Powder cleaning device of remanufactured toner cartridge

A technology for cleaning powder and toner cartridges, which is applied in the fields of electrical recording, optics, instruments, etc., can solve problems such as affecting the health of operators, high labor intensity, and affecting printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

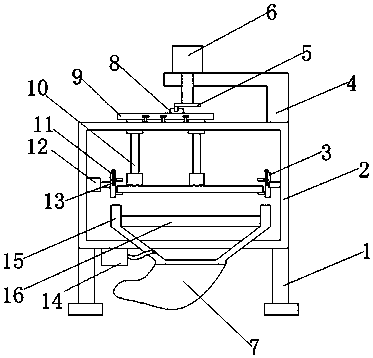

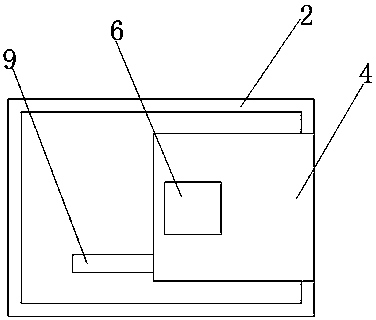

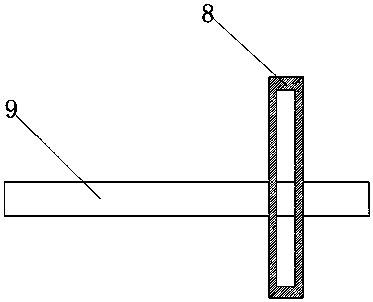

[0019] Example 1, in order to achieve the purpose of cleaning the toner cartridge, the toner cartridge is placed on the side of the first fixing plate 3, one end of the screw 11 extends into the through hole at the top of the first fixing plate 3, and the screw 11 is movably clamped in the through hole , the screw 11 can only rotate by itself and cannot move up and down. When the screw 11 is rotated, the screw 11 and the pressure plate 13 mesh with each other, and the screw 11 drives the pressure plate 13 to move downward. At the current position, connect the power supply to start the second motor 12, the second motor 12 drives the first fixed plate 3 to rotate, the first fixed plate 3 drives the toner cartridge to rotate, then connect the power again, start the first motor 6, and the first motor 6 drives the rotating disk 5 rotates, because one end of the matching rod on one side of the rotating disk 5 extends to the inside of the limit bar 8, the matching rod on the rotating ...

Embodiment 2

[0020] Embodiment 2, in order to achieve the purpose of collecting the powder, connect the power supply, turn on the suction pump 14, the strong suction of the suction pump 14 makes the powder flow through the filter screen 16, and flow into the collection bag 7. The cross section of the second support 15 is an isosceles trapezoid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com