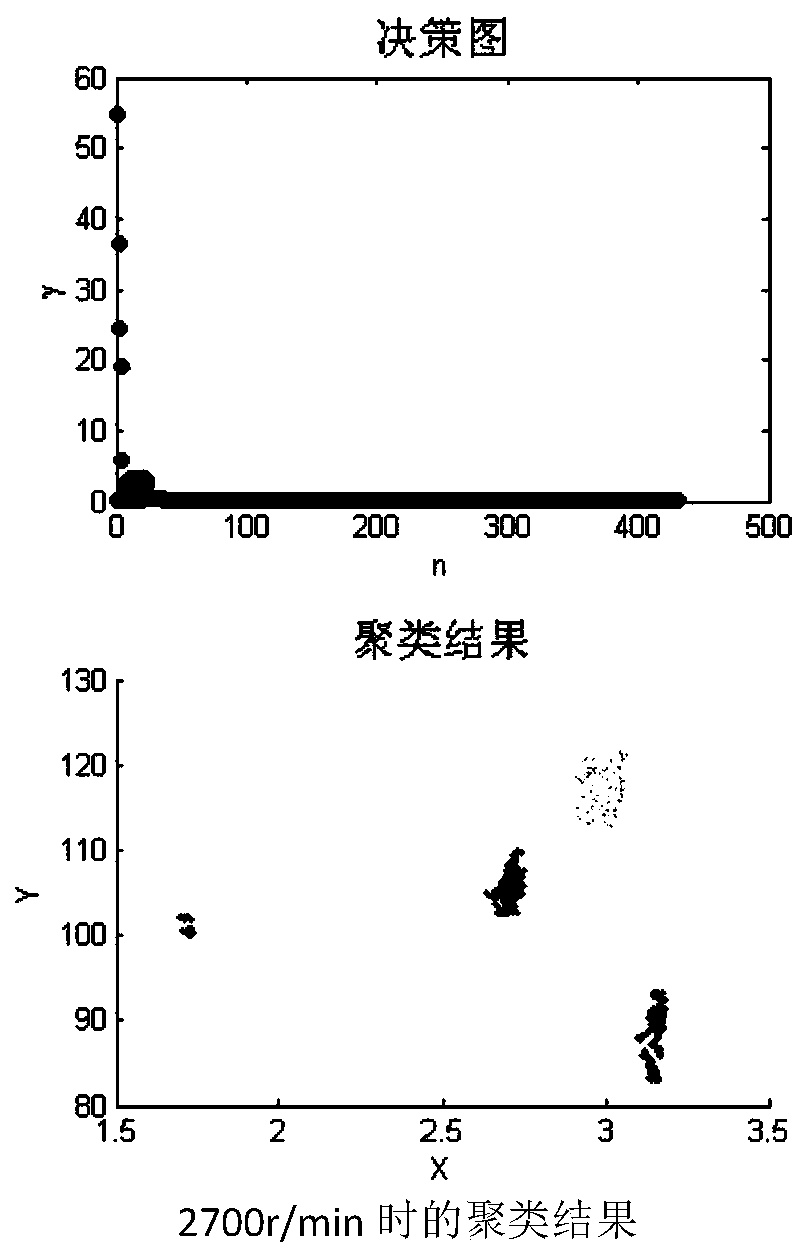

[0067] The first step is to collect the vibration acceleration signal of the aeroengine rotor; through the eddy current acceleration sensor, select the data of the aeroengine rotor speed of 2400r / min and 2700r / min, the sampling frequency is 10240HZ, the sample length is 8192, and the number of samples is 1525 groups; implement In the case, the signal collected by the acceleration sensor in the horizontal direction of the left casing is selected. The signal is a discrete vibration acceleration signal. Since there may be errors at the beginning and end of each group of signals, in signal processing and calculation, only each group is used. The 5120 data in the middle section of the group data, and finally mainly adopt the relatively stable state of the comprehensive state of the rotor, and analyze the data. There are 151 groups of data in the normal state, 100 gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com