Mobile sandblasting robot control system

A control system and robot technology, applied in spray guns, manufacturing tools, used abrasive processing devices, etc., can solve the problems of high pollution, low work efficiency, and health damage in sandblasting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

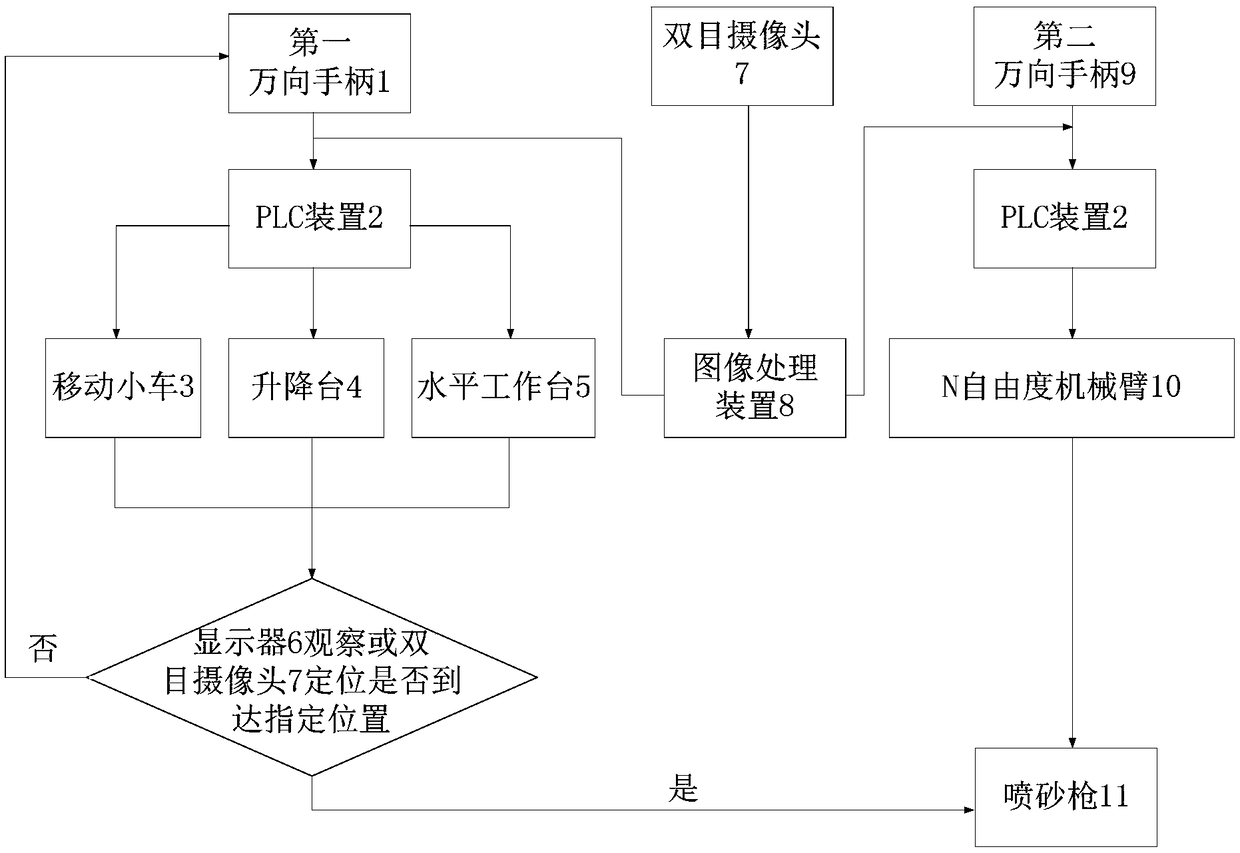

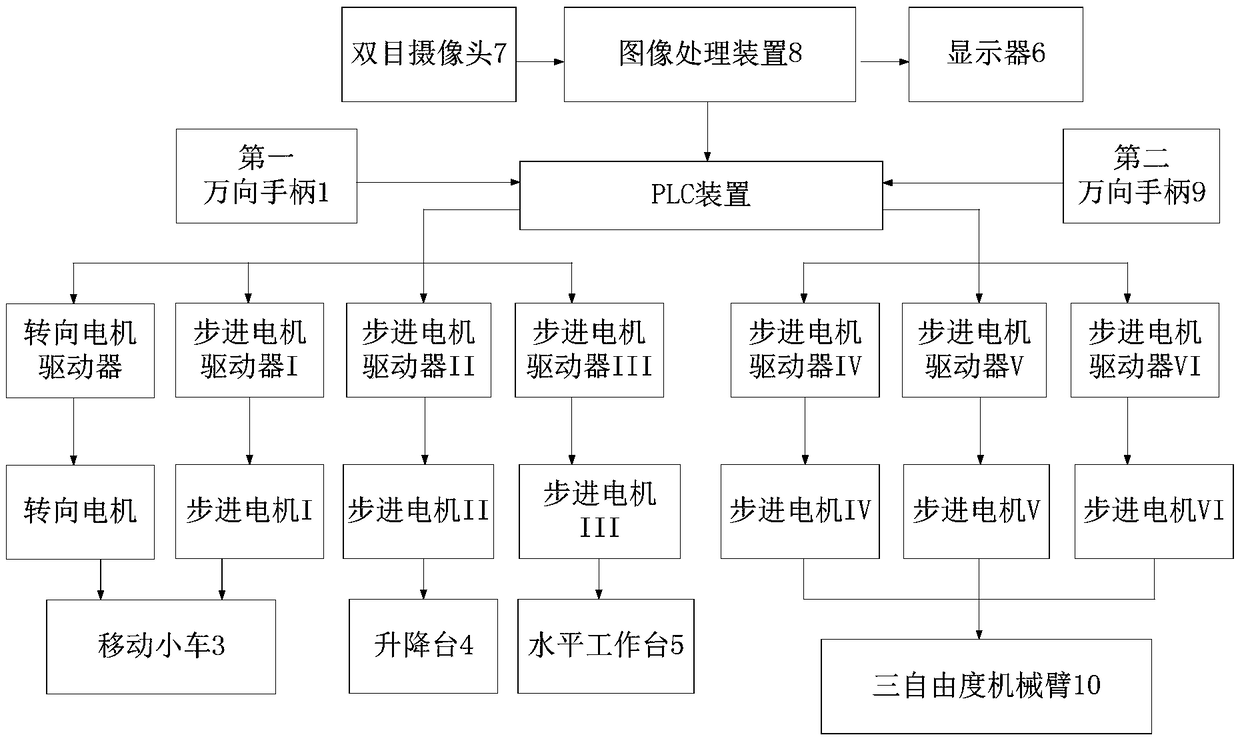

[0027] like figure 1 and figure 2 As shown, the mobile sandblasting robot control system includes:

[0028] Mobile dolly 3 is provided with a stepper motor 1 and a stepper motor driver 1 for driving the front wheels, and a steering motor and a steering motor driver for driving the rear wheels; wherein, the output shaft of the stepper motor 1 is connected to the front wheel Connect by shaft coupling, stepper motor driver 1 is connected with stepper motor 1, control the rotational speed (being the speed of travel of moving dolly 3) of stepper motor 1 output shaft, direction of rotation (being that the direction of travel of moving dolly 3 is forward or back) and the number of rotations (i.e. the travel distance of the mobile trolley 3); the output shaft of the steering motor is connected with the steering mechanism arranged on the rear wheel of the trolley through a coupling, and the steering motor driver is connected with the steering motor to control the rotation of the stee...

