Drive unit

A technology of drive unit and drive slot, which is applied in the direction of automatic control devices, machine tool parts, precision positioning equipment, etc., to achieve the effects of improving efficiency and service life, reducing energy consumption, and suppressing undesired movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

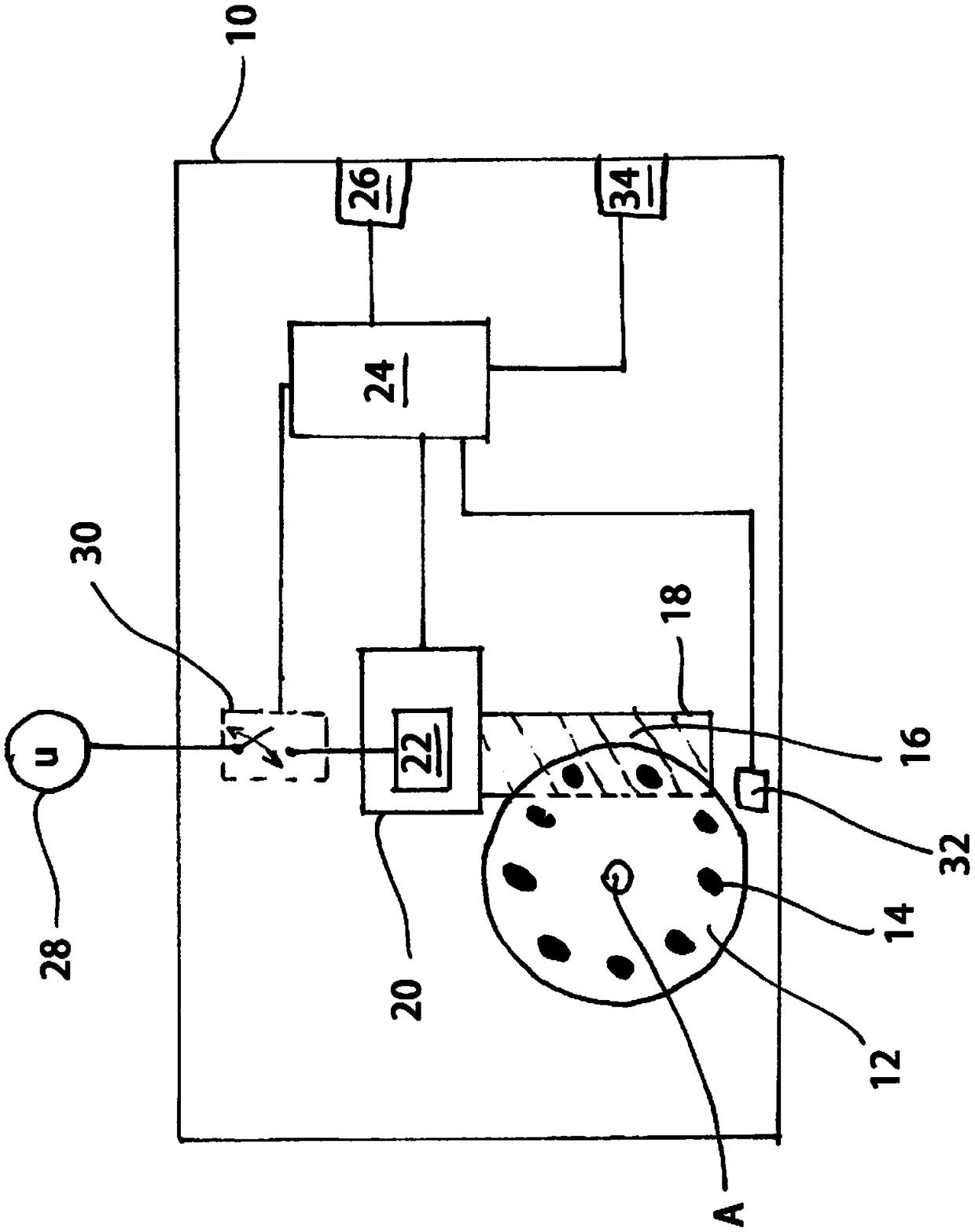

[0032] The drive unit 10 , here in particular a rotary indexing table, comprises a transfer element which is configured as a turntable 12 and is rotatable about an axis A extending perpendicularly to the plane of the drawing. The turntable 12 has a plurality of entrainers 14 which are distributed in the circumferential direction and which, depending on the rotational position of the turntable 12 , engage into drive grooves of a barrel cam 18 rotatable perpendicular to the axis A.

[0033] The drive unit 10 also includes an electric drive 20 having an electric motor 22 mechanically coupled to the barrel cam 18 . The driving device 20 is electrically connected to the base control device 24 .

[0034] The base control means 24 is adapted to receive control signals for the operation of the drive unit 10 from the operator programmable user interface 26, and to output the drive signals to the drive means 20 or to apply the required current thereto in accordance with the received con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com