Cooling liquid blowing device for testing automobile battery assembly

A technology for automobile batteries and coolants, which is applied in household refrigeration devices, cooling fluid circulation devices, measuring devices, etc., can solve problems such as unstable air pressure, increased air pressure in storage tanks, and easy obstruction of cooling liquid return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

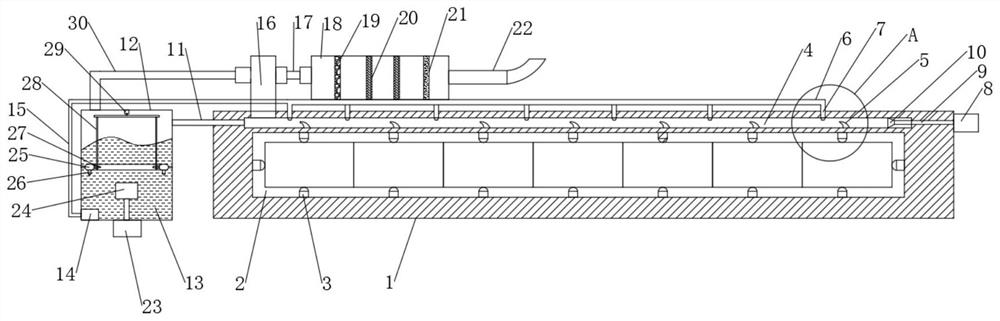

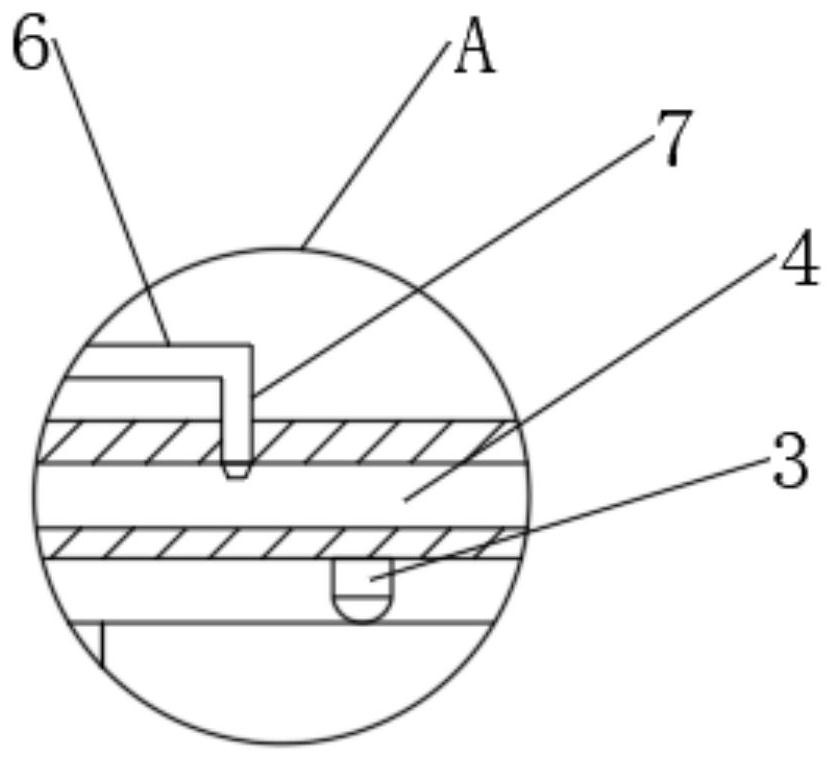

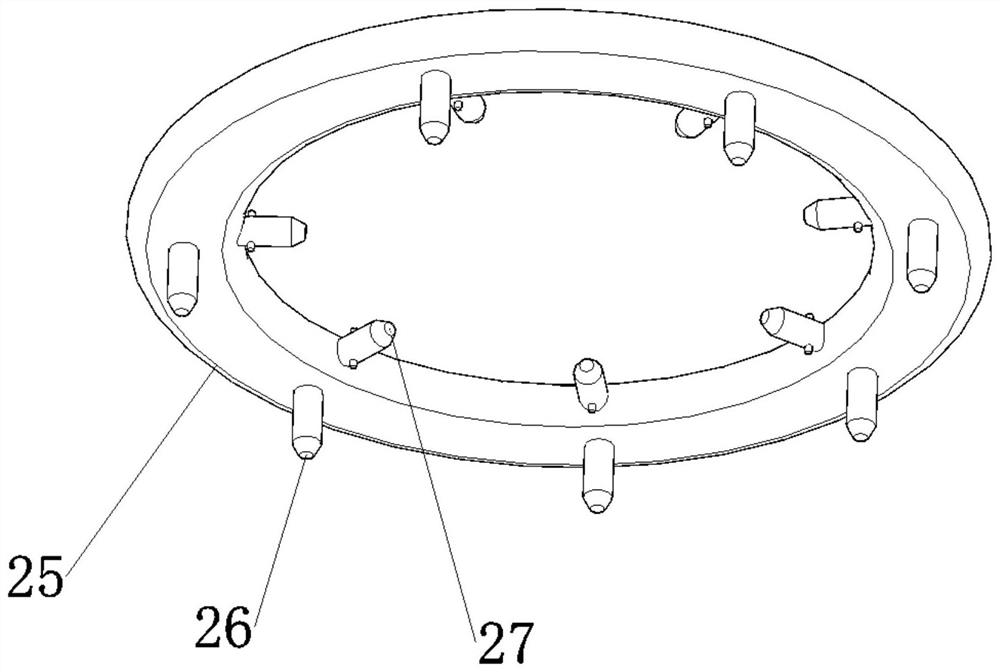

[0024] Such as Figure 1-3 As shown, a cooling liquid purging device for automobile battery assembly test includes a mounting shell 1, a mounting groove 2 is arranged in the mounting shell 1, batteries are uniformly arranged in the mounting groove 2, and the mounting groove 2 The top of the cooling tank 4 is provided with a cooling tank 4, and the cooling tank 4 is horizontally attached to the upper side of the installation tank 2. The blocking block 5 is evenly arranged in the cooling tank 4, and the fan 8 is provided on the side of the cooling tank 4. The fan 8 is connected to the air guide pipe 9, the end of the cooling tank 4 is provided with an air outlet 10, the air outlet 10 is connected to the air guide pipe 9, the blocking block 5 is arranged inclined to the left, and the cooling The left side of the tank 4 is provided with a pressure-stabilizing cylinder 16, and the left end of the cooling tank 4 is horizontally connected with a return pipe 11, and the return pipe 11...

Embodiment 2

[0035] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

[0036] A coolant purging device for automotive battery assembly testing, comprising a mounting case 1, a mounting groove 2 is arranged in the mounting case 1, batteries are evenly arranged in the mounting groove 2, and the top of the mounting groove 2 is arranged There is a cooling groove 4, and the cooling groove 4 is horizontally attached to the upper side of the installation groove 2, and a blocking block 5 is uniformly arranged in the cooling groove 4, and a fan 8 is arranged on the side of the cooling groove 4, and the fan 8 8 is connected with the air guide pipe 9, and the end of the cooling tank 4 is provided with an air outlet 10, and the air outlet 10 is connected with the air guide pipe 9, and the blocking block 5 is arranged inclined to the left, and the cooling tank 4 The left side is provided with a pressure stabilizing cylinder 16, and the left end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com