A pipe joint automatic plugging and unplugging device

A technology of automatic plugging and unplugging, pipe joints, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as high resistance, limited application occasions, and inability to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

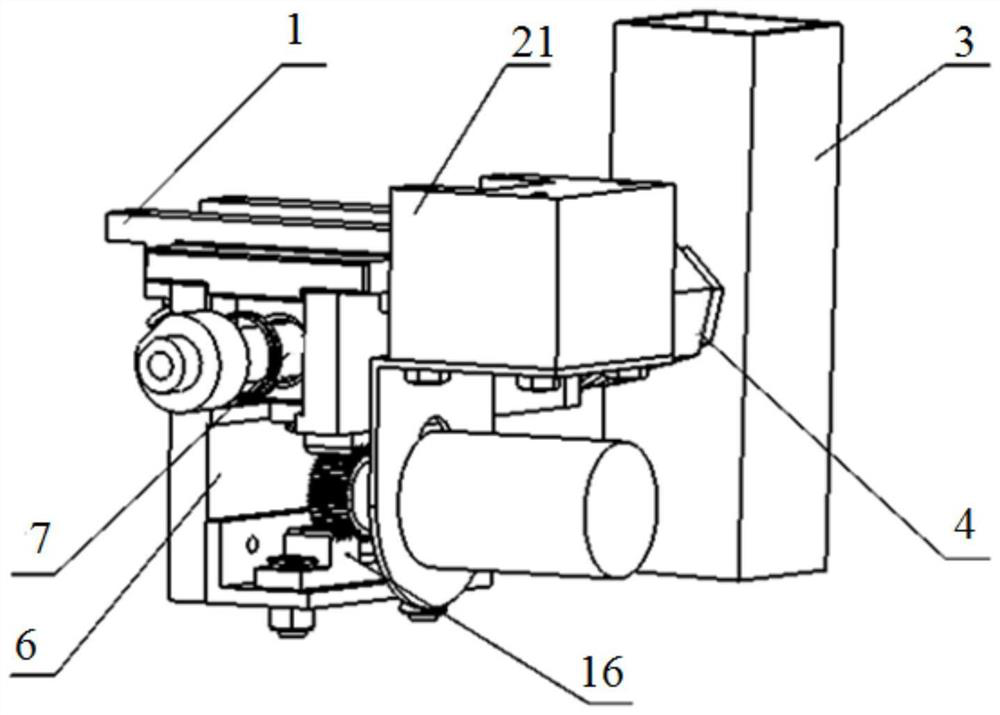

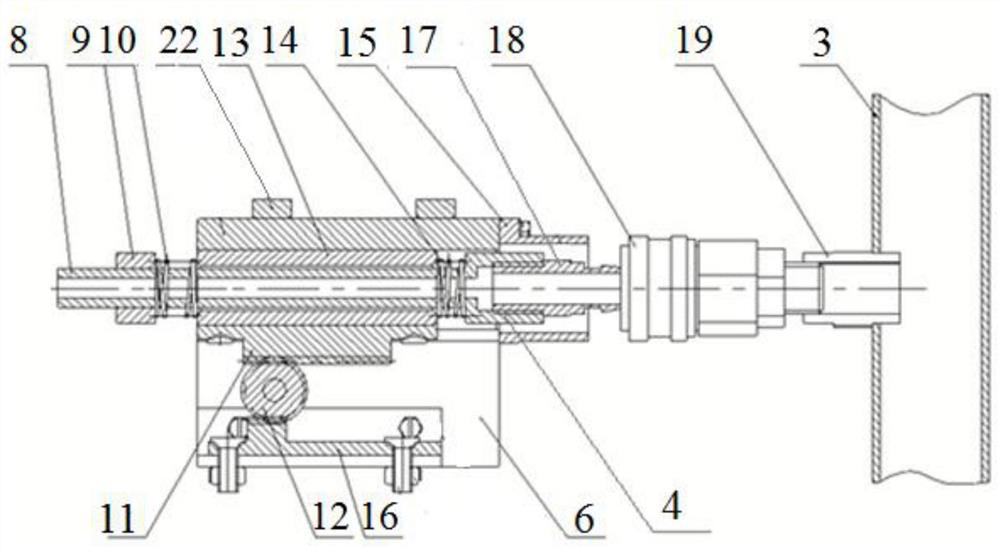

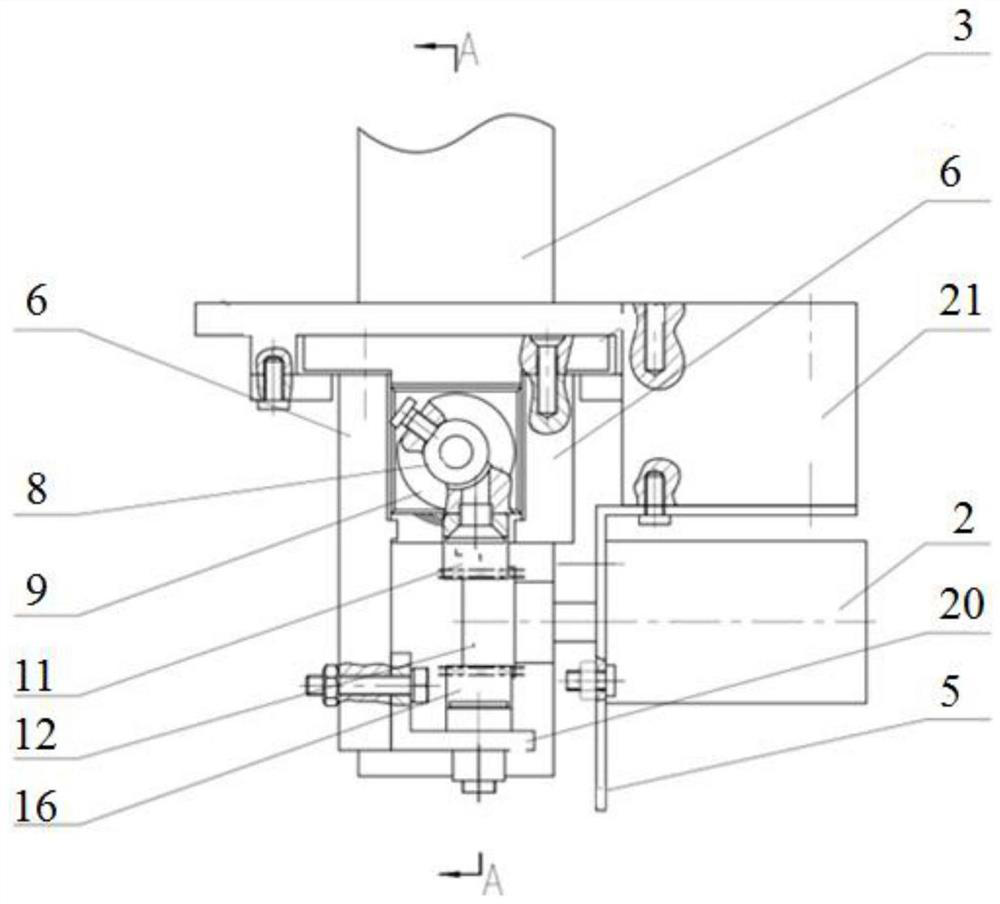

[0034] The present invention is an automatic plugging and unplugging device for pipe joints, such as figure 1 , figure 2 and image 3 shown, including movable joints and fixed joints;

[0035] The moving joint includes a DC motor 2, the output shaft of the DC motor 2 is sleeved with a drive gear 12, the upper end of the drive gear 12 meshes with a linear structure process rack 11, the lower end of the drive gear 12 engages with a linear structure return rack 16, and the process rack 11 Connect the inner sleeve 13, the inner sleeve 13 is sleeved with the inner water pipe mechanism 7, the return rack 16 is connected to the outer shell structure 6 through the rack mounting frame 20, the outer shell structure 6 is socketed outside the inner sleeve 13, and the outer shell structure 6 is close to the fixed joint One end is connected to the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com