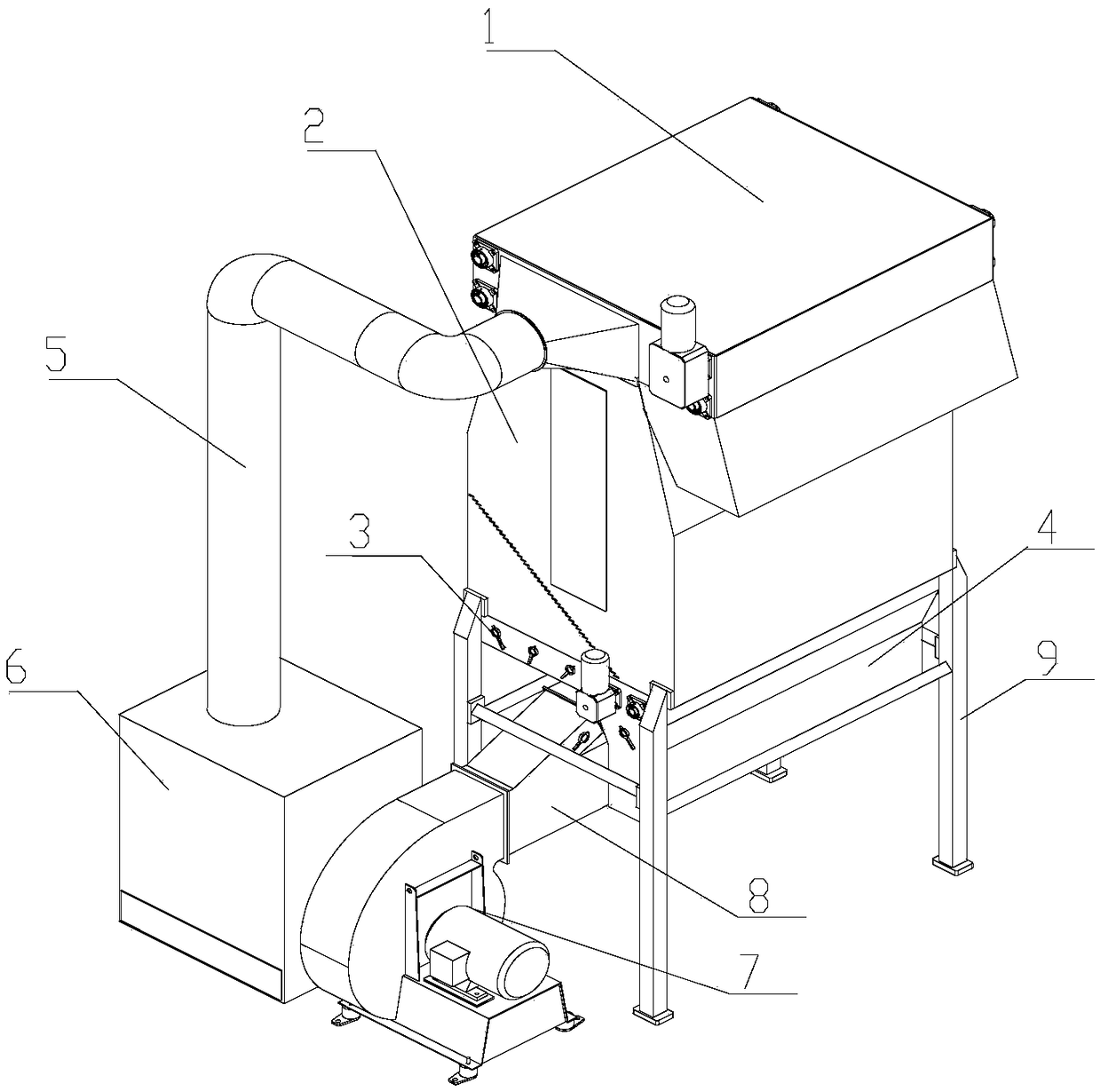

Cut tobacco processing device

A technology for processing equipment and shredded tobacco, which is applied in the fields of tobacco, tobacco preparation, and solid separation. It can solve the problems of puncturing cigarette paper, affecting the discharge temperature of shredded tobacco, and affecting the quality of shredded tobacco, so as to increase quality, avoid wet lumps, The effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

