Method for setting up a rotary processing machine and rotary processing machine

A processing machine tool and turning technology, which is applied in the field of setting up turning machine tools and turning machine tools, can solve the problems of expensive, expensive setting, error-prone, etc., and achieve the effect of low cost and fast method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

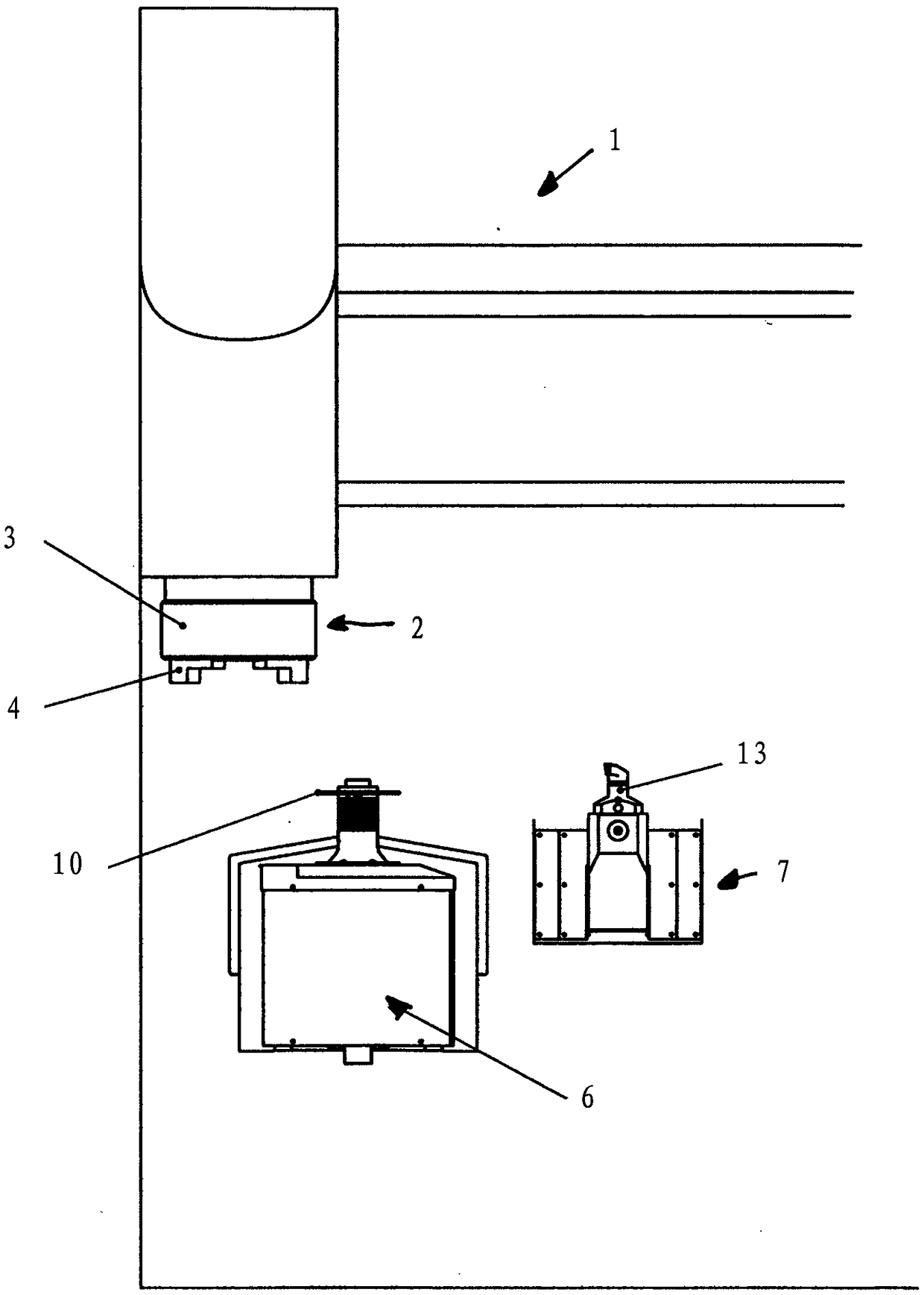

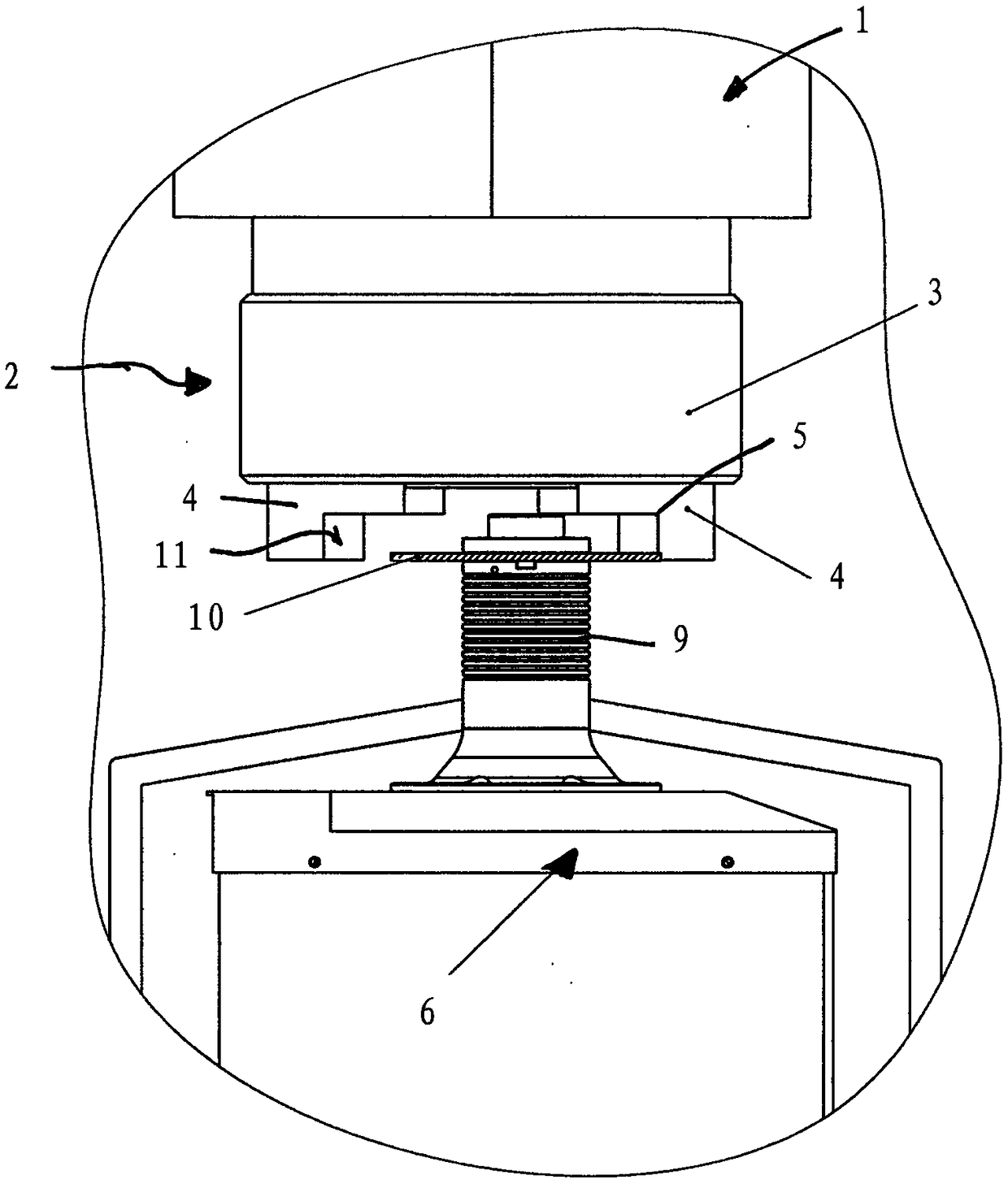

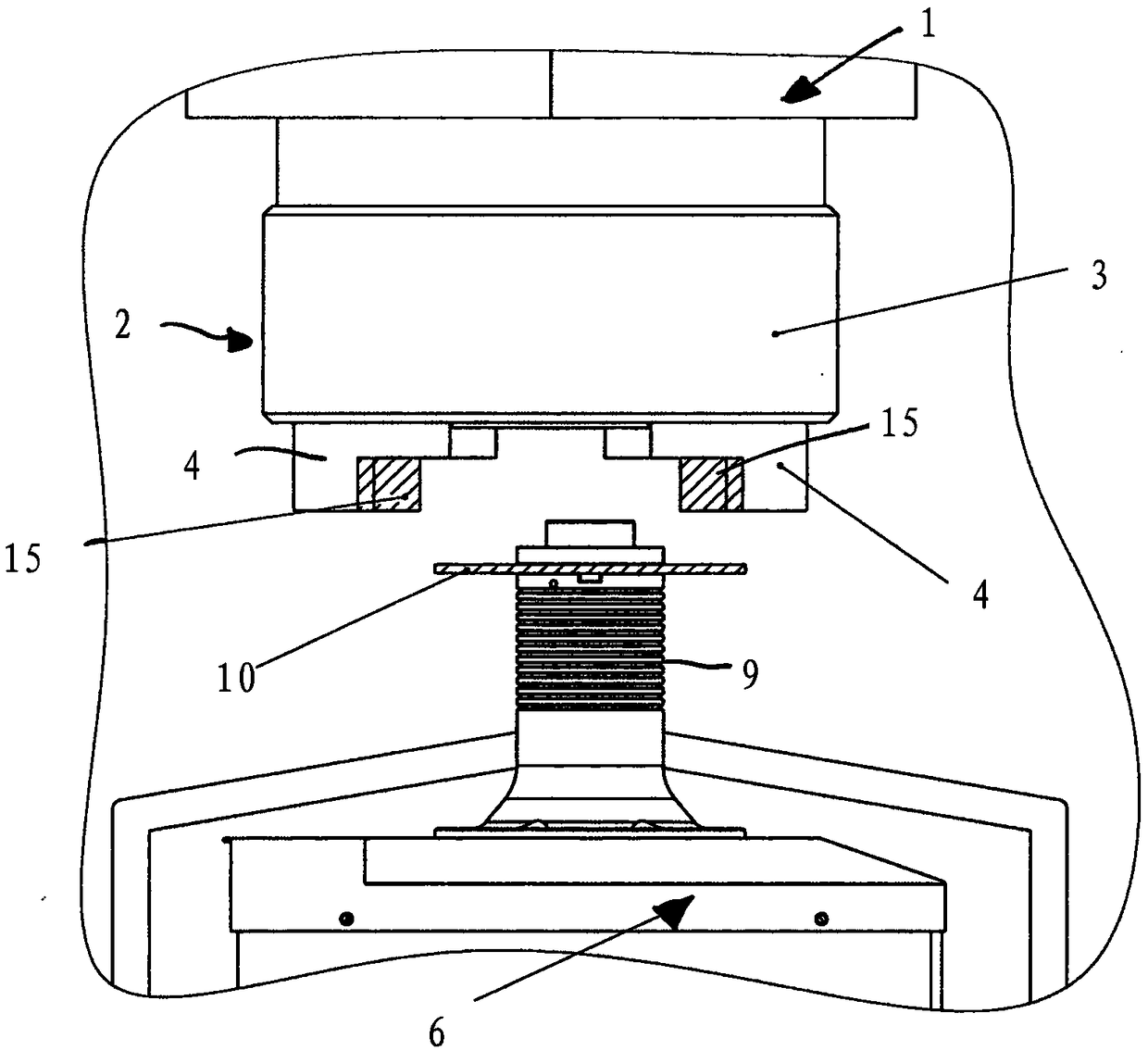

[0040] figure 1 A turning machine tool according to the invention, denoted as a whole by 1 , hereinafter referred to simply as a lathe, is shown. The lathe 1 has a workpiece holder 2 which is designed, for example, as a so-called three-jaw lathe chuck 3 . On the lathe chuck 3 three base jaws 4 are arranged radially at an angular distance of 120° from one another, of which only two base jaws 4 are shown in the figure for a better overview.

[0041] The base jaw 4 mainly has a square shape extending in the radial direction and has an axial step 5 . The base jaw 4 can be oriented in the radial direction on the lathe chuck 3 in order to clamp a workpiece. Such a base jaw 4 is a standard part of the lathe 1 and is available in different shapes and embodiments. Therefore, there are also base jaws 4 without axial steps 5 , or base jaws 4 with two or more axial steps 5 . Likewise, lathe chucks 2 with more than three base jaws 4 also exist.

[0042] Furthermore, the lathe 1 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com