In-situ synthesized TiB2 particle-reinforced Al matrix composite and preparation method thereof

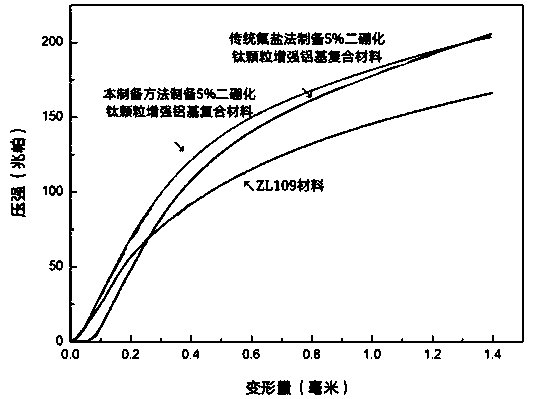

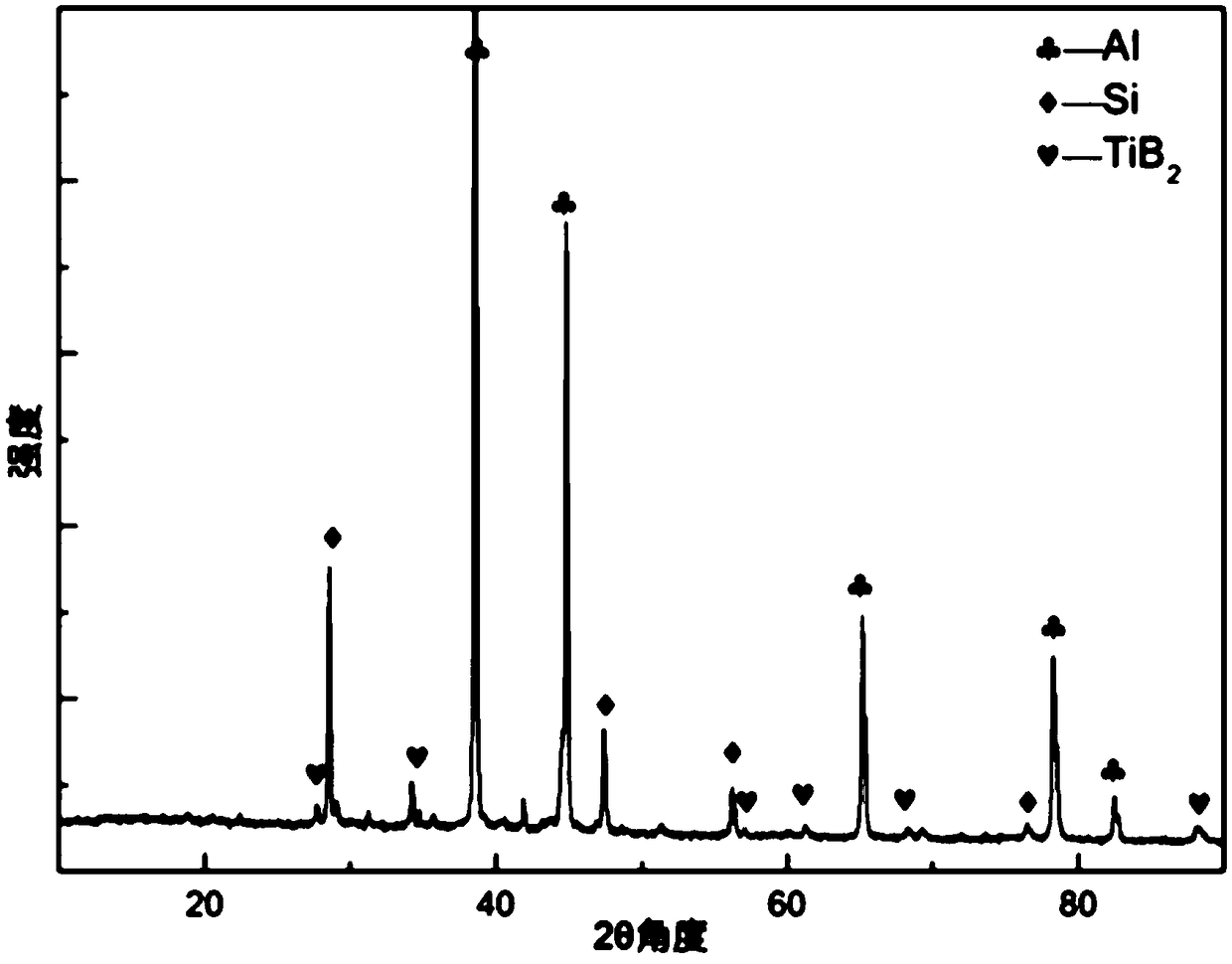

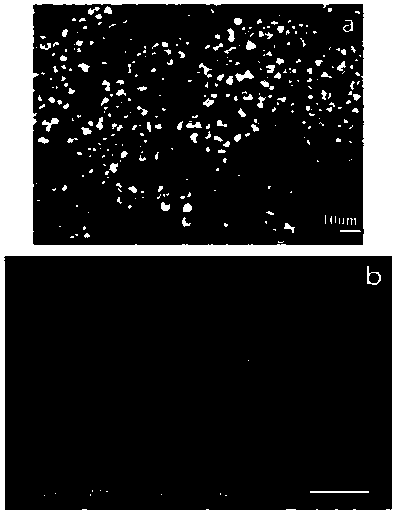

A composite material and in-situ generation technology, which is applied in the field of composite materials, can solve problems such as uneven distribution and large particles, and achieve the effect of uniform distribution, small particle size and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] In situ self-generated TiB 2 Preparation method of particle reinforced aluminum matrix composite material:

[0075](1) Put 250g ZL109 polished on the surface into a drying oven at 100°C, and dry it for 2 hours to remove moisture; add ZL109 aluminum alloy to a crucible preheated at 650°C, and put it in an electromagnetic induction furnace to heat up to 850°C to ZL109 melt into a melt.

[0076] (2) weighed 86.35g of K 2 TiF 6 The powder (analytical pure, produced by Guangdong Wengjiang Chemical Reagent Co., Ltd.) was placed in a drying box at 100 °C for 2 hours to fully remove the moisture of the powder. At the same time, a graphite stirring rod was used to stir the ZL109 melt at 600 r / min and a melt vortex was formed. 2 TiF 6 The powder was added to the melt vortex to make the fluoride salt fully react in the melt, and the stirring rod was stirred for 10 minutes. After the stirring was completed, the ZL109 melt was allowed to stand for 30 minutes.

[0077] (3) Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com