System and method for measuring hyper-velocity impact debris cloud three-dimensional structure

A three-dimensional structure, ultra-high-speed technology, used in the testing of machine/structural components, measuring devices, impact testing, etc., can solve the problems of blockade, short exposure time, expensive equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical means, creative features, workflow, and usage methods of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

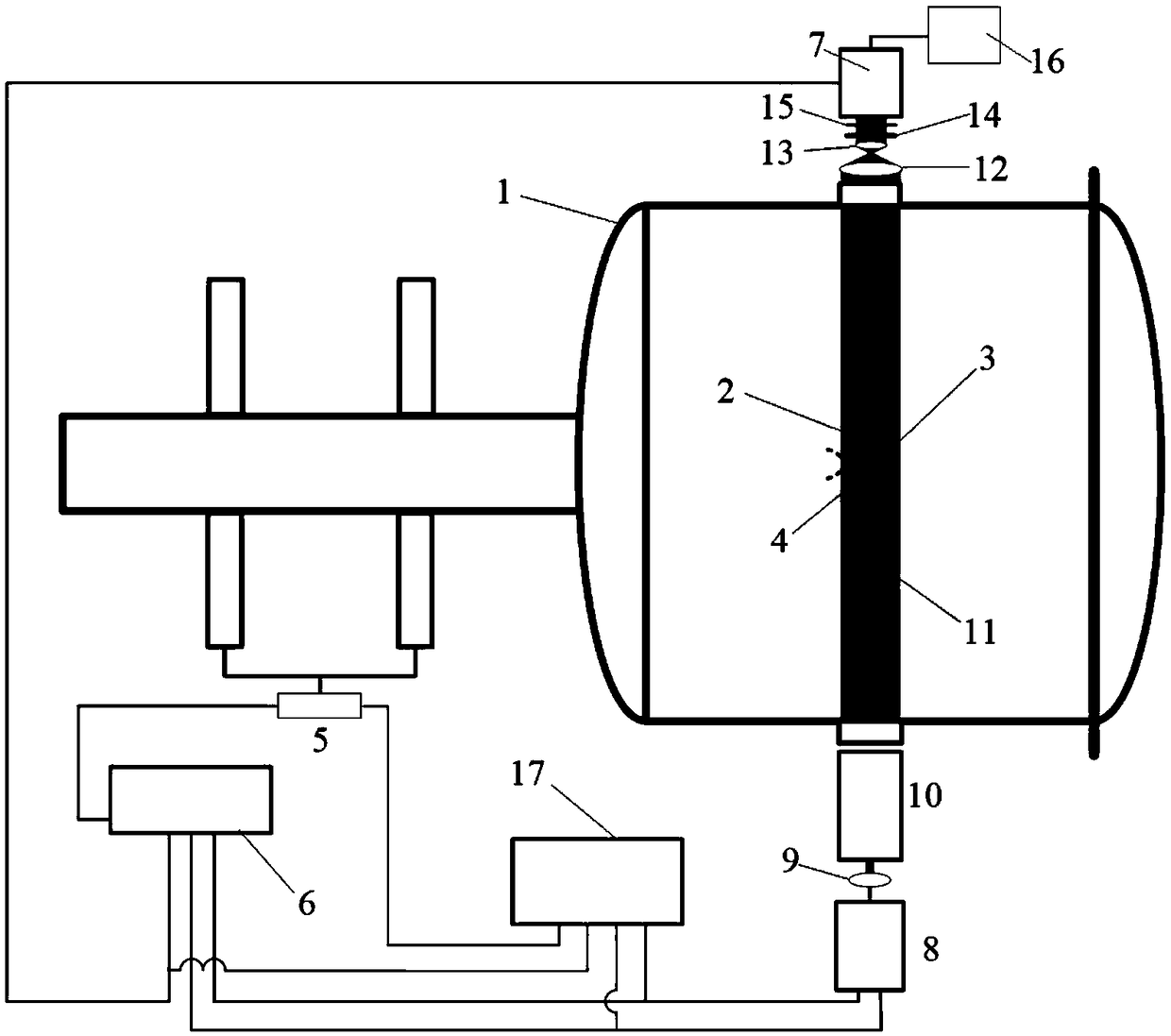

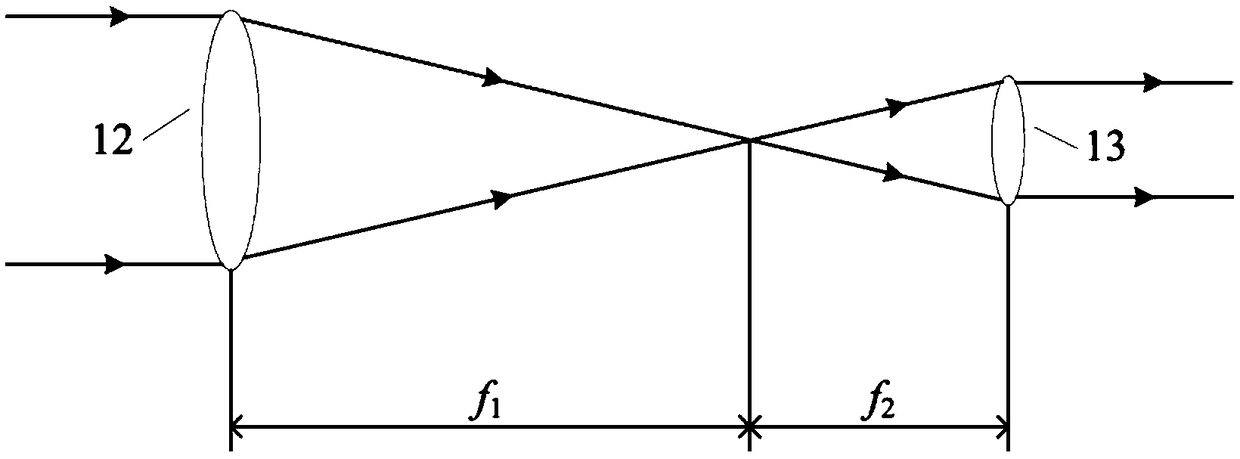

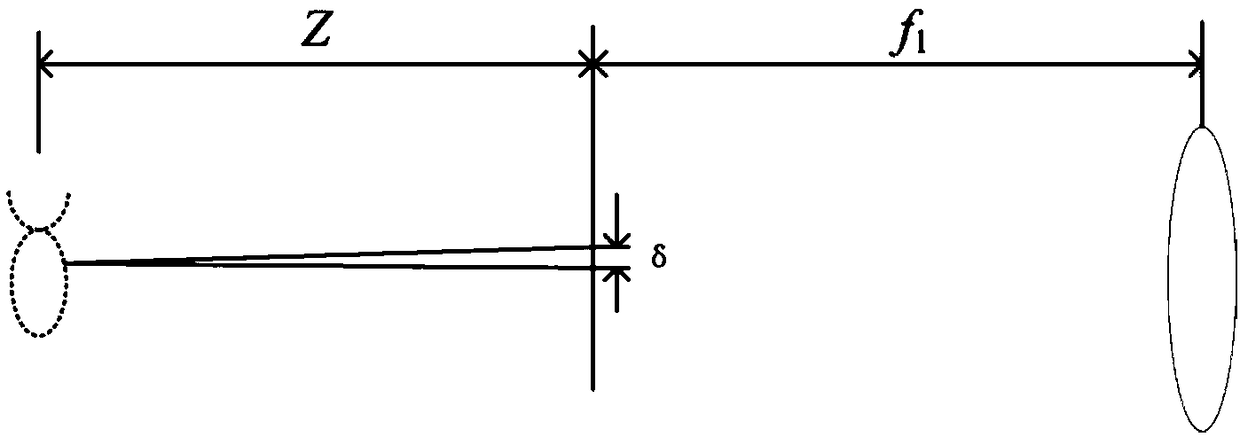

[0044] Such as figure 1 As shown, the system for measuring the three-dimensional structure of ultra-high-speed collision debris cloud in this embodiment includes a target chamber 1, a target surface 2, an observation plate 3, a debris cloud 4, a speedometer 5, a digital time-delay generator 6, a CCD camera 7, a nanometer Second level pulse laser 8, lens 9, beam expander 10, parallel light beam 11, lens 12, lens 13, 532nm bandpass filter 14, neutral filter 15, computer 16 and oscilloscope 17. The lens 12 and the lens 13 form a first lens module, and the lens 9 is a second lens module.

[0045] Among them, the velocity of the ultra-high-speed impact test projectile is as high as 3-8km / s, and the velocity of the debris cloud 4 generated by the collis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com