Treatment system and treatment method for high-temperature titanium tetrachloride dusty gases

A gas treatment system and technology of titanium tetrachloride, applied in the direction of titanium tetrachloride, titanium halide, lighting and heating equipment, etc., can solve the problems of fouling of condensing system equipment, unreasonable energy saving and consumption reduction, thinning, etc. Investment saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

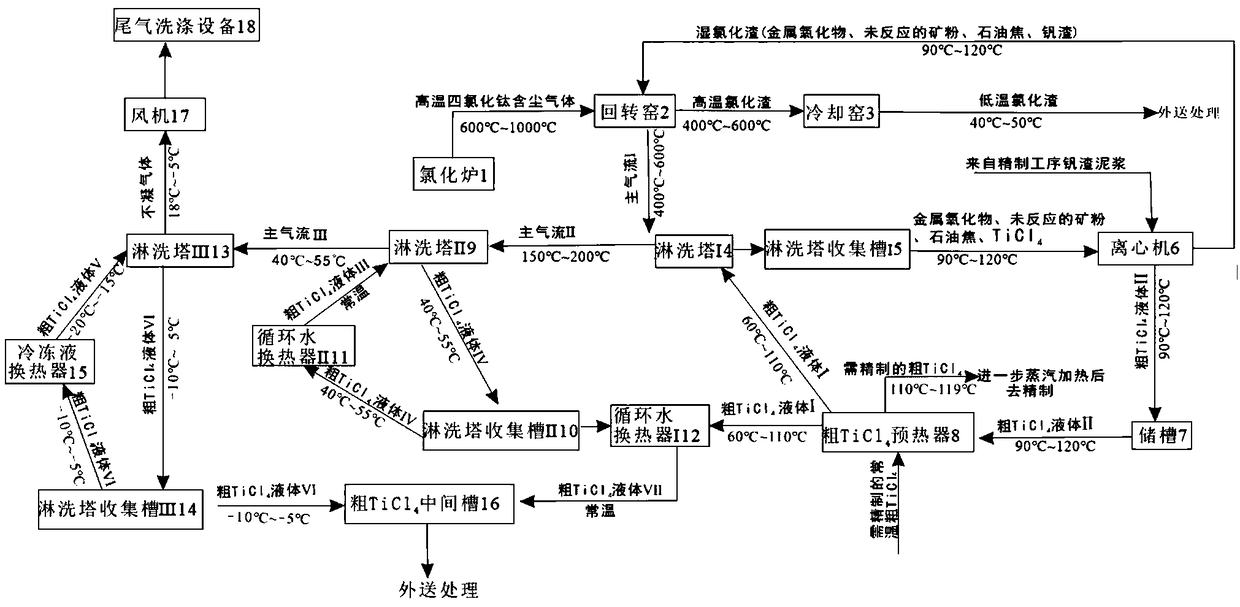

[0057] Such as figure 1 Shown is the process flow diagram of the present invention, and the high-temperature titanium tetrachloride dust-containing gas treatment system of the present invention is described in conjunction with specific embodiments, which is used to realize the treatment of high-temperature titanium tetrachloride dust-containing gas of a specific embodiment of the present invention The system specifically includes: chlorination furnace 1, rotary kiln 2, cooling kiln 3, leaching tower Ⅰ4, leaching tower Ⅱ9 and leaching tower Ⅲ13, leaching tower collecting tank Ⅰ5 wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap