Method for rapidly measuring steel slag residue water content

A technology for rapid determination of residual moisture content, applied in measuring devices, by removing certain components, weighing, instruments, etc., it can solve the problems of pollution, different attention and utilization of steel slag, affecting people's work and life, etc. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

[0026] (1) Prepare test equipment and test materials

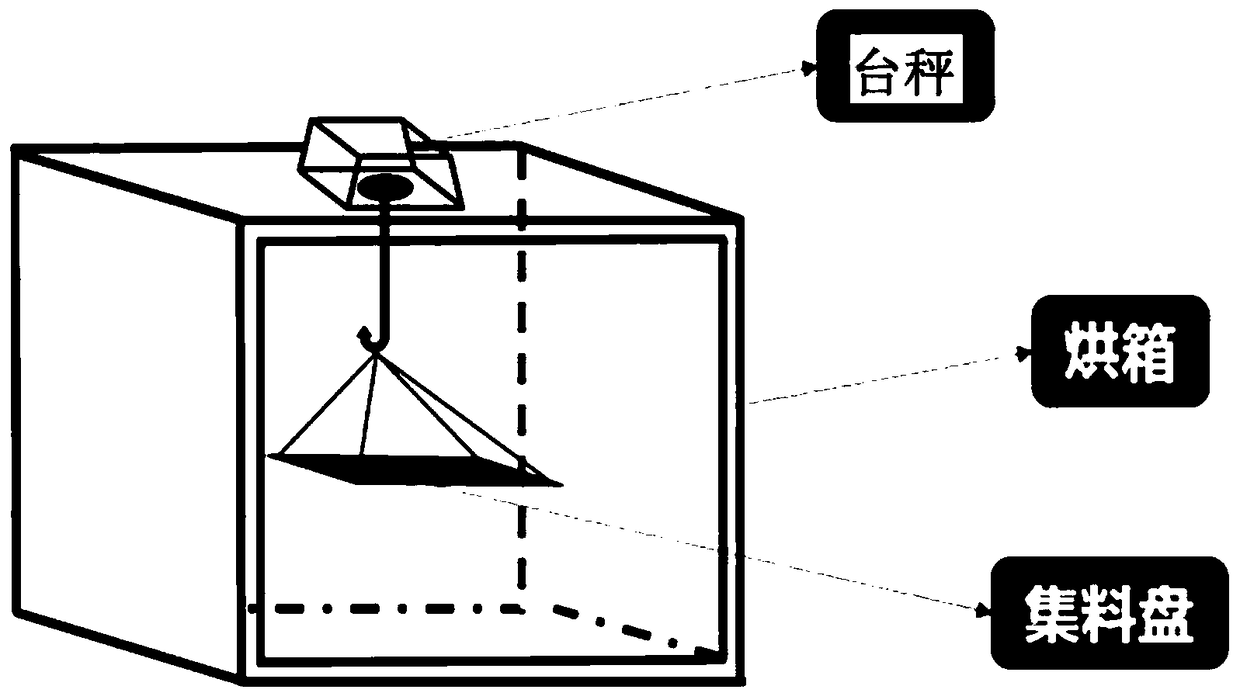

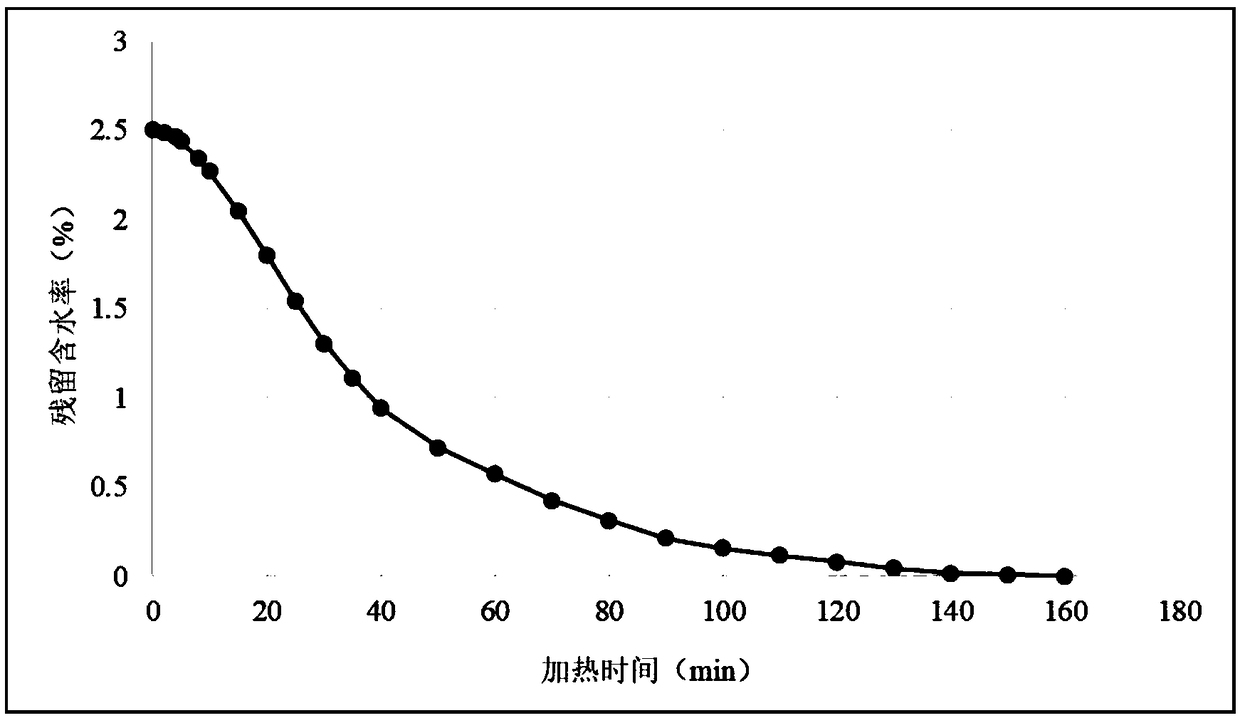

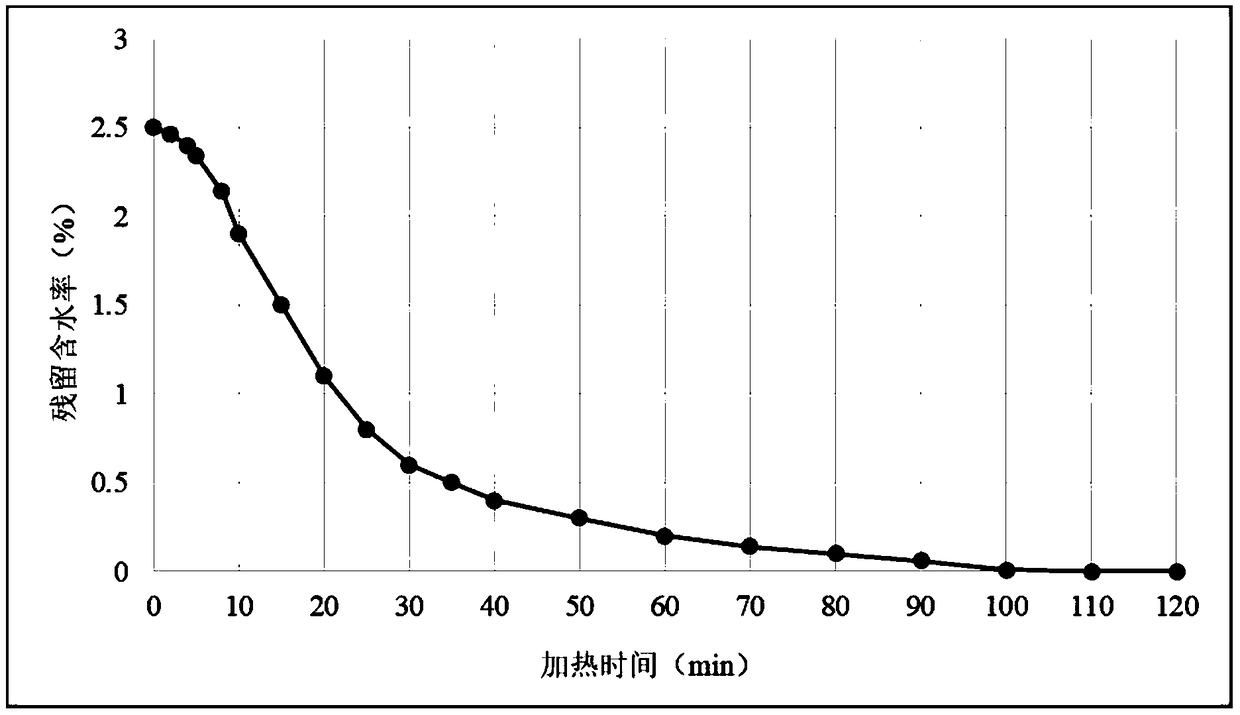

[0027] Firstly, design the test scheme of the change law of the moisture content of steel slag with the heating time. The test equipment can be obtained by simple combination of oven, platform scale, collecting pan and other devices. For the test equipment, refer to the attached figure 1 shown. The purpose of the design of the test device is to measure the mass loss of the aggregate in the environment where the aggregate is dried in an oven to simulate the mixing station, and the mass lost is the mass of the water emitted. Then set the initial heating state of steel slag. In order to obtain the maximum water content range of steel slag, it can be set to keep the sampled steel slag for 24 hours under the condition of water immersion. It can be con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com