Farmland ditch hydraulic control water spraying equipment for hydraulic engineering

A technology of water conservancy engineering and water spraying equipment, applied in the direction of mechanical equipment, botanical equipment and methods, applications, etc., can solve the problems of low automation, cumbersome operation process, and reduce the efficiency of water spraying in farmland, so as to realize automatic control and save energy the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

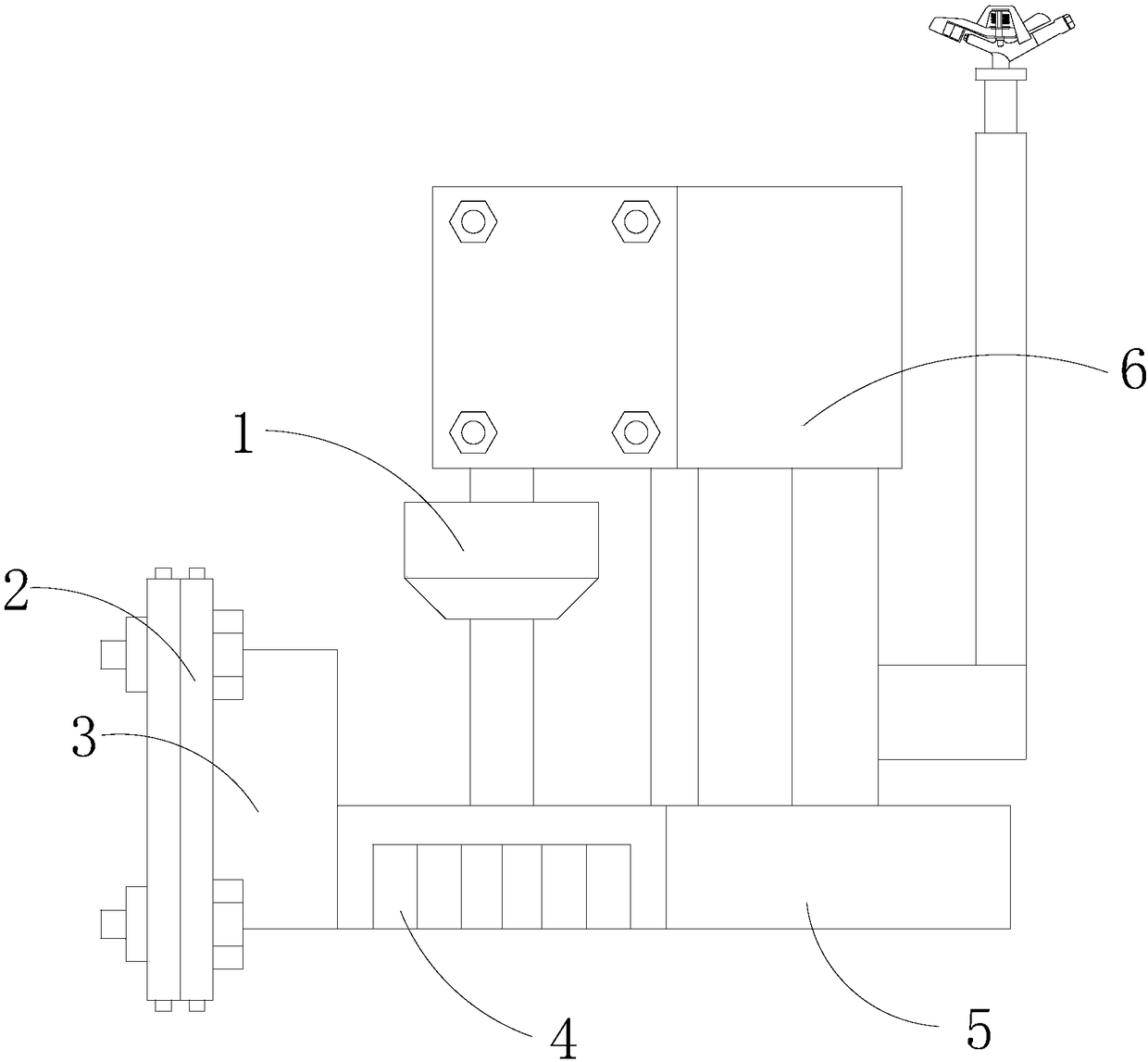

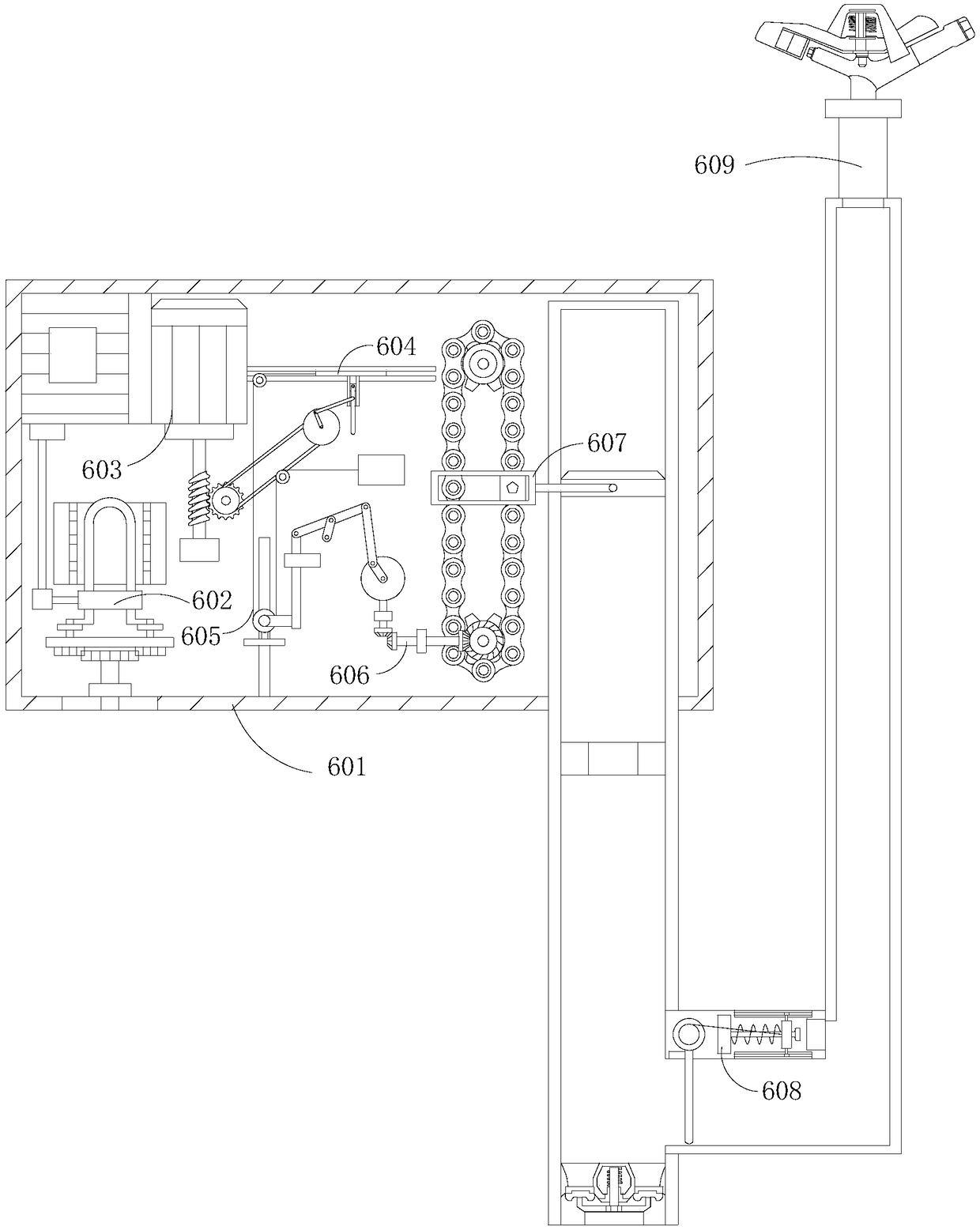

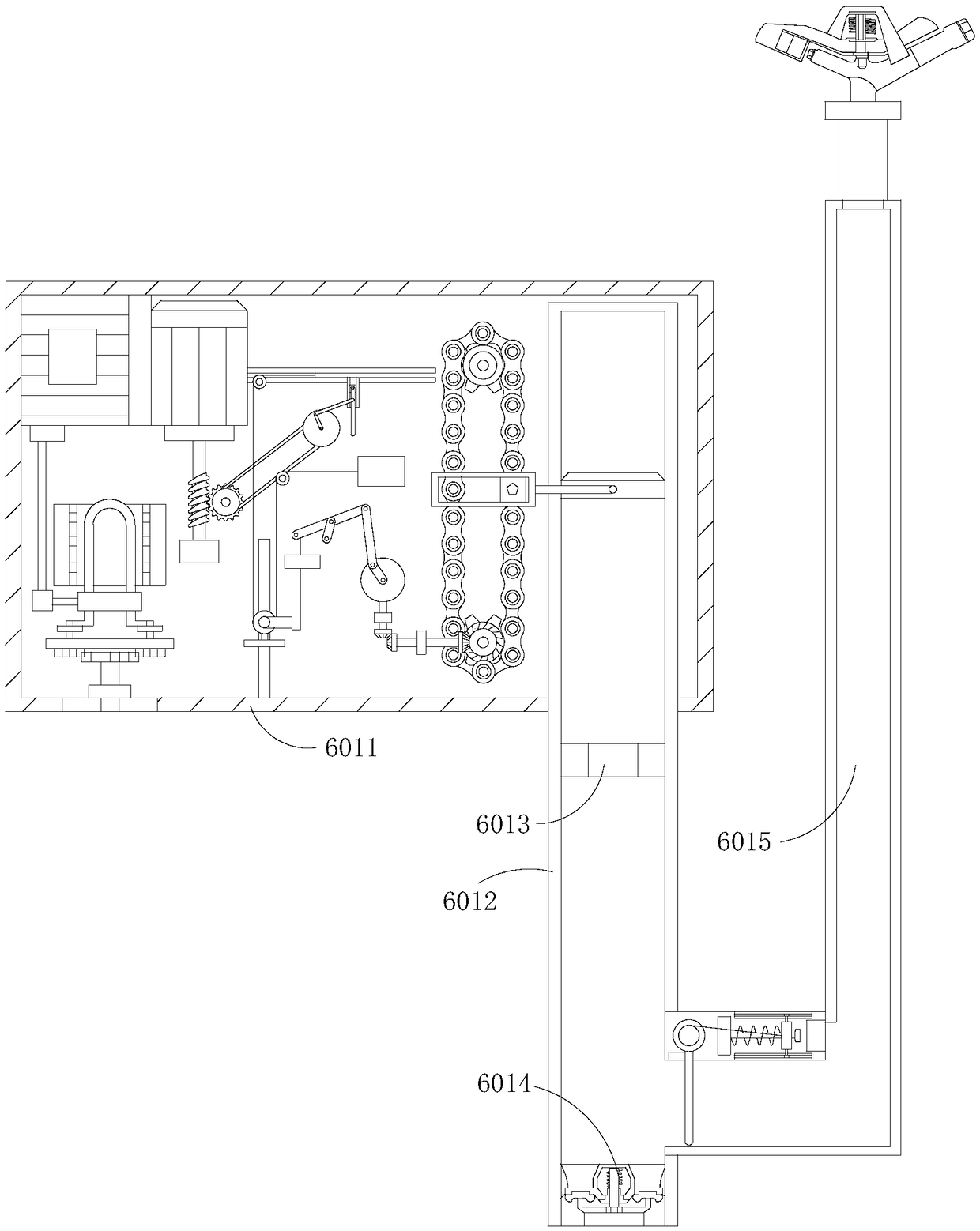

[0026] see Figure 1-Figure 7 , the present invention provides hydraulically controlled water spray equipment for farmland ditches used in water conservancy projects. The water spray control device 6, the top of the shaft cooling device 1 is vertically installed on the bottom of the automatic water spray control device 6, and one end of the connecting channel pipe 2 is connected with the channel 3 by welding, the described One end of the channel 3 is fixedly inlaid with a water turbine 4, the top of the water turbine 4 is mechanically connected to the shaft cooling device 1, the top of the outlet pipe 5 is connected to the bottom of the automatic water spray control device 6, and the The automatic water spray control device 6 includes a support component device 601, a power generating device 602, a braking device 603, a sliding mechanism 604, a lifting structure 605, a transmission mechanism 606, a water pumping structure 607, an adjustment mechanism 608, and a water spraying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com