Mobile mortar production equipment for building and production method thereof

A technology for production equipment and construction, which is applied to mobile mortar production equipment for construction and its production field, can solve problems such as uneven mixing, poor mixing effect, and impact on production quality, and achieves improved practicability, reduced resistance, and improved reliability. and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

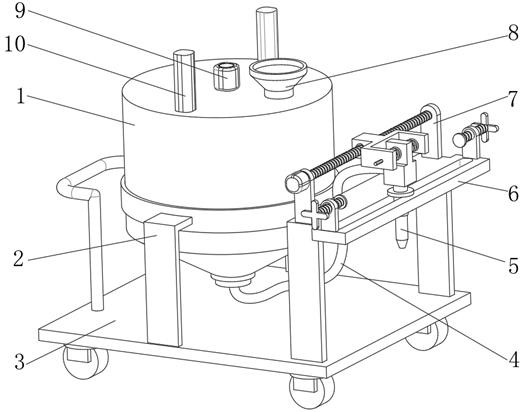

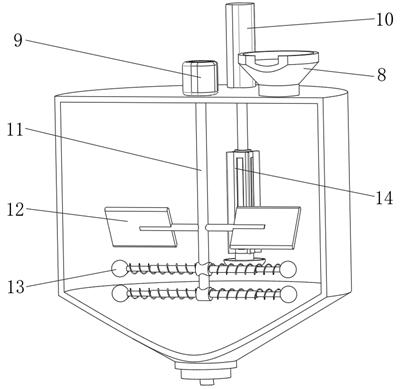

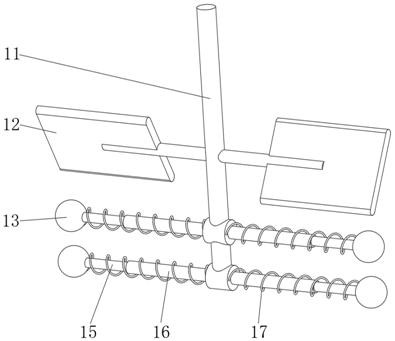

[0037] A mobile mortar production equipment for construction, such as Figure 1-5 As shown, it includes a stirring tank 1 and a car body 3, the top of the stirring tank 1 is welded with a feed hopper 8, the stirring tank 1 is installed on the outer wall of the top of the car body 3 through the mounting seat 2, and the outer wall of the top of the stirring tank 1 is fixed by screws There are two symmetrical electric telescopic rods 10, the output ends of the two electric telescopic rods 10 are rotatably connected to a rotating seat 22, and the outer wall of the rotating seat 22 is rotatably connected to a lifting frame 14, and the outer wall of the lifting frame 14 is provided with evenly distributed rectangular passages 18 , the outer wall of the bottom end of the lifting frame 14 is fixed with a bowl-shaped seat 19 by screws; a stirring mechanism is arranged between the two lifting frames 14, and the stirring mechanism includes a stirring main shaft 11 and more than two stirri...

Embodiment 2

[0046] A production method of the mobile mortar production equipment described in embodiment 1, such as Figure 1-5 shown, including the following steps:

[0047] S1: Weighing mortar raw materials;

[0048] S2: Add the mortar raw material into the mixing tank 1 through the feed hopper 8;

[0049] S3: Control the stirring motor 9 to rotate and stir the mortar;

[0050] S4: Control the electric telescopic rod 10 to work to vertically stir the mortar;

[0051] S5: After the stirring is completed, the stirring motor 9 and the electric telescopic rod 10 are stopped, and the mortar is output through the pump body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com