Preparation method and application of micron iron phosphate with different shapes

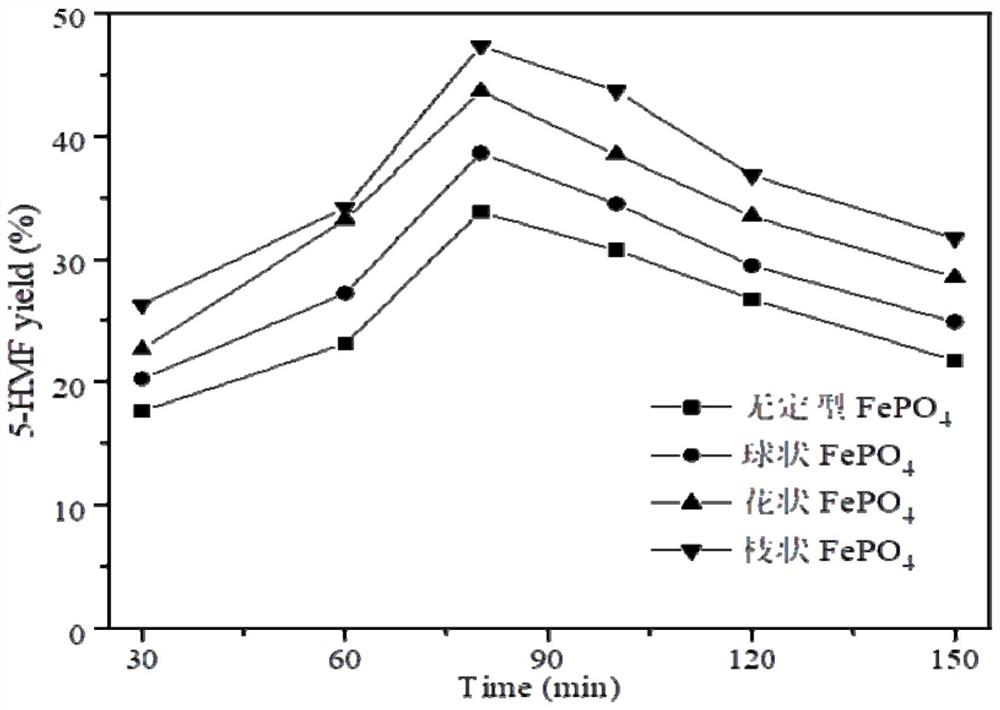

A technology of iron phosphate and morphology, applied in chemical instruments and methods, phosphorus compounds, organic chemistry, etc., can solve problems such as high energy consumption, low output rate, and restrictions on the production and application of 5-hydroxymethylfurfural, and achieve catalytic Excellent performance and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

