Heat-not-burn cigarette filter stick

A heat-not-burn, cigarette filter rod technology, applied in e-liquid filter, tobacco, cigar manufacturing, etc., can solve the problems of low smoke concentration, side flow smoke and environmental smoke reduction, and increase the contact area. , The effect of reducing the temperature and facilitating the circulation of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

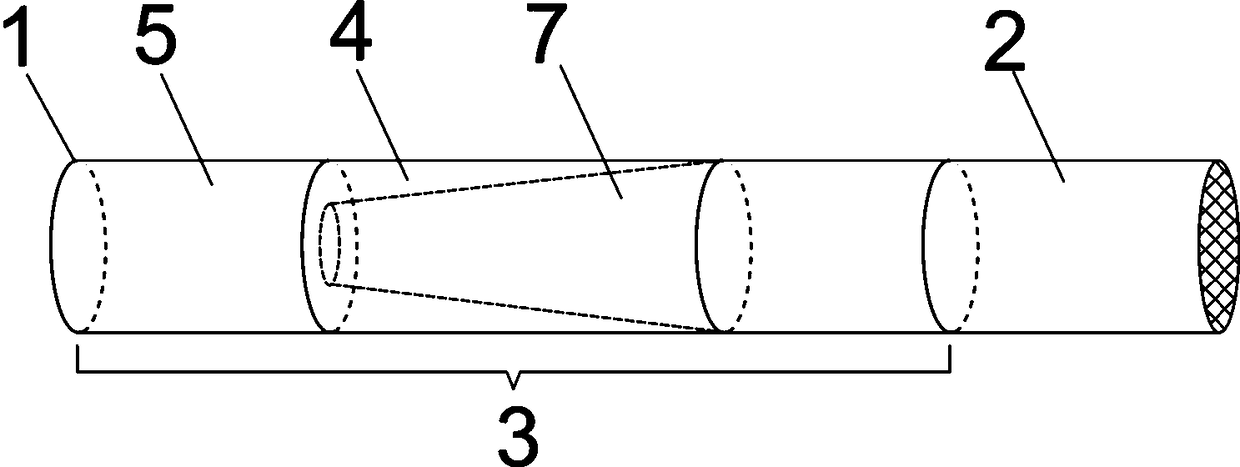

[0030] Such as figure 1 As shown, a heat-not-burn cigarette filter rod 1 includes a tobacco section 2 and a rod section 3. The rod section 3 includes a cooling part 4, a mouth contact part 5, a heat insulation part, etc., and the heat insulation part is With a hollow structure, the cooling part 4 includes at least one cavity structure 7 with different opening sizes at both ends of the cavity structure 7, wherein the large mouth end faces the tobacco section 2 and the small mouth end faces the mouth contact part 5.

[0031] When the heat-not-burn cigarette filter rod 1 is smoking, insert the tobacco section 2 into the corresponding heating device for heating. After the heating is completed, the mouth touch part 5 is smoked. The smoke enters the heat insulation part from the tobacco section 2 and gathers. Then enter the cooling part 4, and further gather and store in the cooling part 4. Since the cross-sectional area of the cooling part 4 gradually decreases along the flue gas flo...

Embodiment 2

[0033] Such as figure 1 As shown, a heat-not-burn cigarette filter rod 1 includes a tobacco section 2 and a rod section 3. The rod section 3 includes a cooling part 4, a mouth contact part 5, a heat insulation part, etc., and the heat insulation part is A hollow structure made by cutting the hollow nozzle rod, the cooling part 4 includes at least one cavity structure 7 with different opening sizes at both ends of the cavity structure 7, wherein the large mouth end faces the tobacco section and the small mouth end faces the mouth contact part.

[0034] When the heat-not-burn cigarette filter rod 1 is smoking, insert the tobacco section 2 into the corresponding heating device for heating. After the heating is completed, the mouth touch part 5 is smoked. The smoke enters the heat insulation part from the tobacco section 2 and gathers. Then enter the cooling part 4, and further gather and store in the cooling part 4. Since the cross-sectional area of the cooling part 4 gradually dec...

Embodiment 3

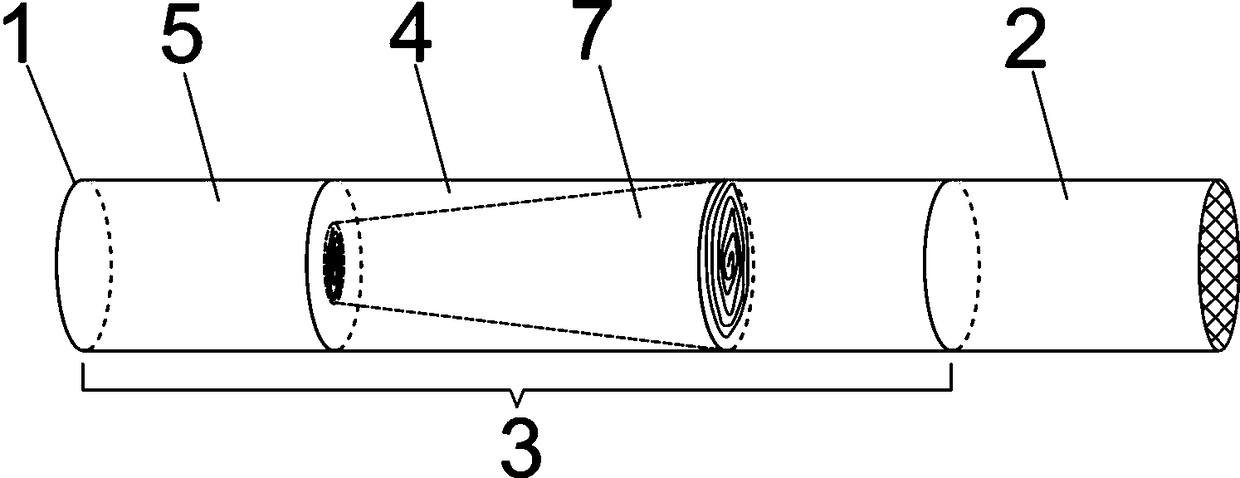

[0036] Such as figure 2 As shown, a heat-not-burn cigarette filter rod 1 includes a tobacco section 2 and a rod section 3. The rod section 3 includes a cooling part 4, a mouth contact part 5, a heat insulation part, etc., and the heat insulation part is Hollow structure, the cooling part 4 includes at least one cavity structure 7, the two ends of the cavity structure 7 have different opening sizes, wherein one end of the large mouth faces the tobacco section, and the end of the small mouth faces the mouth contact part, the cavity of the cooling part 4 The structure 7 is formed by filling the heat-absorbing material in a spiral loose roll shape, and the heat-absorbing material is polylactic acid.

[0037] When the heat-not-burn cigarette filter rod 1 is smoked, the tobacco section 2 is inserted into the corresponding heating device for heating. After the heating is completed, the mouth touch part 5 is smoked, and the smoke flows from the tobacco section 2 into the heat insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com