Formation method for irregularly-shaped hole of printed circuit board

A molding method and technology of special-shaped boards, which are applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as easy deformation, slot length, etc., to reduce the amount of dust, solve serious burrs, and improve hole positions The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

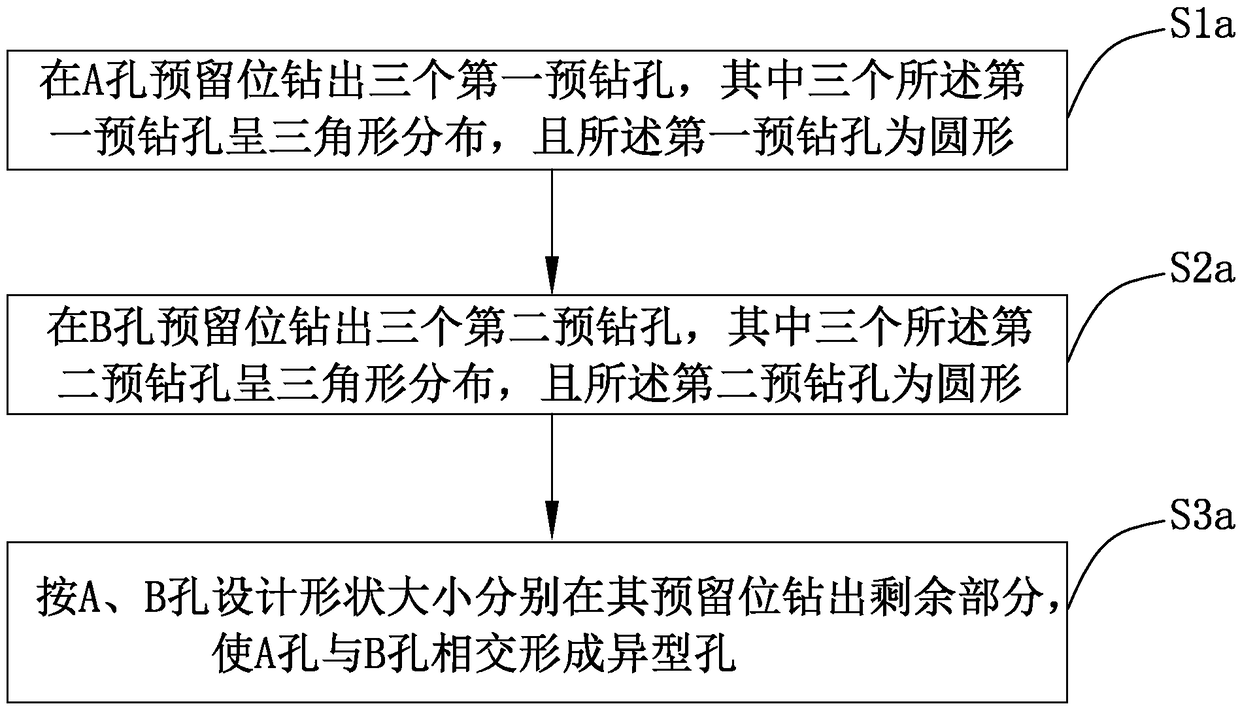

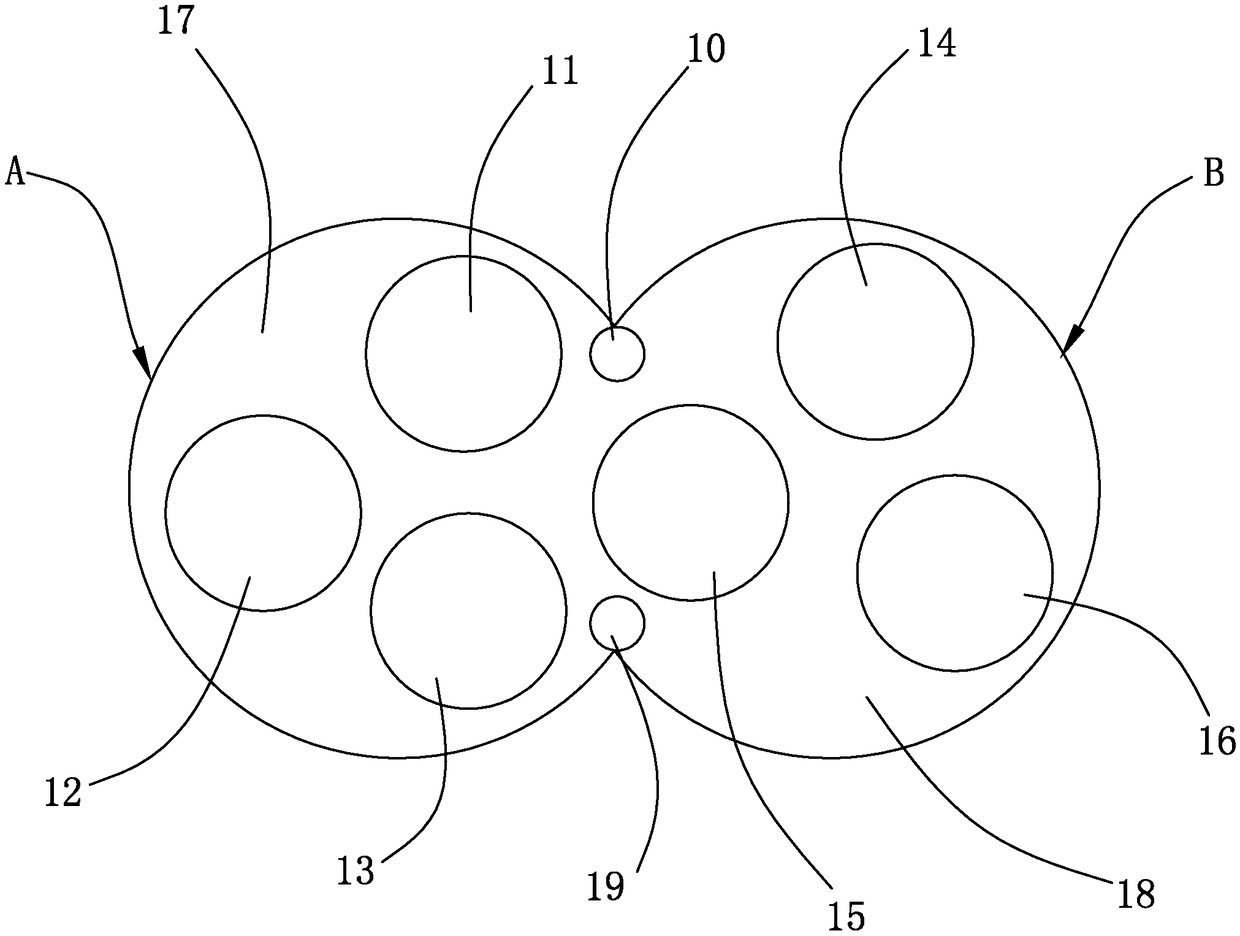

[0052] In this embodiment, hole A and hole B are circular holes respectively. Please refer to figure 1 and figure 2 ,in figure 1 The block flow diagram of Embodiment 1 of the forming method of the printed circuit board special-shaped hole provided by the present invention; figure 2 It is a schematic diagram of superimposing all drilled holes in the process of machining special-shaped holes using the molding process of Example 1.

[0053] A method for forming a special-shaped hole in a printed circuit board, comprising the steps of:

[0054] Step S1a, drill three first pre-drilled holes 11 / 12 / 13 in the reserved position of hole A, wherein the three first pre-drilled holes 11 / 12 / 13 are distributed in a triangle, and the first pre-drilled holes 11 / 12 / 13 are circular respectively;

[0055] Specifically, the three first pre-drilled holes 11 / 12 / 13 are located in the reserved position of the A hole, and the area of the three first pre-drilled holes 11 / 12 / 13 is smaller than ...

