Water transfer printing device

A technology of water transfer printing and water tank, which is applied in transfer printing, rotary printing machine, printing, etc., can solve the problems of low efficiency and unfavorable health of workers, so as to improve efficiency, facilitate batch water transfer printing processing, and protect human health Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

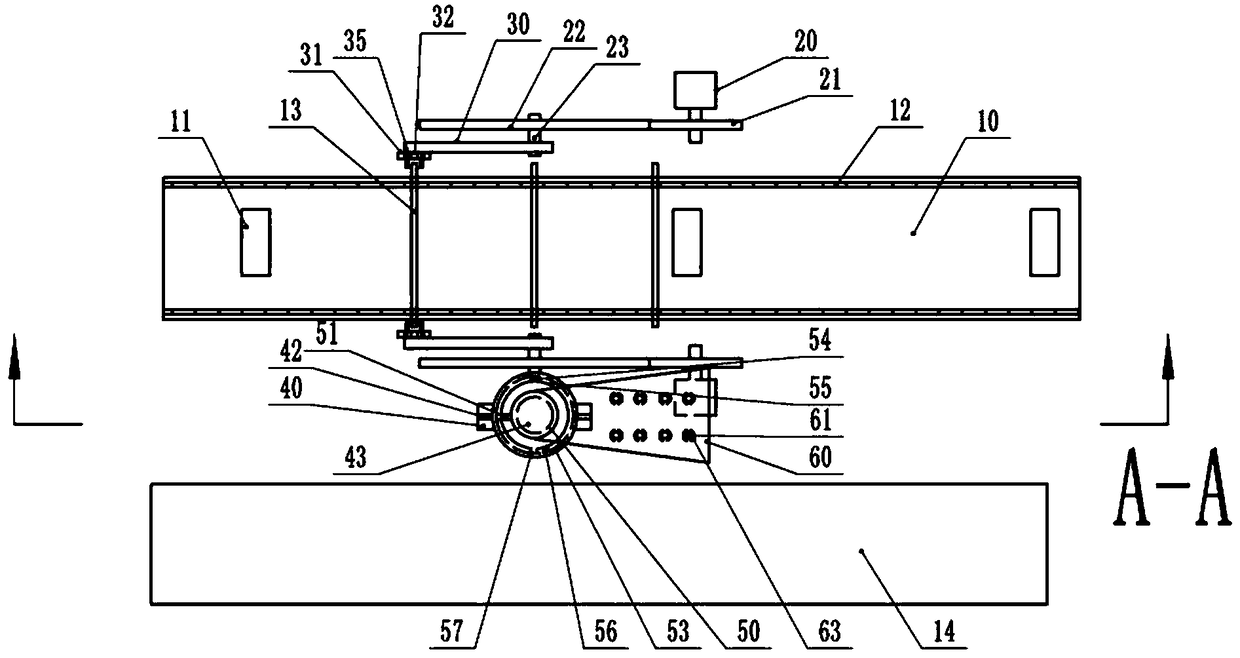

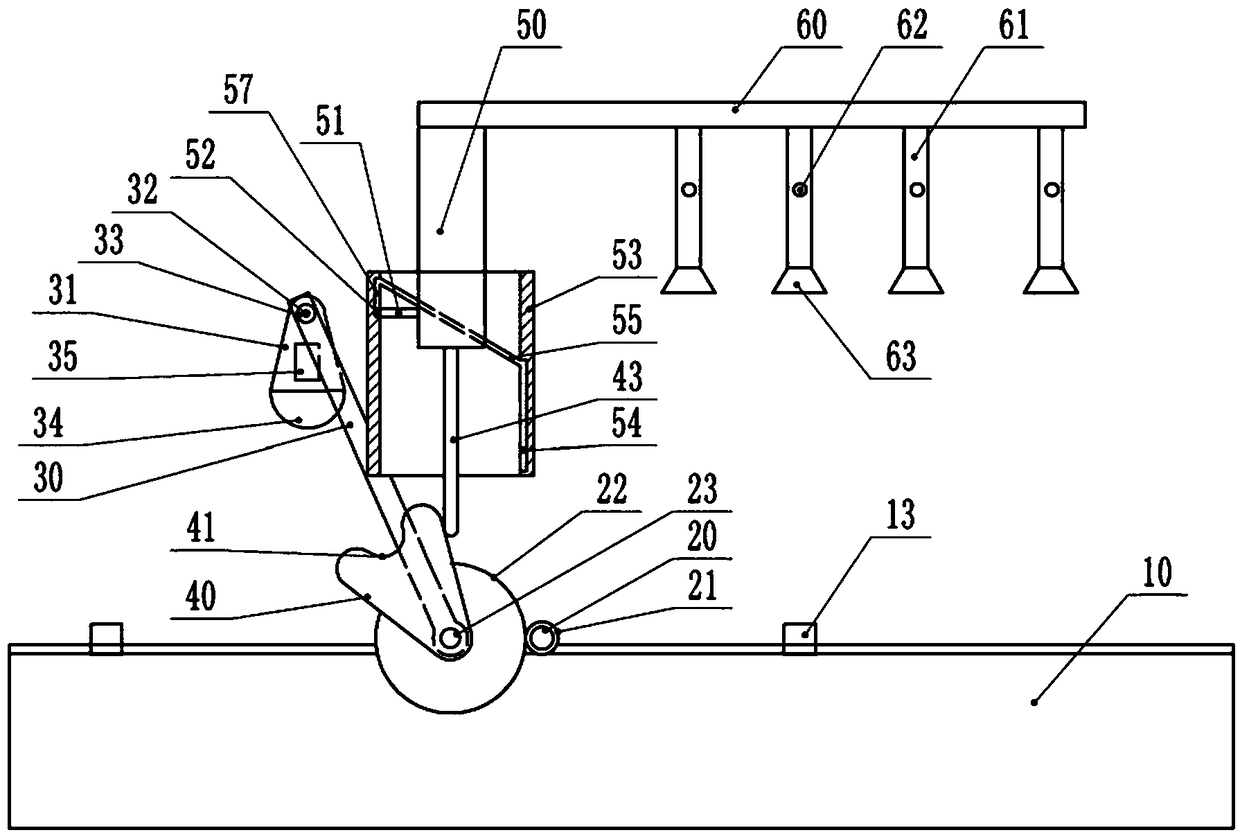

[0025] The reference signs in the accompanying drawings of the description include: water tank 10, roller 11, transmission chain 12, partition bar 13, conveyor belt 14, motor 20, main gear 21, slave gear 22, rotating shaft 23, rotating rod 30, support plate 31, short Shaft 32, bearing 33, counterweight 34, cavity 35, cam 40, groove 41, ring groove 42, slide bar 43, pole 50, slide bar 51, ball 52, sleeve 53, vertical groove 54, circle Ring groove 55, switch 56, short groove 57, grasping plate 60, telescopic rod 61, buckle 62, suction cup 63, figure 1 with figure 2 The middle frame, air pump and air pipe are not shown.

[0026] Such as figure 1 , figure 2 As shown, a water transfer printing device includes a water tank 10, a frame and a conveyor belt 14 parallel to the water tank 10. The bottom of the water tank 10 is provided with a roller 11 that drives the water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com