Efficient mixed-flow pump with self-cooled submersible motor

A submersible motor and mixed-flow pump technology, which is applied to the components, pumps, and pumping devices of elastic fluid pumping devices, can solve the situation where the motor cannot be submerged, the large hydraulic loss of the motor wellbore tee, the guide vane, etc. Problems such as large diffusion loss, to achieve the effect of reducing shaft length, low flow channel loss, and small diffusion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

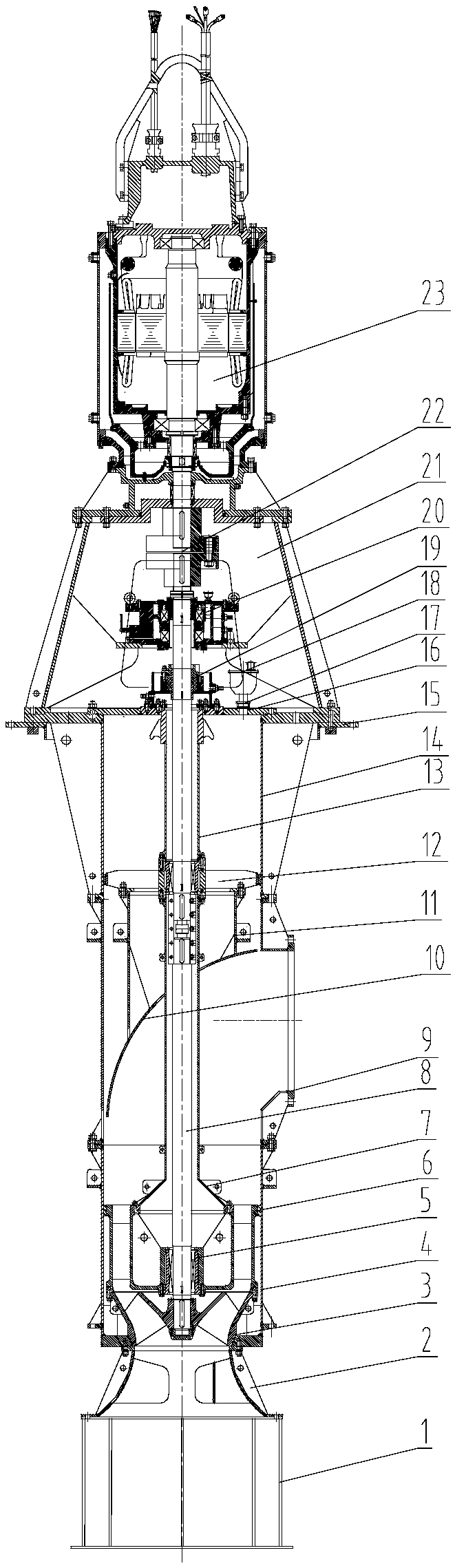

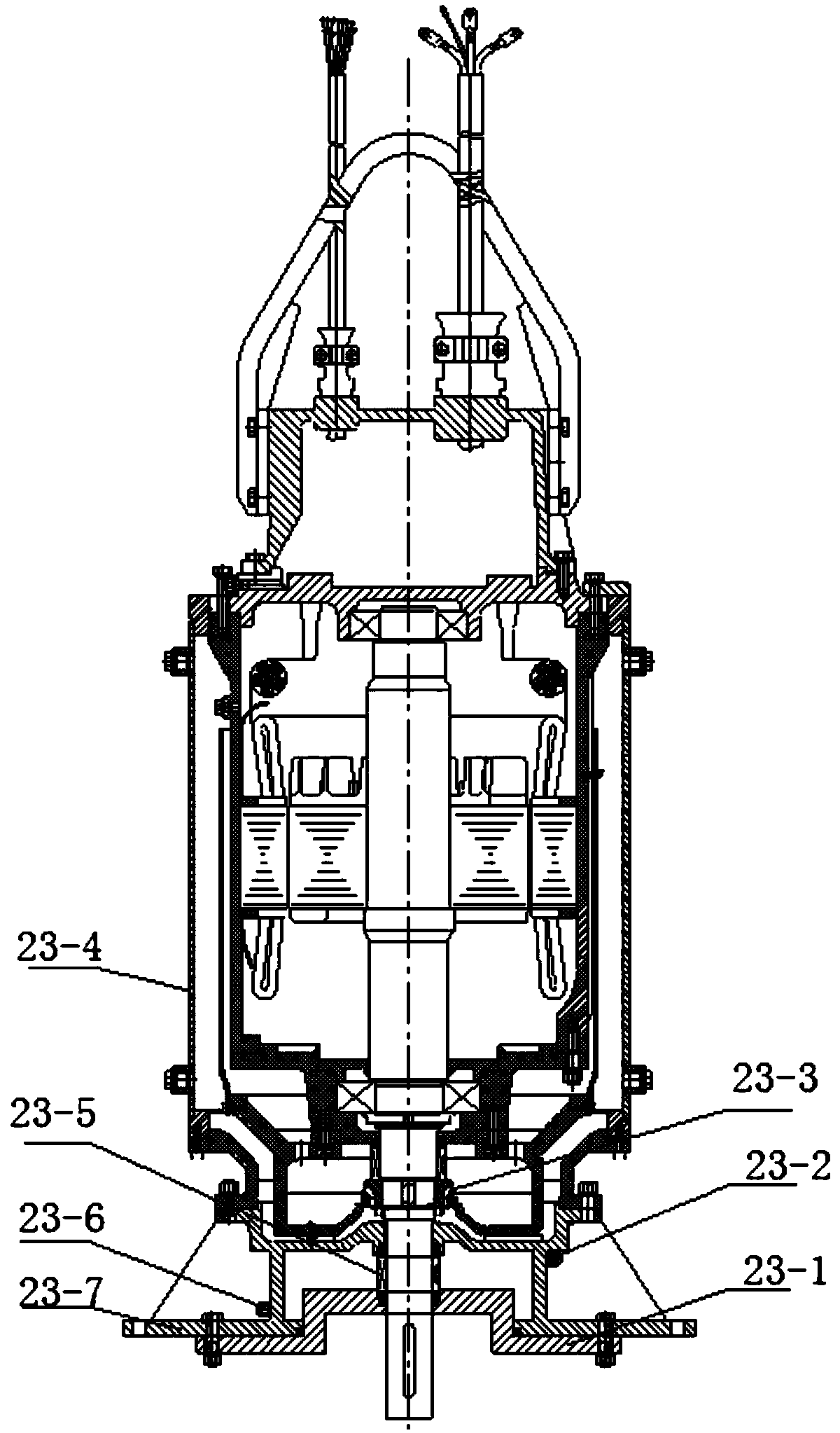

[0026] See attached picture.

[0027] A high-efficiency mixed-flow pump with a self-cooling submersible motor, which adopts a core-pulling structure, and includes a cylinder and a core. The cylinder includes a pump seat 14 composed of long pipes 4. One of the pump seats 14 The side is connected to the elbow 9 through the inner connecting pipe 10 and the deflector 11. The bottom end of the pump seat 14 is equipped with a water inlet bell mouth 2, and the bottom end of the water inlet bell mouth 2 is installed with a suction net cover 1. The core is located in the cylinder, and includes a rotor part 8, the bottom end of the rotor part 8 is equipped with a guide vane body 6 through a bearing 5, and a runner chamber 3 is installed at the bottom end of the guide vane body 6. The upper end of the vane body 6 is equipped with a conical tube 7 sleeved on the rotor part 8, the upper end of the conical tube 7 is provided with an inner protective tube 13 matched with it, and the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com