Motor rotors and permanent magnet motors

A technology for motor rotors and permanent magnet motors, applied in magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of reduced motor efficiency, large charging and demagnetizing currents, and difficult adjustment of magnetic fields, so as to improve the equivalent coercive force and improve Effect of demagnetizing current and improving motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

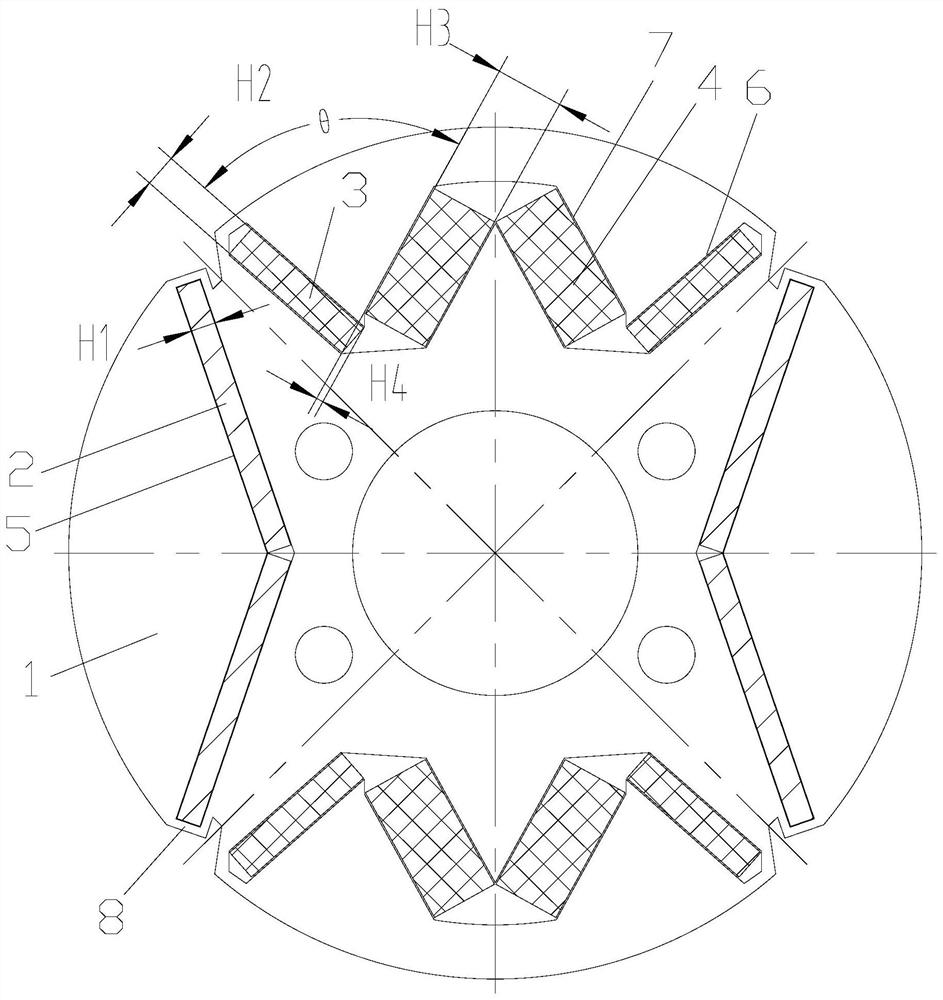

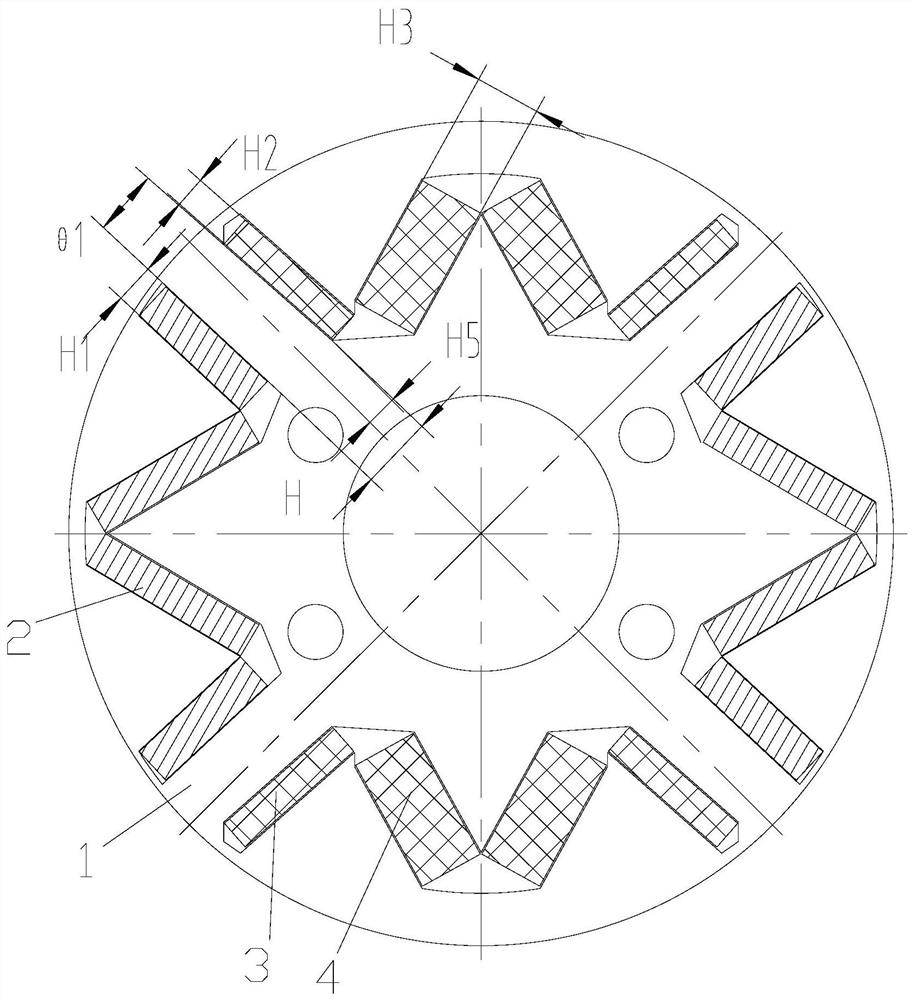

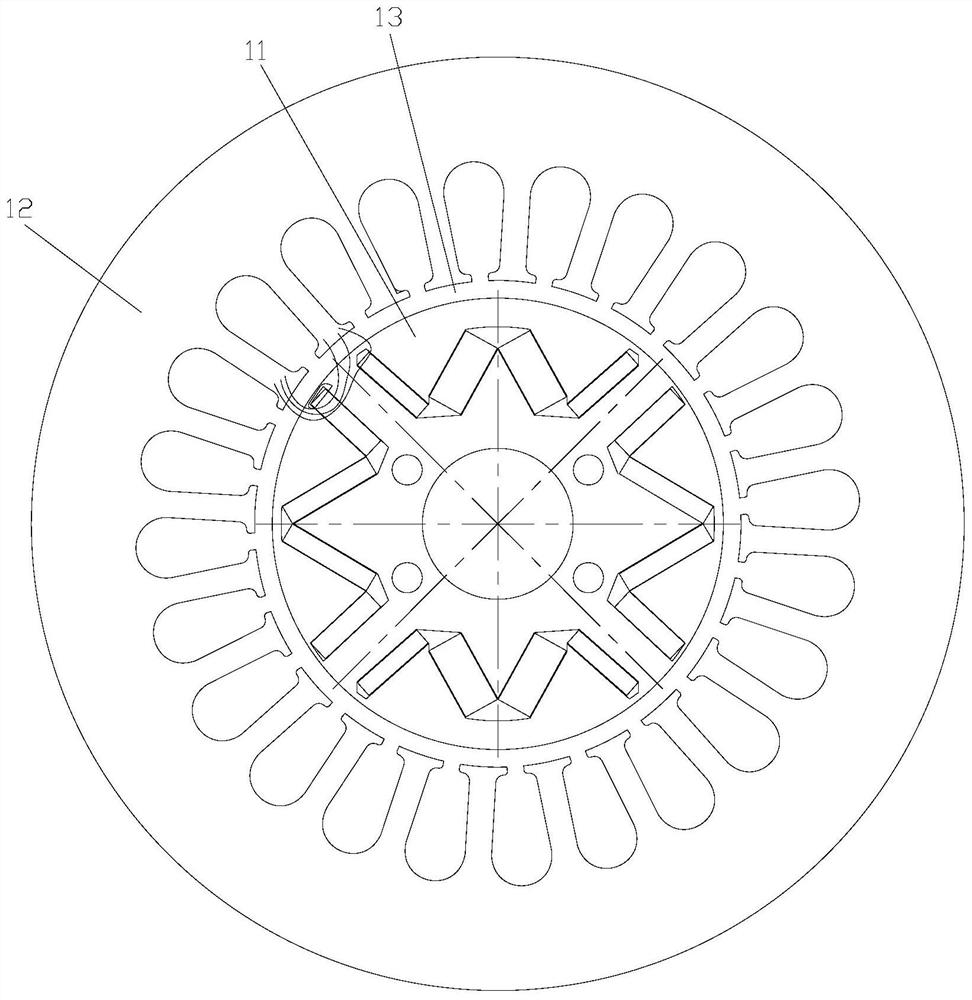

[0046] see in conjunction Figures 1 to 8 As shown, according to the embodiment of the present invention, the motor rotor includes a rotor core 1 and first permanent magnet poles and second permanent magnet poles arranged alternately along the circumferential direction of the rotor core 1, and the alignment of the permanent magnets on the first permanent magnet poles The coercive force is higher than the coercive force of the permanent magnet on the second permanent magnet pole.

[0047] The above-mentioned permanent magnet is, for example, magnet steel.

[0048] The permanent magnets on the first permanent magnet pole and the permanent magnets on the second permanent magnet pole adopt at least two types of magnetic steel grades with coercivity respectively, so that permanent magnet structures with different coercive forces are formed on the two permanent magnet poles. The permanent magnet structures with different coercivity are located at different magnetic poles, so the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com