Embodiment 2

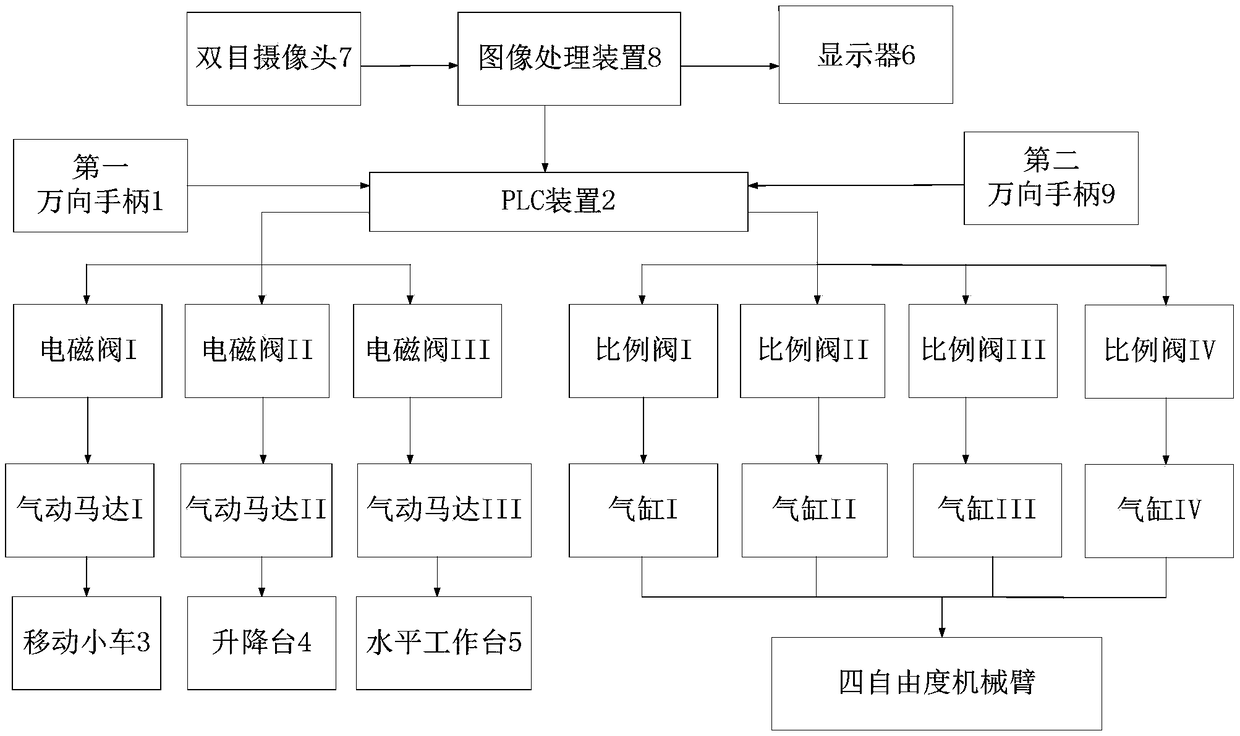

[0038] like figure 1 and image 3 As shown, the mobile sandblasting robot control system includes:

[0039] The mobile trolley 3 is provided with an air motor I and an electromagnetic valve I for driving the wheels; the output shaft of the air motor I is connected with the active wheel group of the trolley through a coupling, and the solenoid valve I is connected with the air motor I to control the air motor I The rotation speed of the output shaft (that is, the traveling speed of the trolley), the direction of rotation (that is, the traveling direction of the trolley) and the number of rotations (that is, the traveling distance of the trolley);

[0040] The lifting platform 4 is provided with an air motor II and a solenoid valve II that drive the lifting platform 4 to move up and down; the output shaft of the air motor II is connected to the nut screw of the lifting platform 4 through a coupling, and the solenoid valve II and the air motor II Connect to control the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com