Processing method and device for wrapping composite mixed-segment-colored filament yarn and filament yarn

A processing method and technology of filament yarn, which is applied in yarn, textile and papermaking, etc., can solve the problem that the color variety of chemical fiber filament yarn needs to be expanded, and achieve the effect of expanding the design range, simple segment color control technology, and increasing the color variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

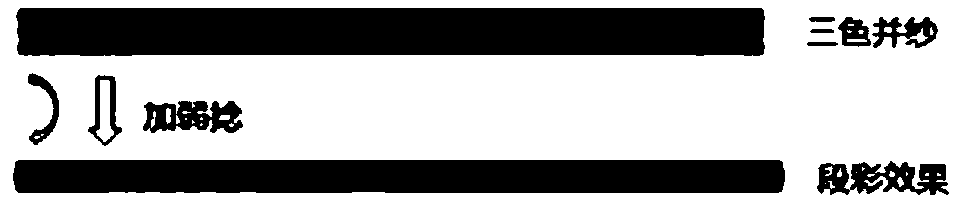

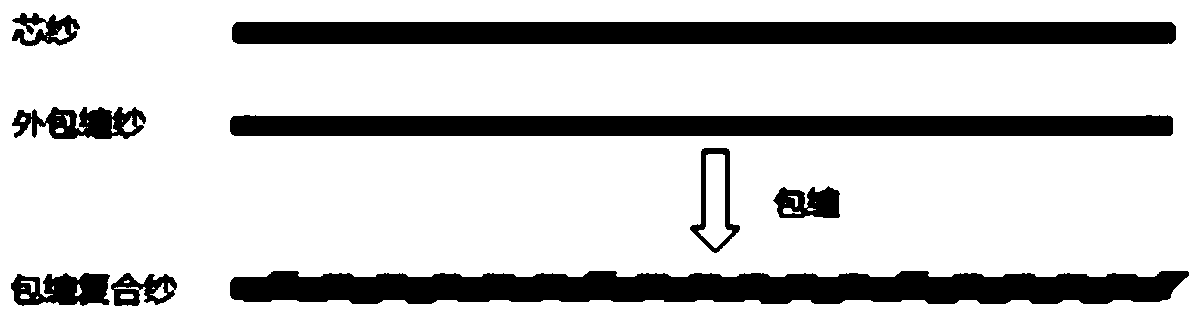

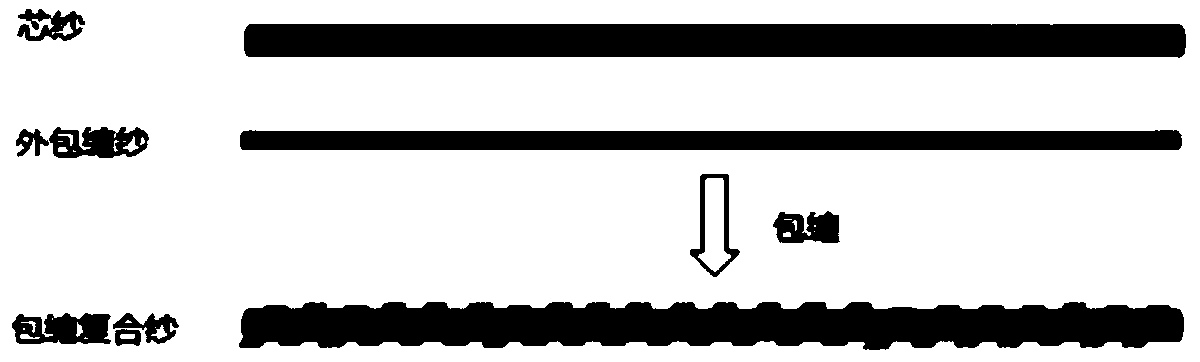

Method used

Image

Examples

Embodiment 1

[0103] Specifications of core yarn and wrapping yarn: polyester DTY air network yarn 167dtex / 36F, network node 140 / m.

[0104] Core yarn color: core yarn 1 color, red; core yarn 2 color, blue.

[0105] Outer wrapping yarn color: Red, blue and beige are used to wrap the double core yarn respectively.

[0106] The hollow spindle speed is 15435r / min, the yarn drawing speed is 35m / min, the wrapping twist is 441 twists / m, and the wrapping twist is S twist.

[0107] The eccentric distance of the rendezvous yarn guide hook is 2mm.

[0108] Its effect is as Figure 11 shown. The color of the wrapping yarn is the determining factor of the overall color of the wrapping yarn. Changing the color of the wrapping yarn will result in a huge difference in the overall color of the finished yarn. The colors of the outer wrapping yarns are different, and the colors of the yarn segments are different. When the color of the outer wrapping yarns is the same as that of one of the core yarns, the...

Embodiment 2

[0112] The specifications of core yarn and wrapping yarn are nylon 6 DTY, 70D / 24F.

[0113] The core yarn is red, yellow, and blue in three colors, and the red, yellow, blue, and green yarns are respectively used as outer wrapping yarns for wrapping and compounding.

[0114] The hollow spindle speed is 12440r / min, the yarn drawing speed is 34m / min, the wrapping twist is 366 twists / m, the wrapping twist direction is Z twist, and the eccentricity of the converging yarn guide hook is 3mm.

[0115] The color of the wrapped yarn is the determining factor of the overall color of the wrapped yarn. Changing the color of the wrapped yarn will result in a large difference in the overall color of the yarn. From Figure 13 It can be seen that the colors of the outer wrapping yarns are different, and the colors of the yarn segments are different. When the color of the outer wrapping yarns is the same as that of one of the core yarns, the yarn color segments are composed of solid color segme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com