Inspection tool for detecting oil hole position of main journal and connecting rod neck of crankshaft

A technology for main journals and connecting rod journals, which is applied in the field of inspection tools for detecting the position of crankshaft main journals and connecting rod journal oil holes. It can solve the problems of scrapping crankshafts in batches, cumbersome operations, and time-consuming inspections, and reduce the scrapping rate of products. , Improve detection efficiency, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments.

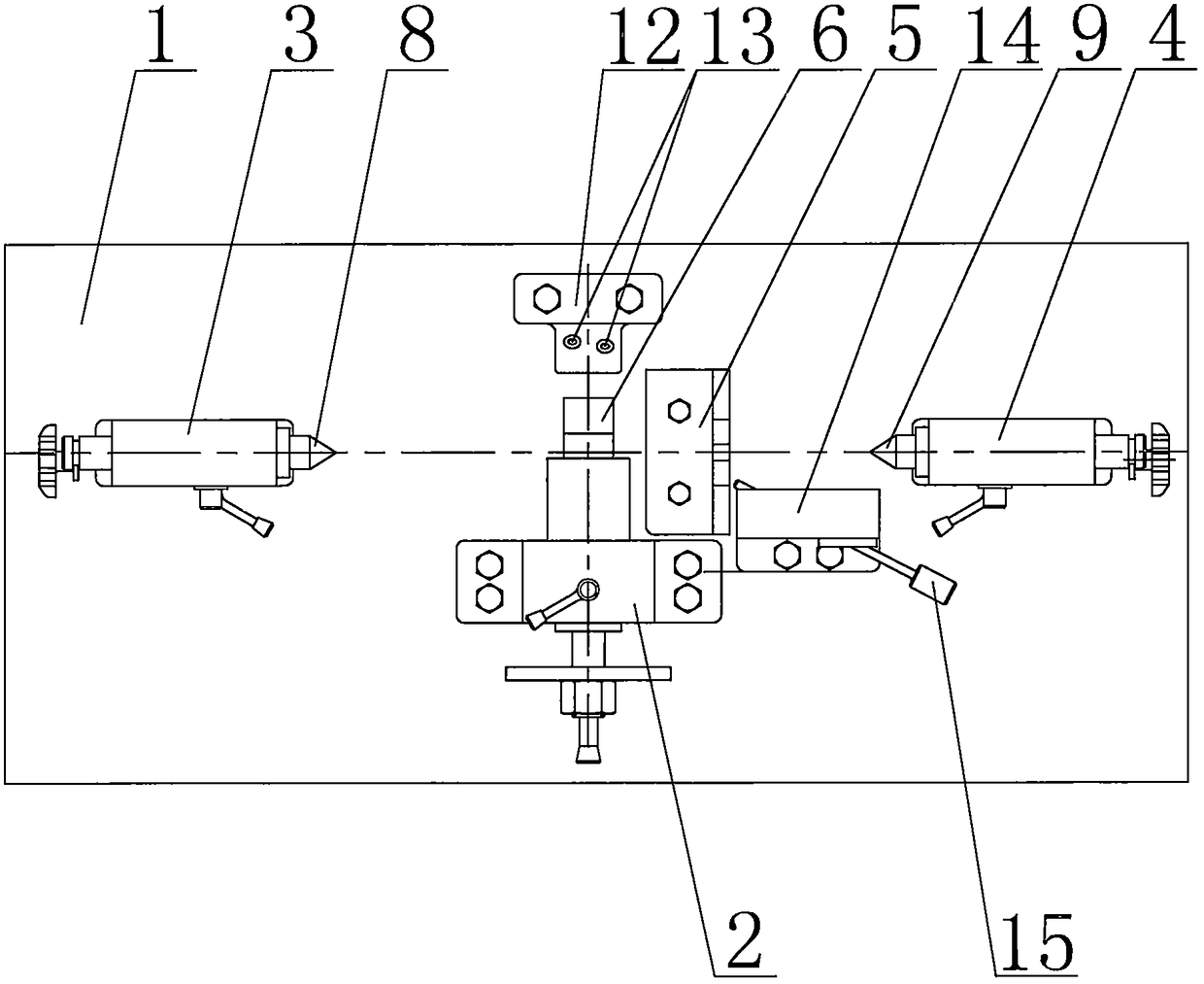

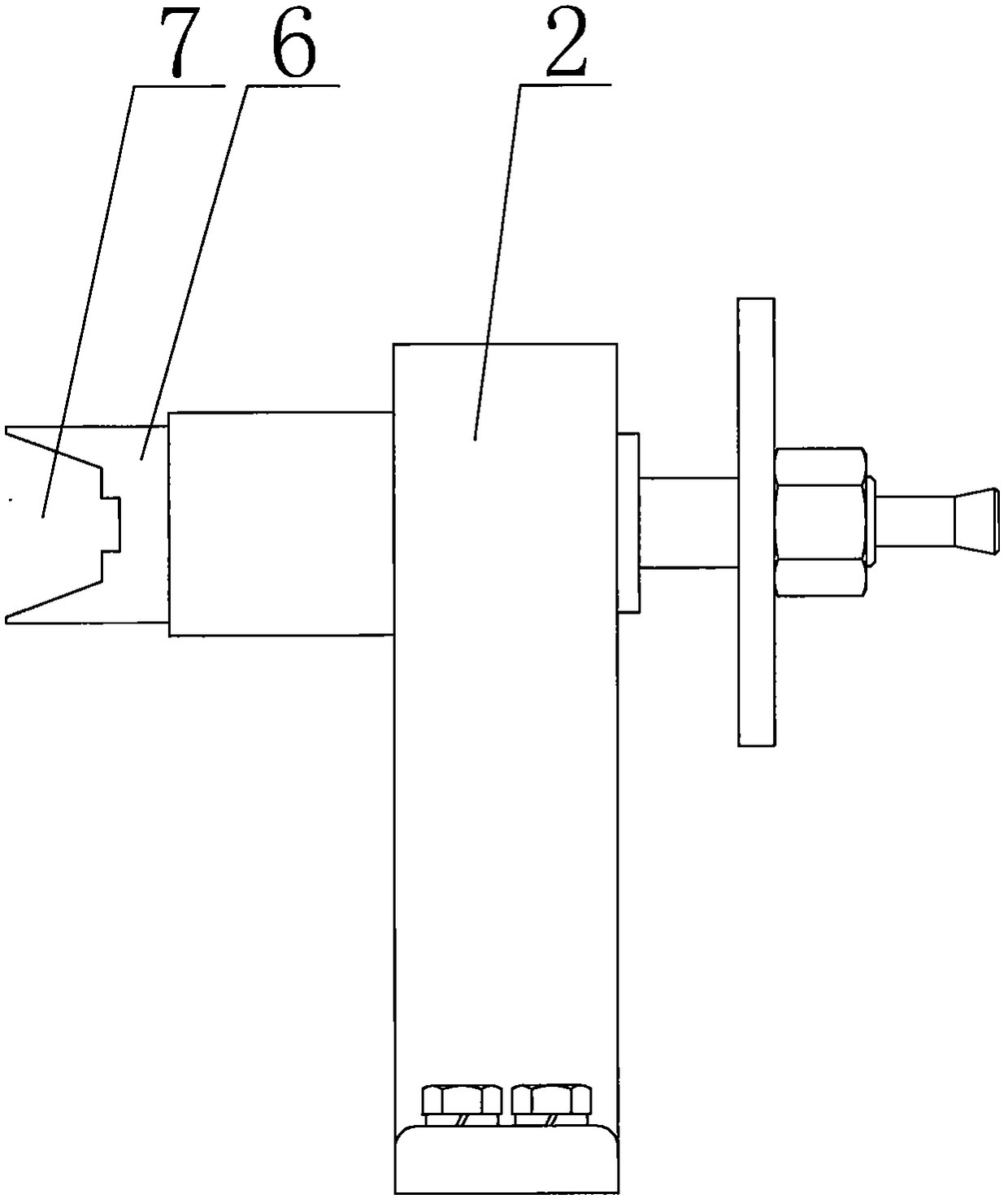

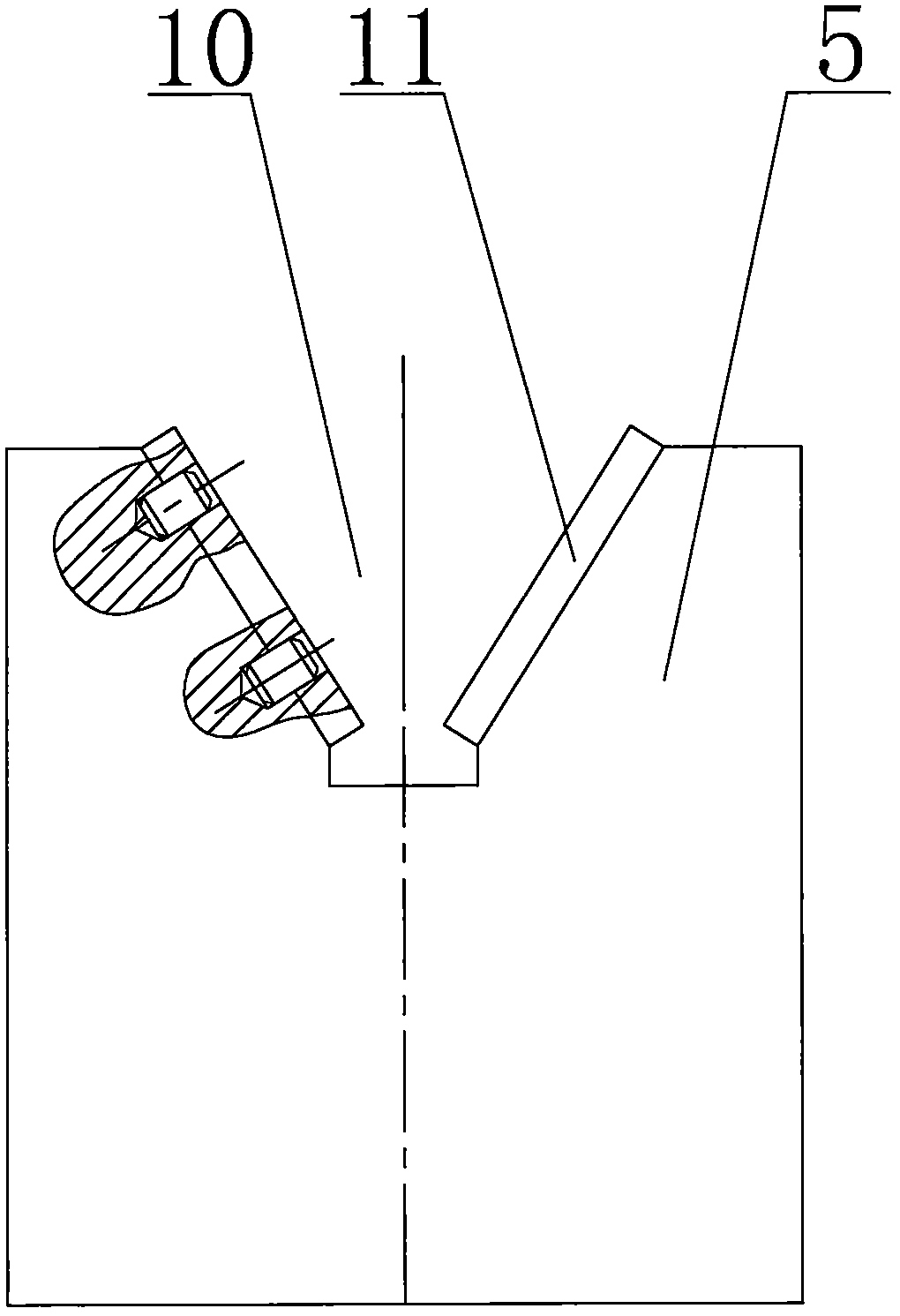

[0012] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses a checker for detecting the position of the crankshaft main journal and connecting rod neck oil hole, including a base plate 1, a top seat 2, a top seat 2 3, a top seat 3 4 and a V-shaped positioning frame 5, A top seat-2 is fixed on the bottom plate 1 near the middle position, a V-shaped positioning block 6 is arranged in the installation hole at one end of the top seat-2, and a V-shaped groove-7 is provided in the middle of the V-shaped positioning block 6, and the bottom plate 1 is located on the V-shaped positioning block. Two sides of the shape positioning block 6 are symmetrically fixed with top seat tw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap