Capping beam structure and construction method thereof

A construction method and technology of covering beams, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of high comprehensive cost and large maintenance workload, and achieve the goal of reducing project cost, reducing the weight and thickness of covering beams. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, by describing a preferred specific embodiment in detail, the feature of the present invention is further elaborated, so that the understanding of those skilled in the art:

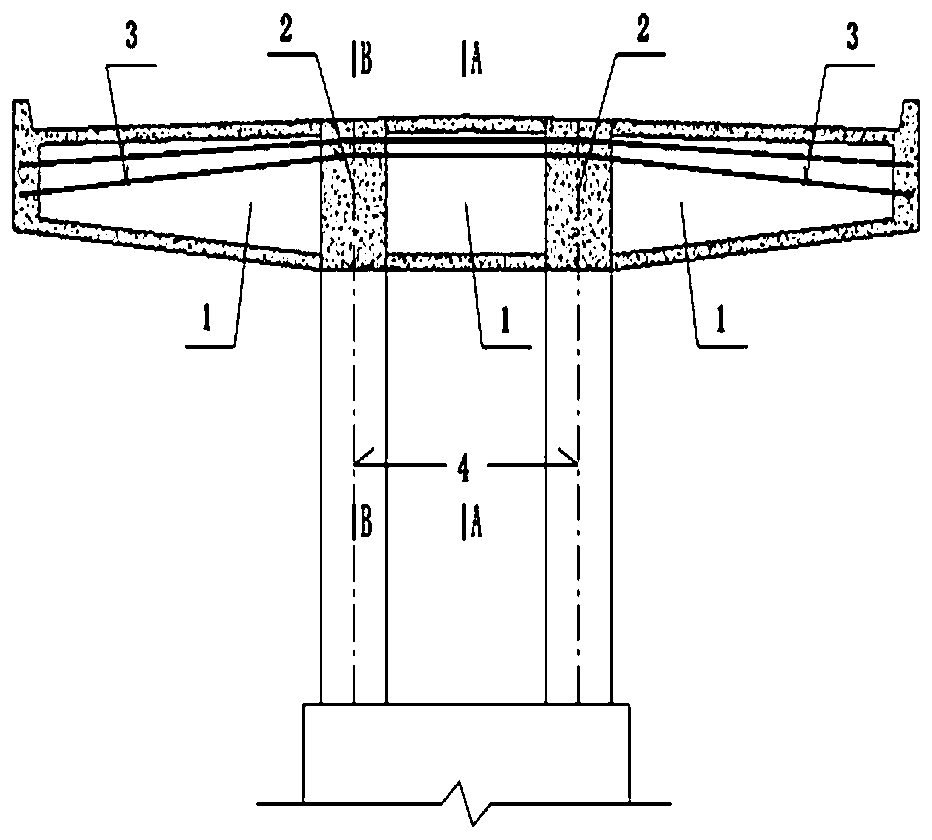

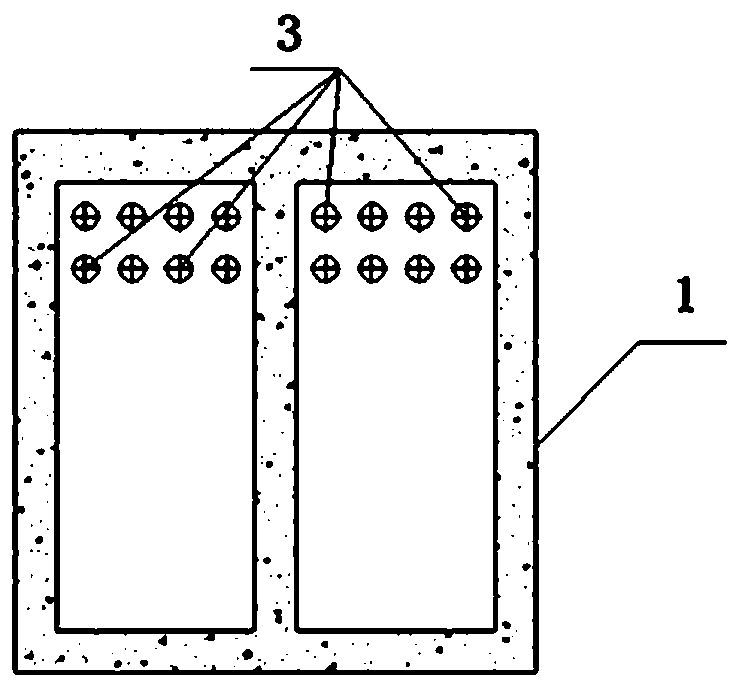

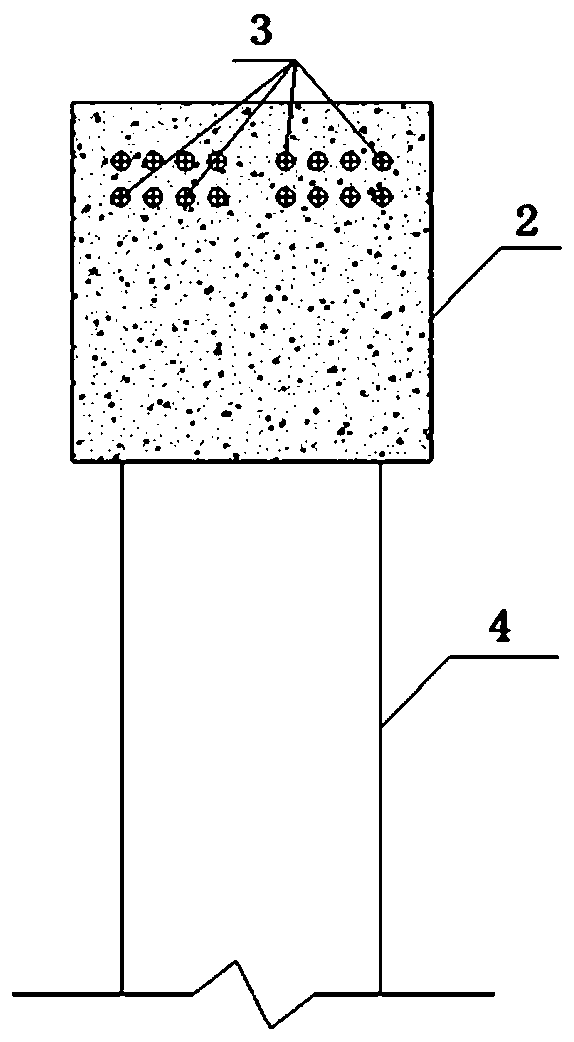

[0039] Such as Figure 1-Figure 3 , the marks in the figure are: hollow structure 1, solid structure 2, external prestressed steel beam 3.

[0040] The hollow structure 1 and solid structure 2 in the new cover beam structure are poured into an integral cover beam structure in the prefabrication factory. The hollow structure 1 is made of ultra-high performance concrete, and the solid structure 2 is made of ordinary concrete. After the overall cover beam structure is maintained to the design strength, the external prestressed steel beam 3 is stretched. After the 3 tensioning and anchoring of the external prestressed steel beams are completed, the prefabricated cover beam structure is transported to the construction site as a whole through the transporta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com