Motor controller

A control device and motor technology, applied in motor control, non-electric variable control, computer control, etc., can solve the problems of notch filter's step response overshoot and unsatisfactory processing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

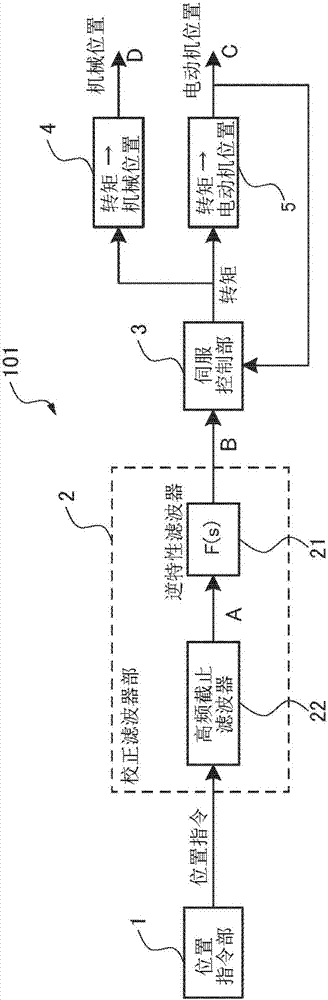

[0015] Next, a motor control device according to the present invention will be described with reference to the drawings.

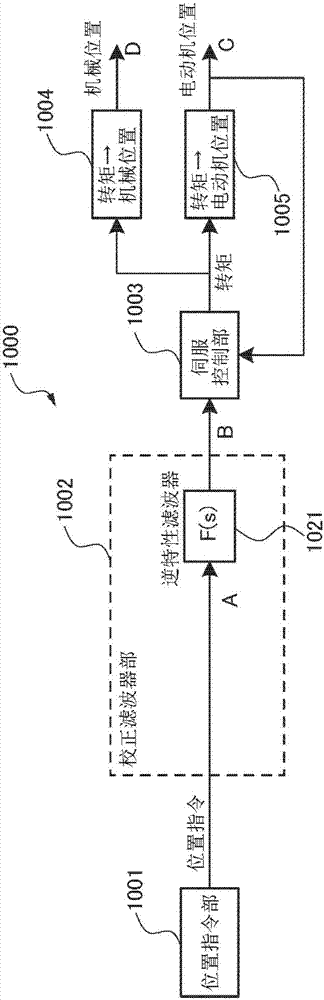

[0016] First, an invention related to the present invention and an invention related to a related application filed by the applicant (Japanese Patent Application No. 2015-007219) will be described. exist figure 1 , a block diagram of a motor control device according to an invention related to the present invention is shown. The motor control device according to this related invention is a motor control device that corrects a position command using an inverse characteristic filter F(s) from a motor position to a machine position.

[0017] figure 1 The motor control device 1000 shown has a position instruction unit 1001, a correction filter unit 1002, a servo control unit 1003, an element 1004 representing a transfer characteristic from torque to a machine position, and an element representing a transfer characteristic from torque to a motor position 1005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com