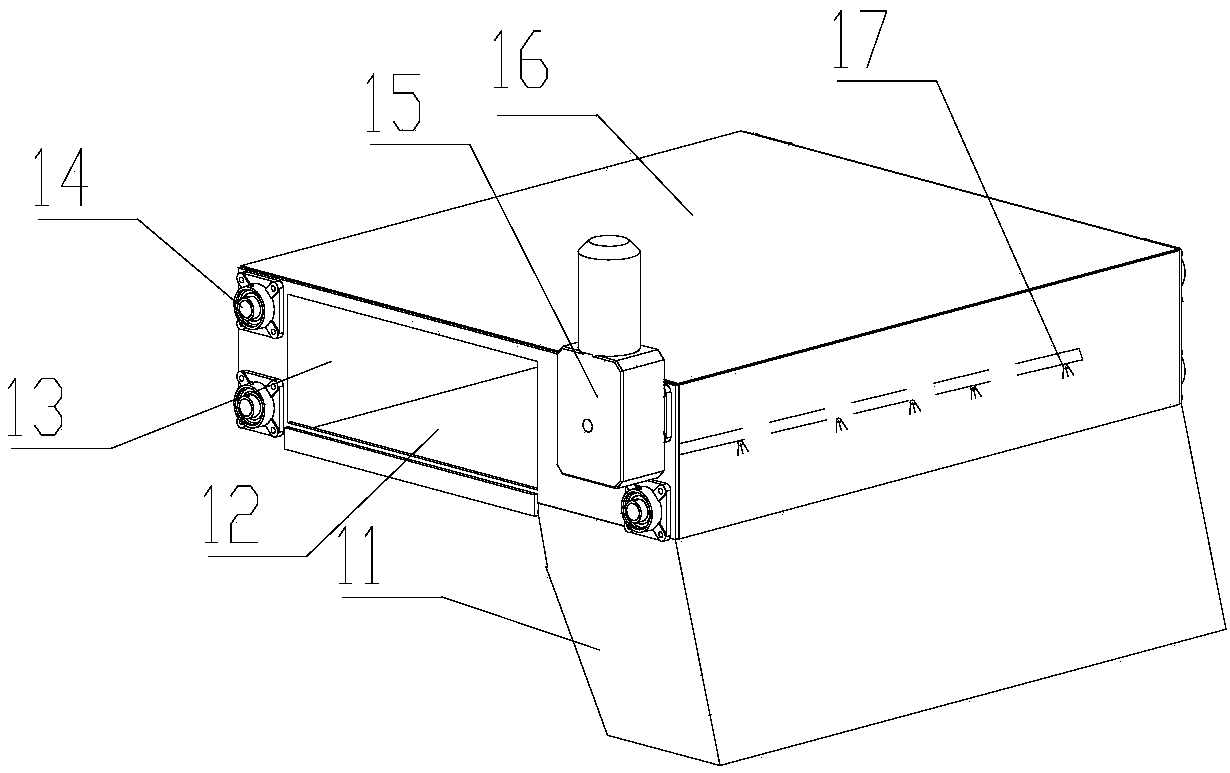

[0041] Such as figure 2As shown, the mesh belt type air-material separation device 1 described in this embodiment is a cuboid structure, including a mesh belt 12, a shroud 13, a driving roller 15, a driven roller 14, a discharge port 11, and a mesh belt cleaning device 17; A driving roller 15 and three driven rollers 14 are respectively installed on the four corners of the cuboid structure, driven by the driving device, the driving roller 15 and the driven roller 14 drive the mesh belt 12 to move towards the discharge port 11, and the mesh belt 12 It is made of stainless steel, and the surface is evenly provided with small air vents. The material cannot pass through the air vents, but will adhere to the surface of the mesh belt 12 under the blowing of the circulating wind.

[0042] The inside of the mesh-belt type air-material separation device 1 is vertically provided with two inner partitions, which are respectively placed between the driven roller 14 and the discharge port...

