Testing device for simulating flow field in continuous casting crystallizer

A continuous casting crystallizer and test device technology, applied in the direction of instruments, teaching models, educational tools, etc., can solve the problem that the mold inner cavity width cannot be adjusted online, the crystallizer flow field cannot be measured, and the mold billet shell taper cannot be simulated and the thickness of the slab solidified layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

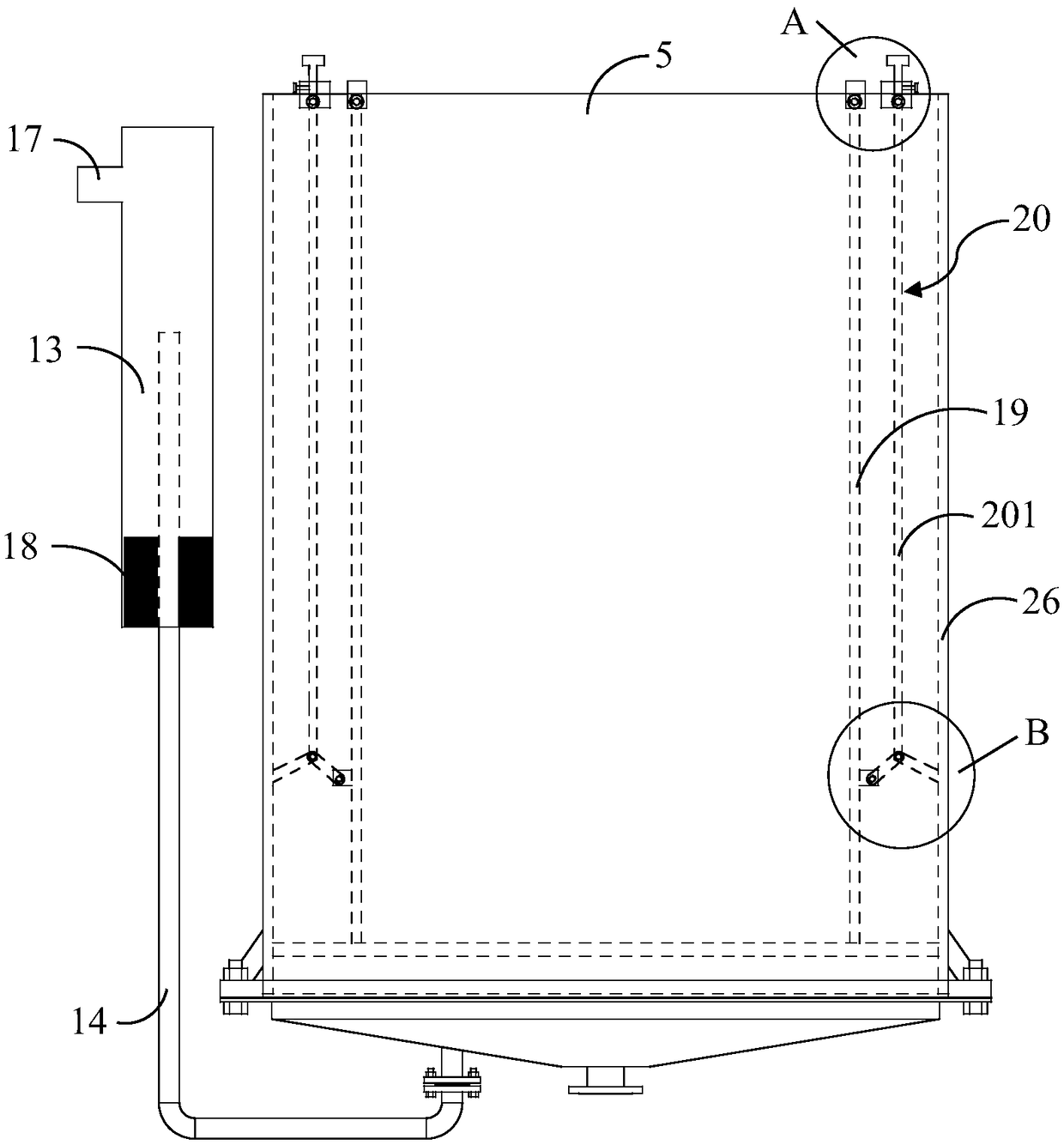

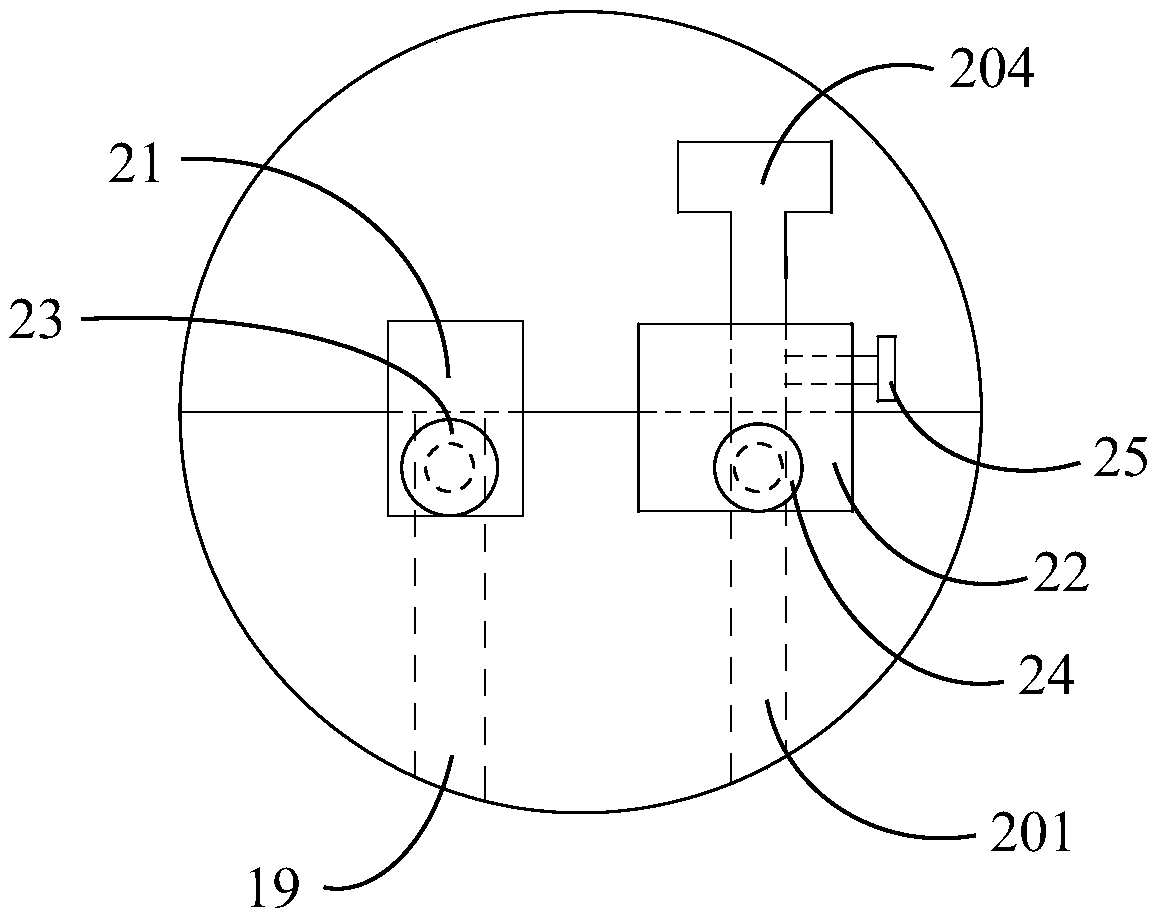

[0034] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

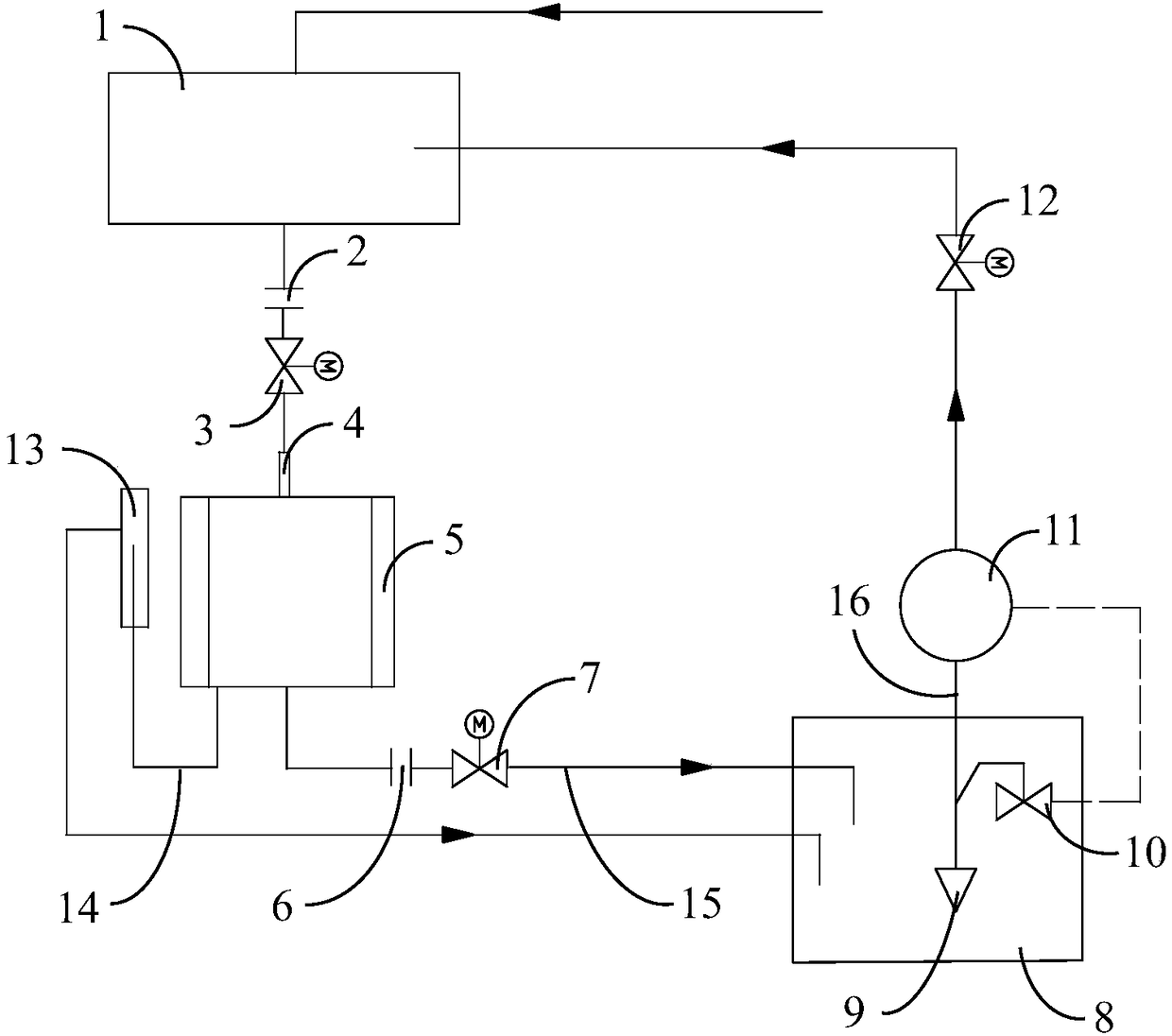

[0035] see figure 1 , the test device for simulating the flow field in the continuous casting mold of the present invention includes a water tank 1 , a mold model 5 and a return pool 8 .

[0036] The water tank 1 is provided with an industrial water inlet (not shown in the figure), through which the industrial water enters the water tank 1 as a medium for simulating the crystallizer flow field.

[0037] The crystallizer model 5 can be a cuboid structure made of plexiglass. The top of the crystallizer model 5 is inserted with a submerged nozzle 4. The upper part of the submerged nozzle 4 communicates with the water tank 1. Between the water tank 1 and the submerged nozzle 4 A first flow regulating valve 3 for regulating the inlet flow of the crystallizer model 5 is arranged between them.

[0038] The backwater pool 8 is respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com