Simple unpowered stirring device

A stirring device, a simple technology, applied in the field of sewage treatment equipment, can solve the problems of high cost and inapplicability, and achieve the effect of reducing the cost of manufacturing and using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

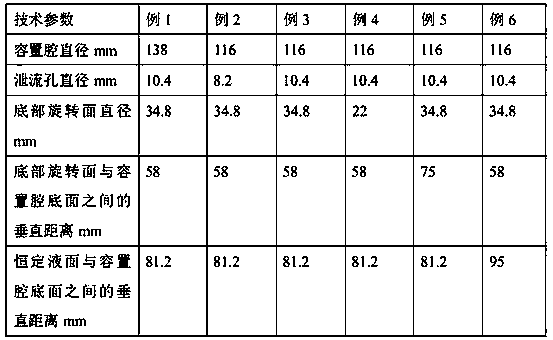

[0019] In this embodiment, the diameter of the accommodating chamber 11 is 138 millimeters, the diameter of the discharge hole 12 is 10.4 millimeters, the diameter of the bottom rotating surface 21 of the agitator 2 is 34.8 millimeters, the bottom rotating surface 21 of the agitator 2 is in contact with the accommodation The vertical distance between the bottom surfaces of the chambers 11 is 58 mm. When the accommodating chamber 11 is filled with liquid, a constant liquid level 3 is formed. The vertical distance between the constant liquid level 3 and the bottom surfaces of the accommodating chambers 11 is 81.2 mm. Using this technology The simple non-powered stirring device made of parameter specifications, in the actual experimental use, the specification of the accommodating chamber 11 is too large, carrying more liquid, the diameter of the discharge hole 12 is not set to form a vortex with sufficient force, and the liquid The flow velocity is relatively slow, and the stirri...

Embodiment 2

[0021] In this embodiment, the diameter of the accommodating chamber 11 is 116 millimeters, the diameter of the discharge hole 12 is 8.2 millimeters, the diameter of the bottom rotating surface 21 of the agitator 2 is 34.8 millimeters, the bottom rotating surface 21 of the agitator 2 is compatible with the accommodation The vertical distance between the bottom surfaces of the chambers 11 is 58 mm. When the accommodating chamber 11 is filled with liquid, a constant liquid level 3 is formed. The vertical distance between the constant liquid level 3 and the bottom surfaces of the accommodating chambers 11 is 81.2 mm. Using this technology The simple non-powered stirring device made according to the parameter specifications, in the actual experimental use, the diameter of the discharge hole 12 is not set to form a vortex with sufficient force, the liquid flow rate is relatively slow, and the stirring effect of the stirrer 2 is not obvious. The simple non-powered stirring device und...

Embodiment 3

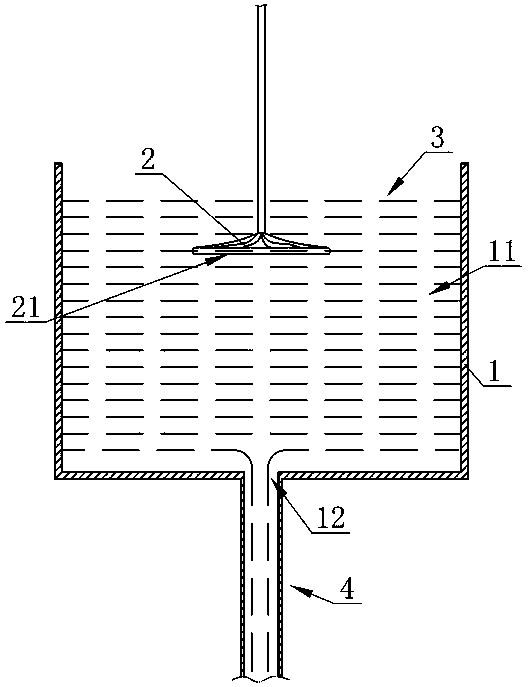

[0023] Such as figure 1 As shown, a simple unpowered stirring device, in the present embodiment, the diameter of the accommodation cavity 11 is 116 mm, the diameter of the discharge hole 12 is 10.4 mm, and the diameter of the bottom rotating surface 21 of the agitator 2 is 34.8 mm , the vertical distance between the bottom rotating surface 21 of the agitator 2 and the bottom surface of the accommodating cavity 11 is 58 millimeters. When the accommodating cavity 11 is filled with liquid, a constant liquid level 3 is formed, and the constant liquid level 3 and the bottom surface of the accommodating cavity 11 The vertical distance between them is 81.2 mm. The simple unpowered stirring device made by using this technical parameter specification, in actual experimental use, the diameter of the discharge hole 12 is set so that the force of the formed vortex is enough to drive the rapid flow of the whole liquid , is enough to drive the agitator 2 to rotate, but the rotation speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com