Embodiment 2

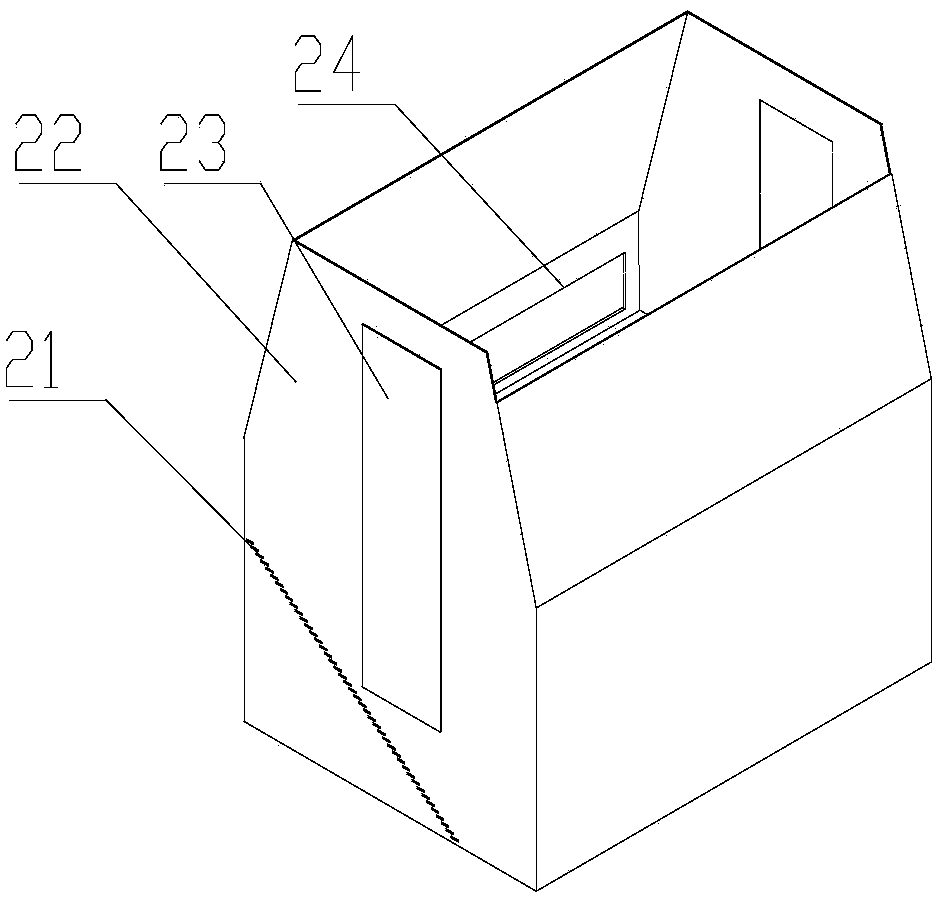

[0044] Such as image 3 As shown, the wind distribution box 2 described in the present embodiment includes a grid plate 21, a casing 22, an observation window 23, and a feed port 24, and the material enters the box body 22 through the feed port 24 and falls on the grid plate 21. Or a plurality of grid plates 21 cover the bottom of the box body 22, and the circulating air generated by the fan 7 blows upwards through the gaps between the grid plates 21 to blow the material to the mesh belt type air-material separation device 1 above.

[0045] Such as Figure 4 As shown, preferably, the grid plate is a rectangular steel plate, detachably fixed in the box, and slopes downward along the direction from the feed inlet to the lump processing device, and the included angle with the horizontal direction is 0° to 85°, The gap between adjacent grid plates 21 in the vertical direction is 0mm-100mm, and the overlapping dimension of two adjacent grid plates 21 in the horizontal direction is...

Embodiment 3

[0047] Such as Figure 5 As shown, the air equalizing box 3 includes a damper 31 and a baffle, wherein the top of the baffle is in contact with the lower part of the grille 21, and the air equalizing box 3 is divided into multiple areas, and the air volume of the circulating air is adjusted through the air door 31 in each area And wind pressure, to control the material running speed and trajectory in the wind sub-box 3. The number of the partitions is one or more, and the height of each partition is different.

[0048] The number of partitions is 1-15. The number of partitions to be used is determined according to the placement angle and height of the grid plate 21 above. The partitions are arranged from high to low in the direction of material slide. The long partitions 33 and short partitions described in the figure The baffles 34 are relatively long and short, and the top of each baffle is in contact with the grid 21 above; adjustment, a lot of interference with each othe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap