3D MEMS scanner for real-time cross-sectional endomicroscopy

A technology of micro-mirrors and scanning mirrors, which can be used in radiological diagnostic instruments, microscopes, and diagnostics using tomographic scanning, etc. It can solve the problems of 3D fast-axis scanning frequency limitation, high manufacturing complexity, and slow response time. , to achieve superior dynamic range, easy fiber optic connectivity, and increased imaging depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

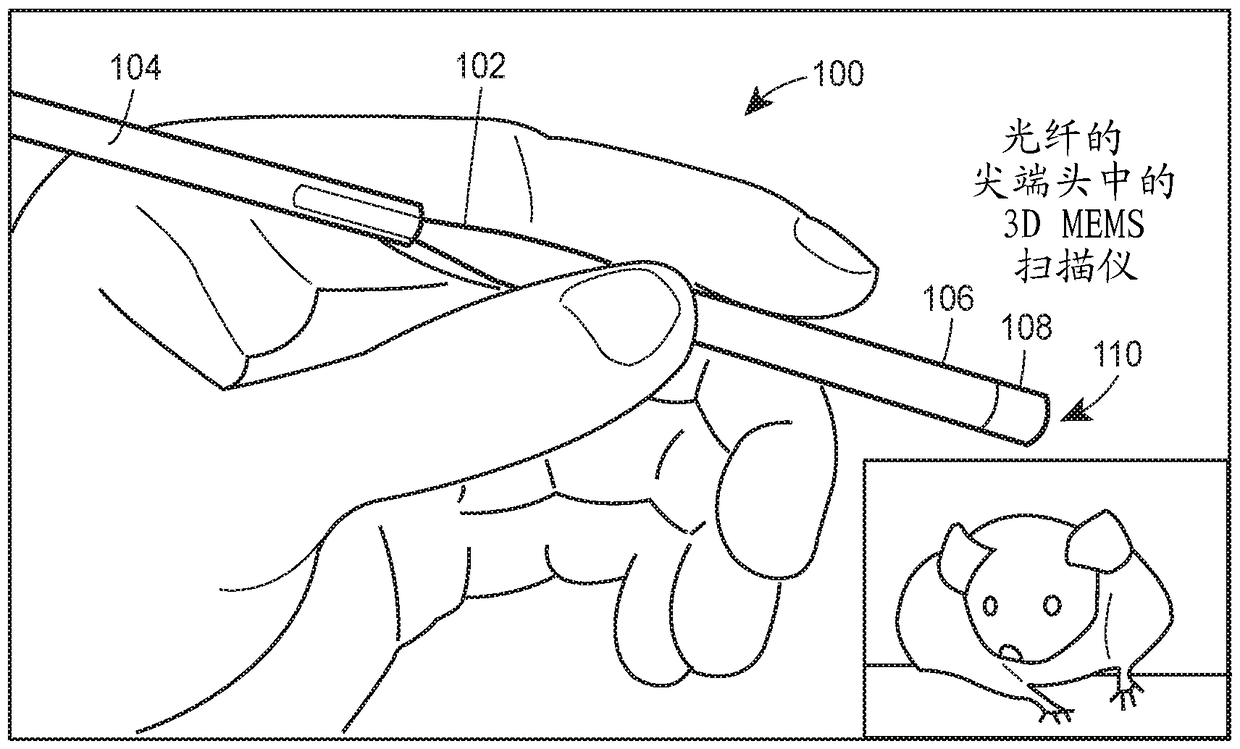

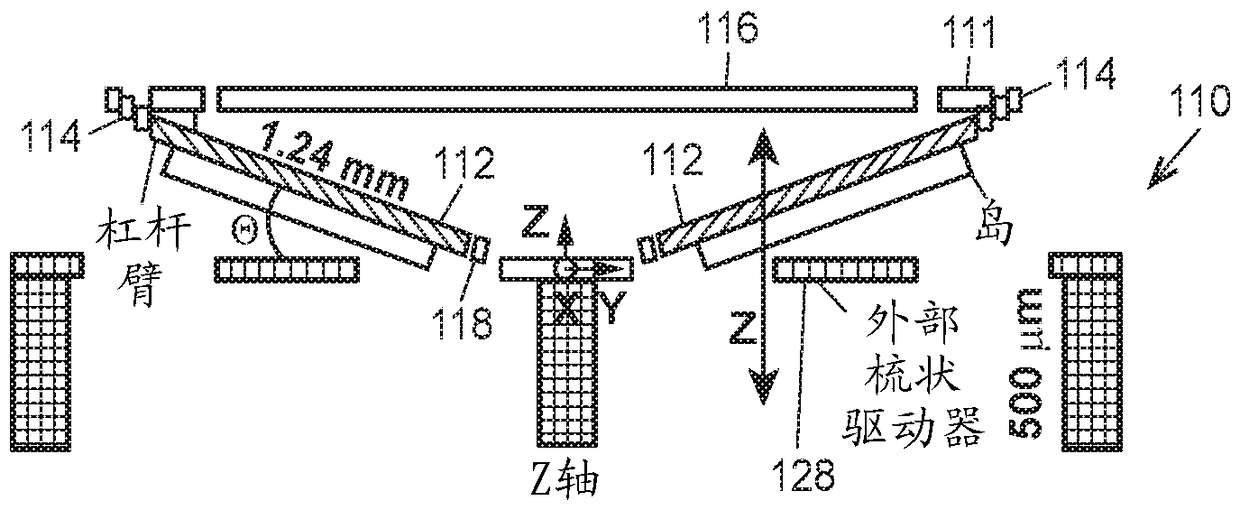

[0026] In general, in accordance with these various embodiments, techniques are provided for the design, fabrication, and implementation of a compact integrated monolithic three-dimensional (3D) MEMS scanner having dimensions that can be accommodated within an endoscopic device. In an example, a 3D MEMs scanner can be sized below about 10 x 10 mm 2 , less than about 5×5 mm 2 , below about 4×4 mm 2 and so on.

[0027]The 3D MEMS scanning techniques described herein are capable of producing both large angular deflections and out-of-plane displacements. For example, optical deflection angles greater than about ±10º, greater than about ±15º, greater than about ±25º, etc. are achievable in X-axis and Y-axis motion. The 3D MEMS scanner technology described herein can achieve such operating conditions by scanning along the z-axis at depths greater than about 200 μm, greater than about 300 μm, greater than about 400 μm, greater than about 500 μm, etc.

[0028] Scanning of full 3D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com