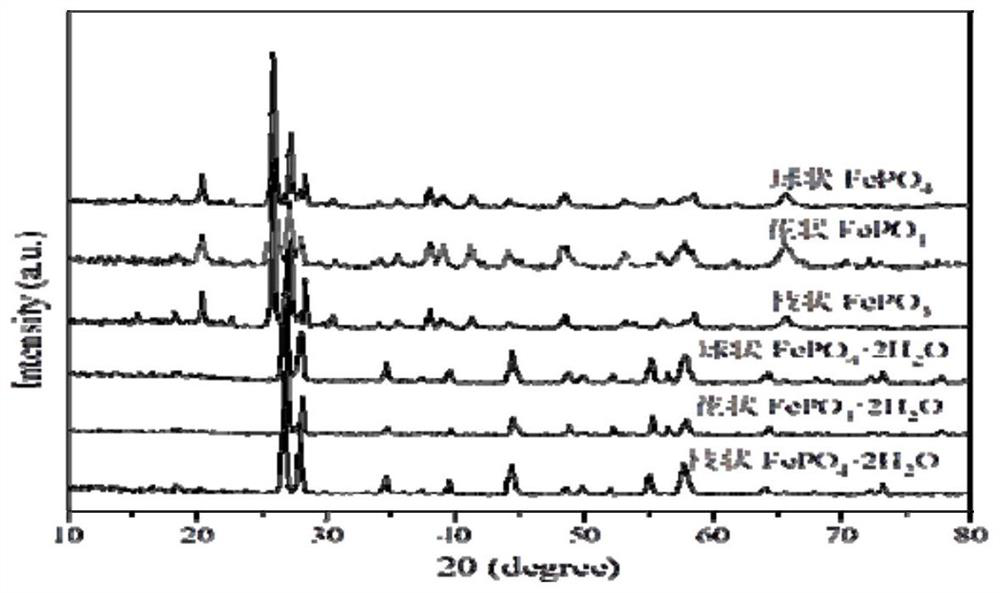

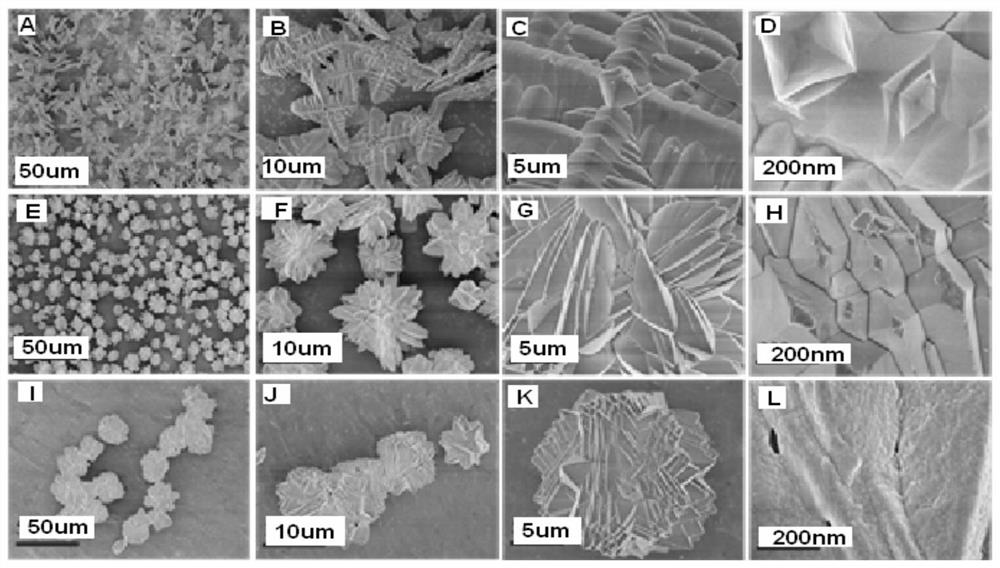

[0025] Weigh 0.4g of ferric nitrate nonahydrate, 0.3g of sodium dihydrogen phosphate and 2.0g of polyvinylpyrrolidone (Mw=3000000) into 100ml of 50% ethanol aqueous solution, after ultrasonic dispersion at a temperature of 25°C and a stirring speed of 320r / min Stir at constant temperature for 60 min to form a uniform mixed solution. Put the solution into a hydrothermal kettle and react at 180°C for 10 h. After natural cooling, remove the supernatant and wash twice with deionized water and ethanol to obtain FePO 4 2H 2 O. Dry in a vacuum oven at 80°C for 7h, and then bake at 550°C in a muffle furnace for 2h to obtain dendritic iron phosphate FePO 4 .

Embodiment 2

[0027] Weigh 0.5g of ferric nitrate nonahydrate, 0.4g of sodium dihydrogen phosphate and 2.0g of polyethylene glycol (Mw=20000) into 150ml of 50% ethanol aqueous solution, after ultrasonic dispersion at a temperature of 25°C and a stirring speed of 400r / min Stir at constant temperature for 60 min to form a uniform mixed solution. Put the solution into a hydrothermal kettle and react at 100°C for 16 hours. After natural cooling, remove the supernatant and wash twice with deionized water and ethanol to obtain FePO 4 2H 2 O. After drying in a vacuum oven at 50°C for 5h, and then roasting in a muffle furnace at 500°C for 2h, dendritic iron phosphate FePO 4 .

Embodiment 3

[0029] Weigh 0.8g of ferric nitrate nonahydrate, 0.3g of sodium dihydrogen phosphate and 2.0g of polyvinylpyrrolidone (Mw=3000000) into 100ml of 50% ethanol aqueous solution, and ultrasonically disperse them at a temperature of 25°C and a stirring speed of 300r / min. Stir at constant temperature for 60 min to form a uniform mixed solution. Put the solution into a hydrothermal kettle and react at 150°C for 12 hours. After natural cooling, remove the supernatant and wash twice with deionized water and ethanol to obtain FePO 4 2H 2 O. After drying in a vacuum oven at 60°C for 10h, it was then fired in a muffle furnace at 520°C for 2h to obtain flower-shaped iron phosphate FePO 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com