A kind of spray drying and granulation method and its device

A granulation device and drying technology, applied in the direction of spray evaporation, drying, drying machine, etc., can solve the problems of uneven heating of atomized materials, uneven particles, etc., and achieve rapid and uniform contact, uniform particles, and high contact probability equal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

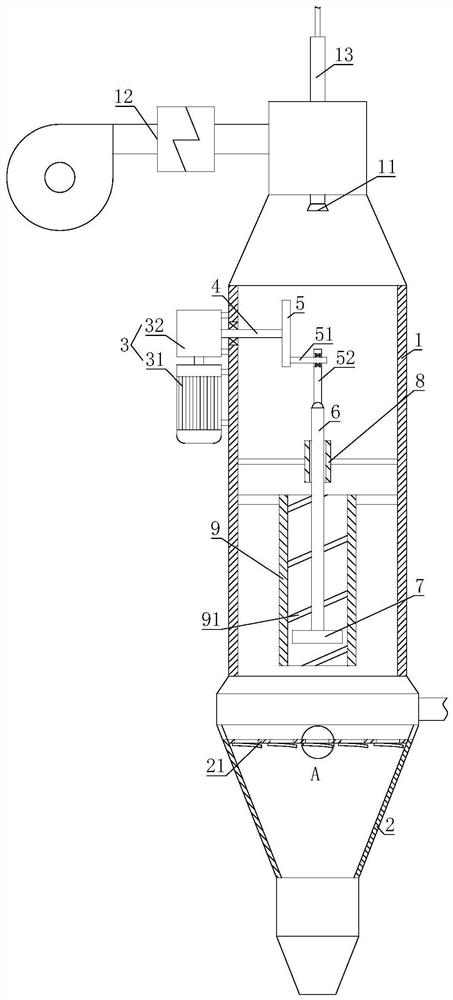

[0029] A spray drying and granulation device, comprising a drying tower 1, the upper end of the drying tower 1 is respectively connected with an atomizing nozzle 11 and a heating and air supply device 12, the atomizing nozzle 11 is connected with a material liquid pipe 13, and the lower end of the drying tower 1 is connected with a Discharge cone 2; the drying tower 1 is equipped with a driving mechanism 3, the output shaft of the driving mechanism 3 is connected with a rotating shaft 4, and the rotating shaft 4 is connected to the side wall of the drying tower 1 through a bearing, and the other end of the rotating shaft 4 is fixed with The turntable 5, the edge of the turntable 5 is fixed with a support rod 51, the other end of the support rod 51 is connected with a connecting rod 52 through a bearing, the other end of the connecting rod 52 is hinged with a lifting rod 6, and the other end of the lifting rod 6 is fixed with a push plate 7 , The push plate 7 is set in the dryin...

Embodiment 2

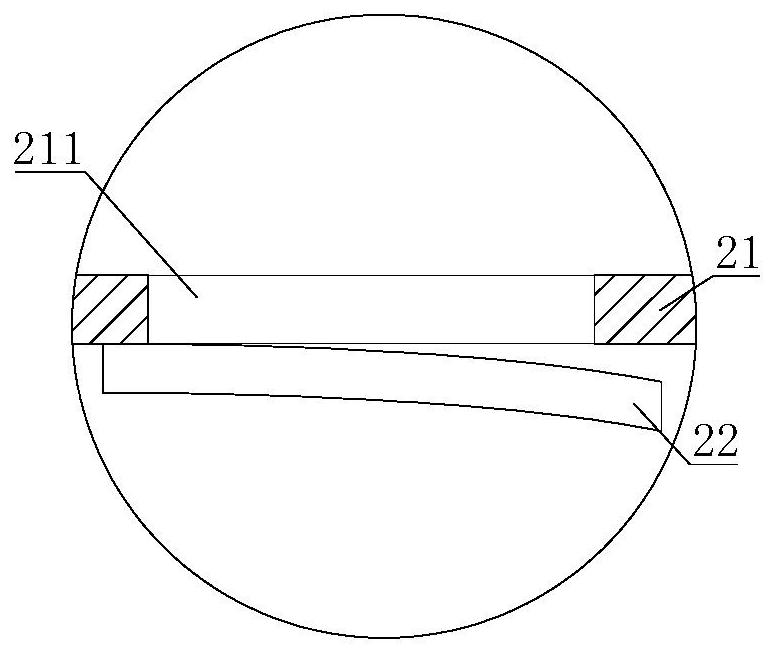

[0032] On the basis of Embodiment 1, a feed plate 21 is fixed inside the discharge cone 2, and a number of feed holes 211 are arranged on the feed plate 21. The lower side of the feed holes 211 is covered with a rubber sheet 22. One end of the sheet 22 is fixed on the feed plate 21 .

[0033] When the air flow goes down, the rubber sheet 22 at the feed hole 211 is pushed away, and the particles can fall into the discharge cone 2 from the feed hole 211 . And when the airflow is upward, the rubber sheet 22 will be close to the feed plate 21 under the action of the airflow, and the feed hole 211 will be closed, so as to avoid the situation that the particles in the discharge cone 2 are brought into the drying tower 1 again, and ensure the accurate collection of the particles.

Embodiment 3

[0035] On the basis of embodiment one or embodiment two, described driving mechanism 3 comprises motor 31, and the output shaft of motor 31 is connected with speed reducer 32, and motor 31 and speed reducer 32 are all installed on the drying tower 1, and the speed reducer 32 Output shaft and rotating shaft 4 are fixed.

[0036] After the motor 31 is started, the motor 31 drives the reducer 32 to act, and the reducer 32 can drive the rotating shaft 4 to rotate, so that the turntable 5 rotates accordingly. Driven by the drive mechanism 3, the push plate 7 can move back and forth continuously, and the atomized material in the drying tower 1 can be fully and uniformly mixed with the heating air, ensuring that the atomized material is evenly heated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com