A raw material impurity removal and screening device for grain and oil processing

A technology of impurity removal and screening device, applied in the direction of sieve, separation of solid from solid by air flow, solid separation, etc. It can solve the problems of harsh working environment, pollute the environment, affect equipment wages, etc., and achieve good screening effect. , The effect of less floating matter impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

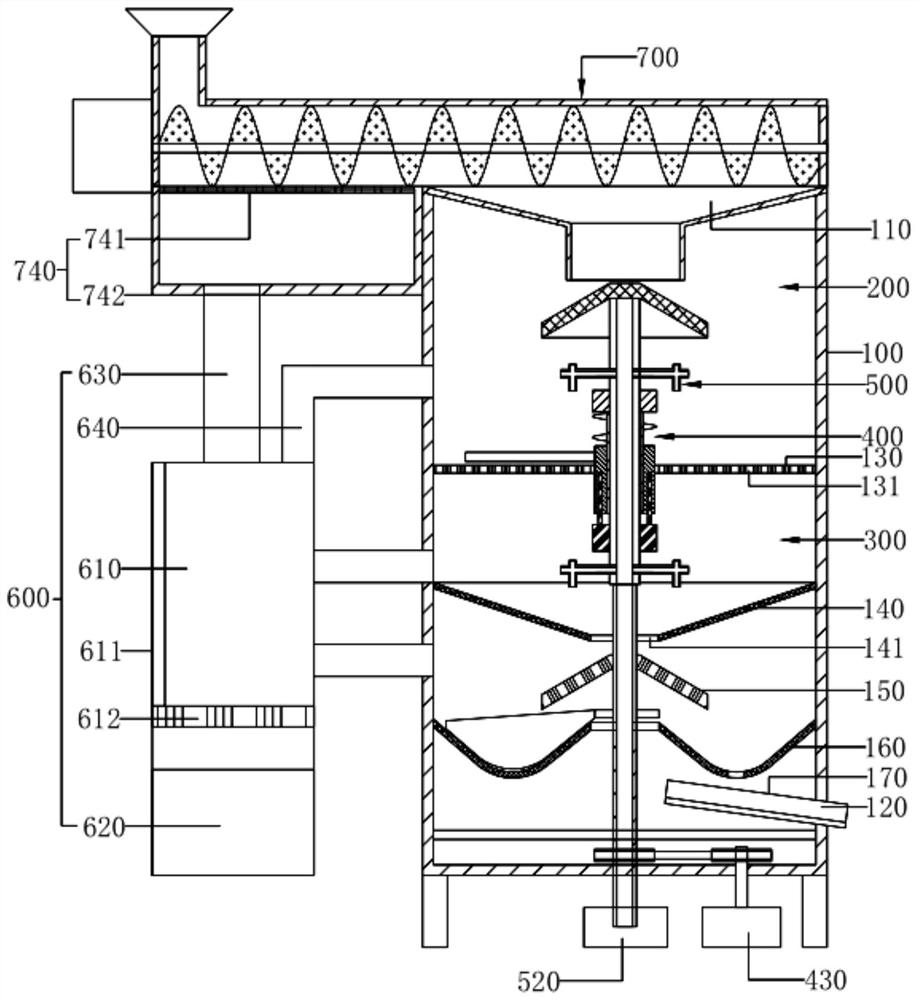

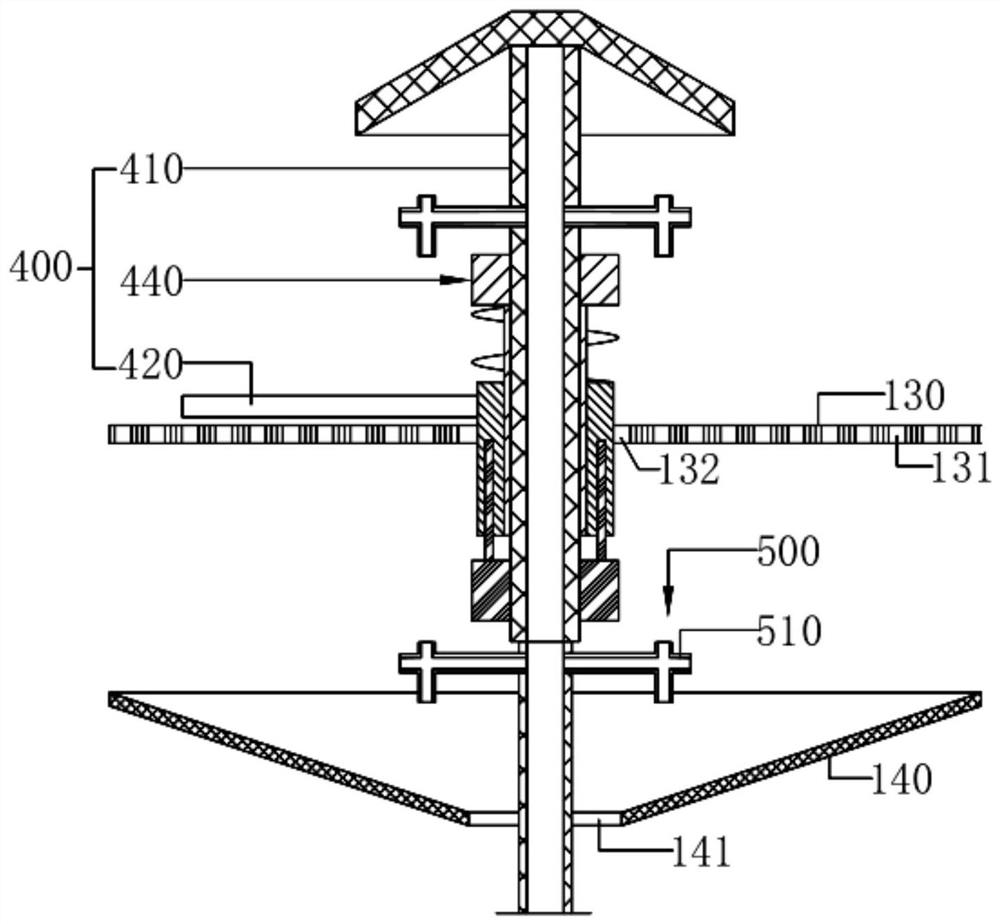

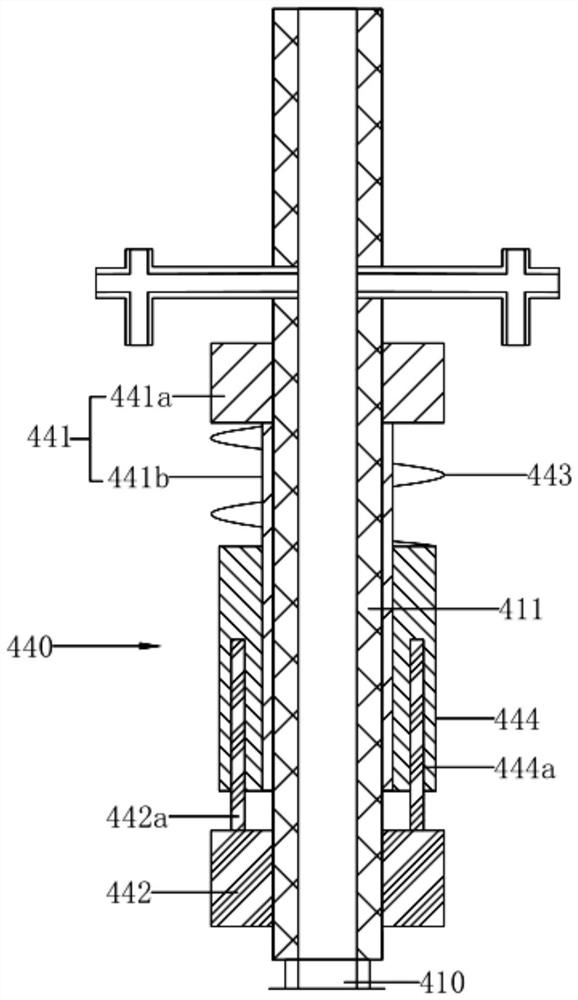

[0034] The invention provides a raw material impurity removal and screening device for grain and oil processing, see Figure 1-Figure 5 , including a box body 100, a material inlet 110 is opened on the upper side of the box body 100, and a material outlet 120 is arranged on the lower side, and the floating impurities contained in the raw material are removed inside the box body 100. Specifically, a first partition 130 and a second partition 140 are fixed inside the box body 100, wherein the first partition 130 is close to the side of the feed inlet 110, and the second partition 140 is located on a side far away from the feed inlet 110. side, the box body 100 is divided by the isolation effect of the first partition 130 and the second partition 140, and the first impurity removal chamber 200 is formed on the upper side of the first partition 130, and the first partition 130 and the second partition A second impurity removal chamber 300 is formed between the plates 140 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com