Viscose filament spooling equipment oil feeding device

A viscose and equipment technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of affecting product quality, unfavorable reproduction, high production cost, etc., to reduce labor intensity of workers and improve winding Efficiency and joint time saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

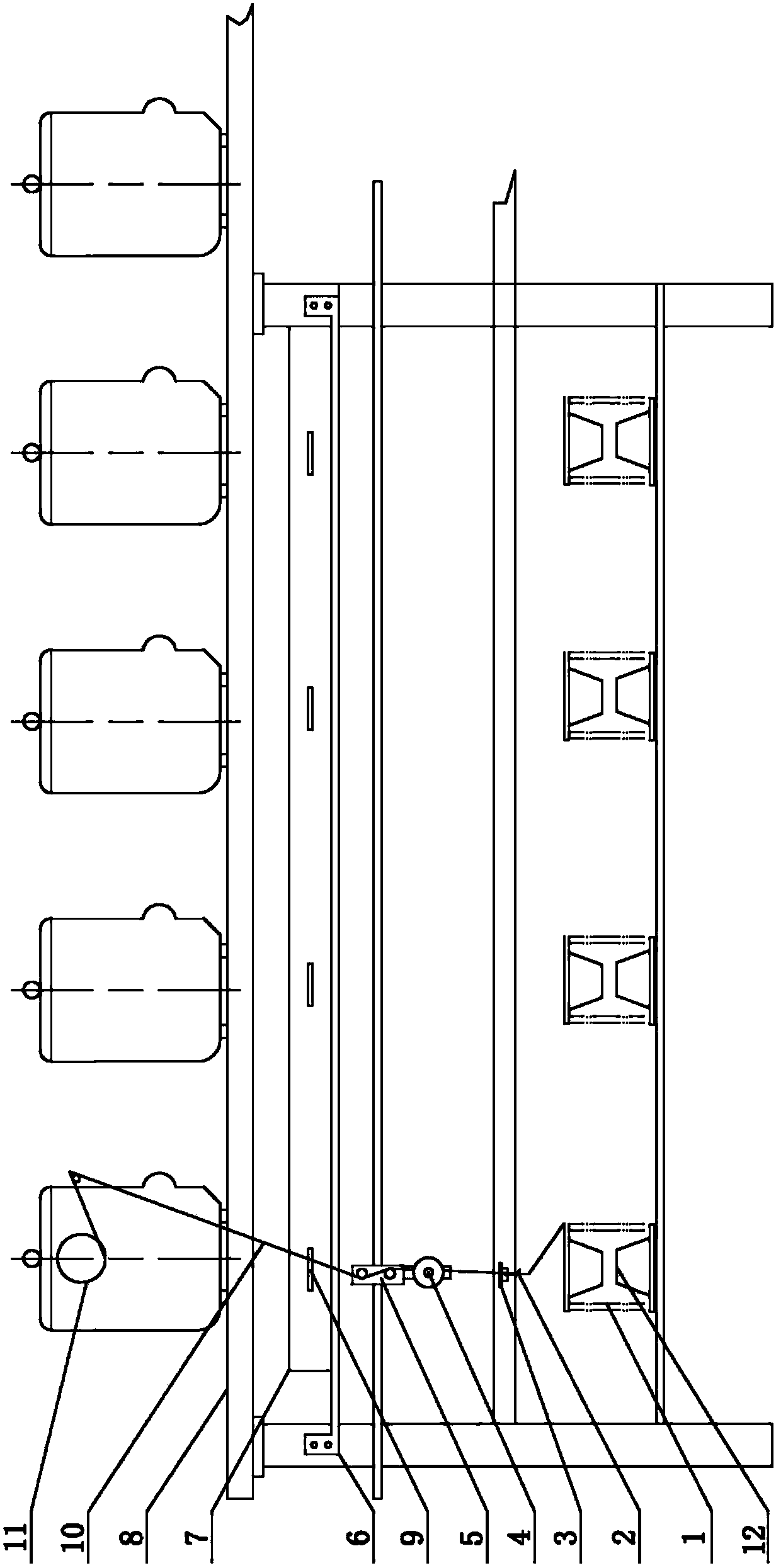

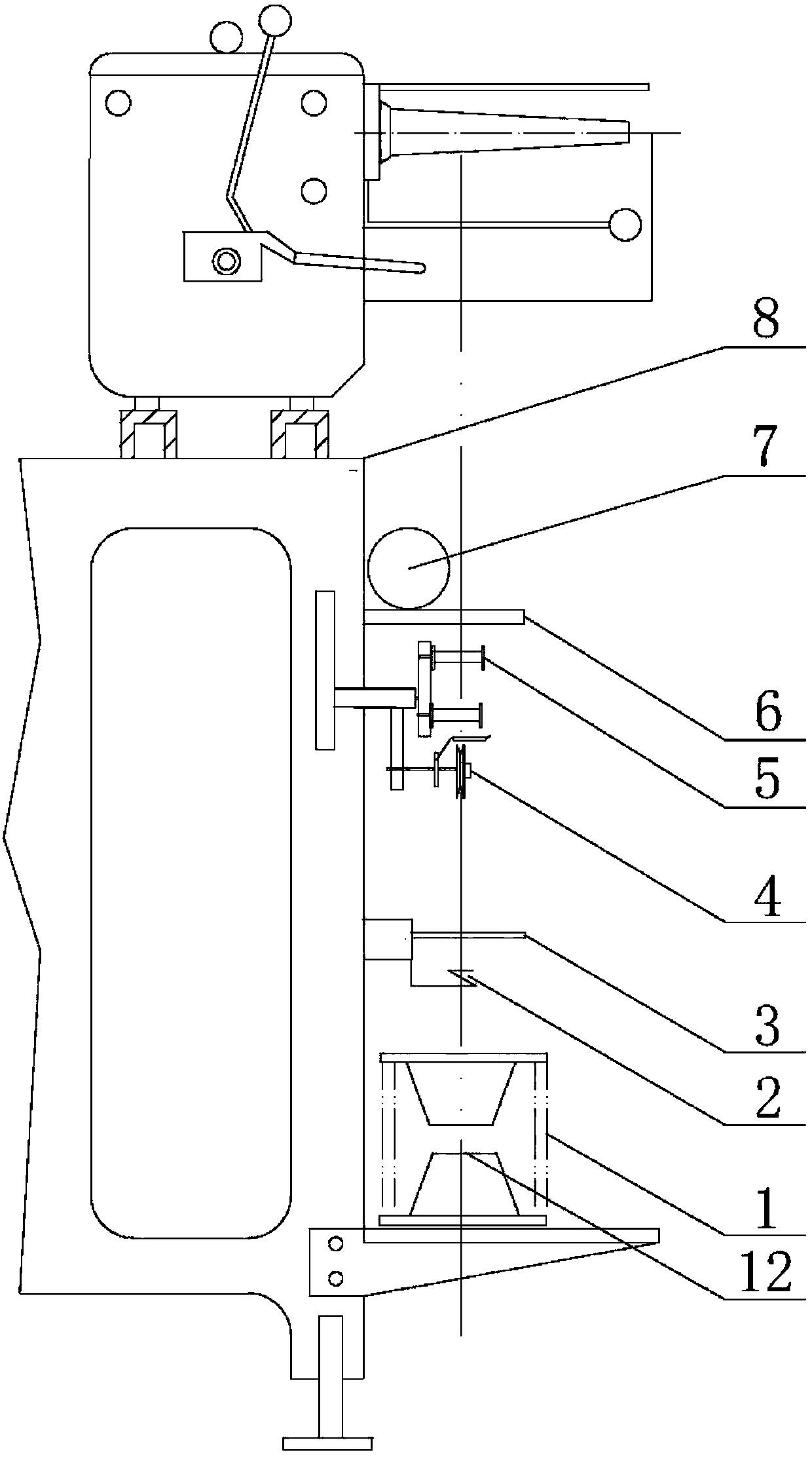

[0031] The viscose filament winding equipment oiling device of the present invention is described in detail below in conjunction with the accompanying drawings:

[0032] Such as figure 1 and figure 2 As shown, the viscose filament winding equipment oiling device of the present invention, the viscose filament cake 1 is arranged on the viscose filament winding equipment, the described oiling device is arranged on the winding equipment, and is located in the viscose The upper part of the filament cake 1 includes an oiling pipe 7 and an oil-absorbing medium. An oiling port 9 is provided on the oiling pipe 7. One end of the oil-absorbing medium is immersed in the oiling pipe 7 through the oiling port 9, and the other end is connected with the viscose filament. The strands 10 of the cake 1 are in contact.

[0033] Winding equipment is a special equipment for the textile industry. As the last process of spinning and the first process of weaving, winding plays the role of "bridge"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com