Embodiment 2

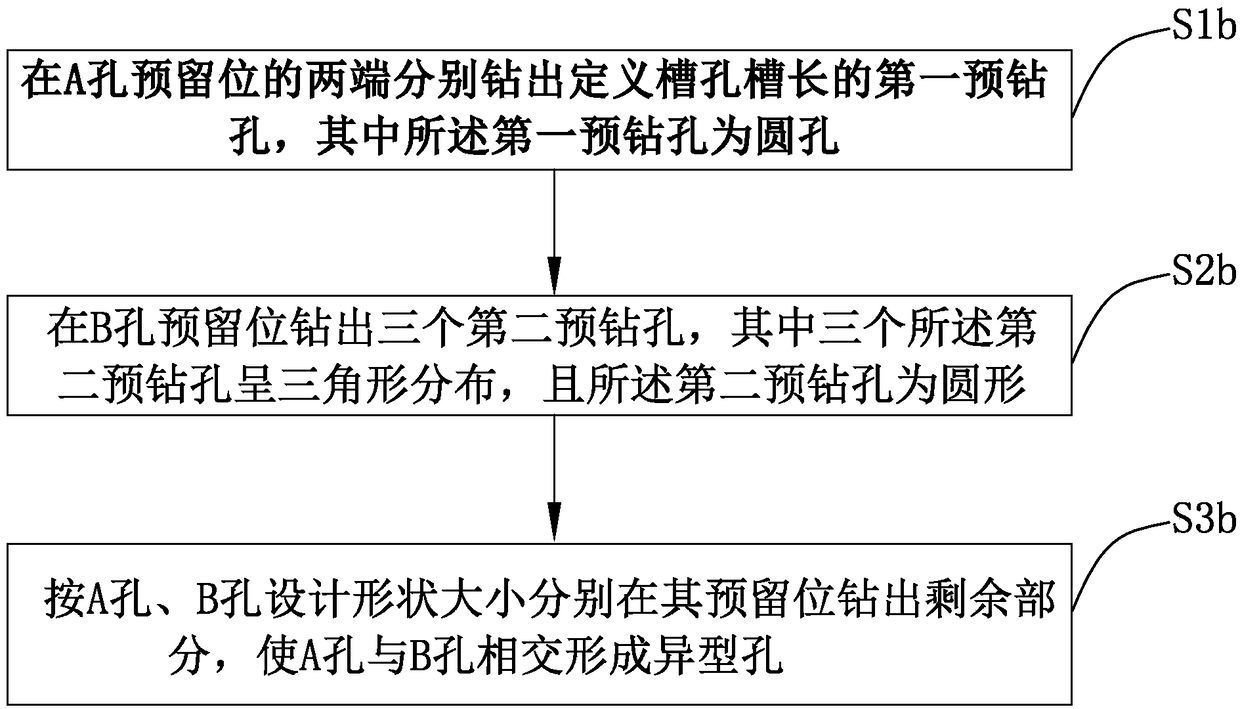

[0064] In this embodiment, hole A is a slotted hole, and hole B is a round hole. Please refer to image 3 , Figure 4 ,in image 3 The block flow diagram of Embodiment 2 of the forming method of the printed circuit board special-shaped hole provided by the present invention; Figure 4 It is a schematic diagram of superimposing all drilled holes during the machining of special-shaped holes using the molding process of Example 2.

[0065] A method for forming a special-shaped hole in a printed circuit board, comprising the steps of:

[0066] Step S1b, drill the first pre-drilled holes 21 / 22 defining the slot length at the two ends of the reserved position of hole A respectively, wherein the first pre-drilled holes 21 / 22 are round holes;

[0067] Specifically, the first pre-drilled hole 21 / 22 is located in the reserved position of the A hole, preferably, the first pre-drilled hole 21 / 22 is partially tangent to the A hole;

[0068] Step S2b, drilling three second pre-drilled...

Embodiment 3

[0076] In this embodiment, hole A and hole B are respectively slotted holes. Please refer to Figure 5 , Figure 6 ,in Figure 5 The block flow diagram of Embodiment 3 of the forming method of the printed circuit board special-shaped hole provided by the present invention; Figure 6 It is a schematic diagram of superimposing all drilled holes in the process of machining special-shaped holes using the molding process of Example 3.

[0077] A method for forming a special-shaped hole in a printed circuit board, comprising the steps of:

[0078] Step S1c, respectively drill the first pre-drilled holes 31 / 32 defining the length of the slot at the two ends of the reserved position of hole A, and the first pre-drilled holes 31 / 32 are round holes;

[0079] Specifically, the first pre-drilled hole 31 / 32 is located in the reserved position of the A hole, preferably, the first pre-drilled hole 31 / 32 is partially tangent to the A hole;

[0080] Step S2c, drill out the second pre-dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com