Magnetic resonance effect based imprinting sensor

A sensor and effect technology, applied in the field of magnetic resonance effect imprinting sensors, can solve the problems of simple function, single detection method, and inability to provide imprint measurement functions, etc., to improve measurement accuracy, overcome non-specificity, strong versatility and portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

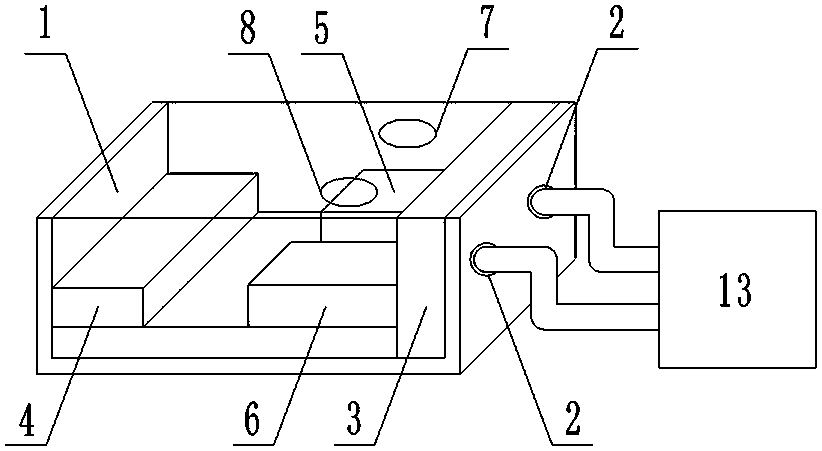

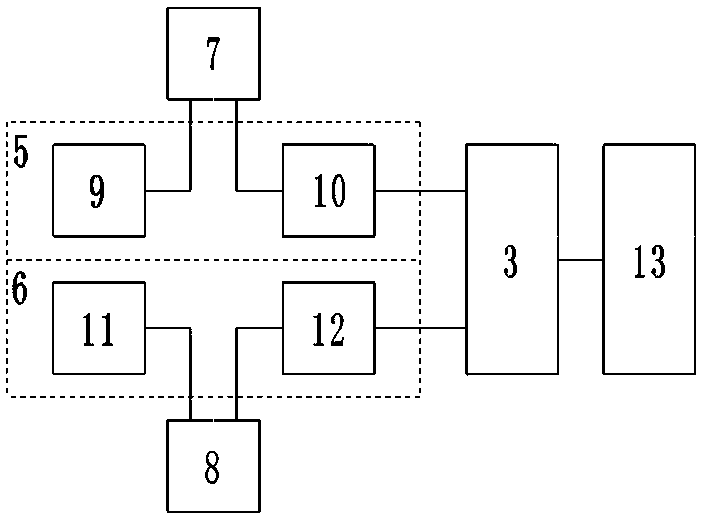

[0072] Such as Figure 1 to Figure 5 As shown, the magnetic vibration effect imprint sensor of the present invention includes a housing 1, and one end of the housing 1 is provided with a data output port 2, and the field communication bus is connected to the central controller 3 through the data output port 2;

[0073] The central controller 3 is arranged on one side of the housing 1, and the other side of the housing 1 is provided with a magnet bar 4, and a pair of sensing modules are arranged in parallel between the central controller 3 and the magnet bar 4, Including a first magnetoelastic ion imprint sensing module 5 and a second magnetoelastic ion imprint sensing module 6;

[0074] A first coil 7 is also arranged above the first magnetoelastic ion imprint sensing module 5, and a second coil 8 is also arranged above the second magnetoelastic ion imprint sensing module 6;

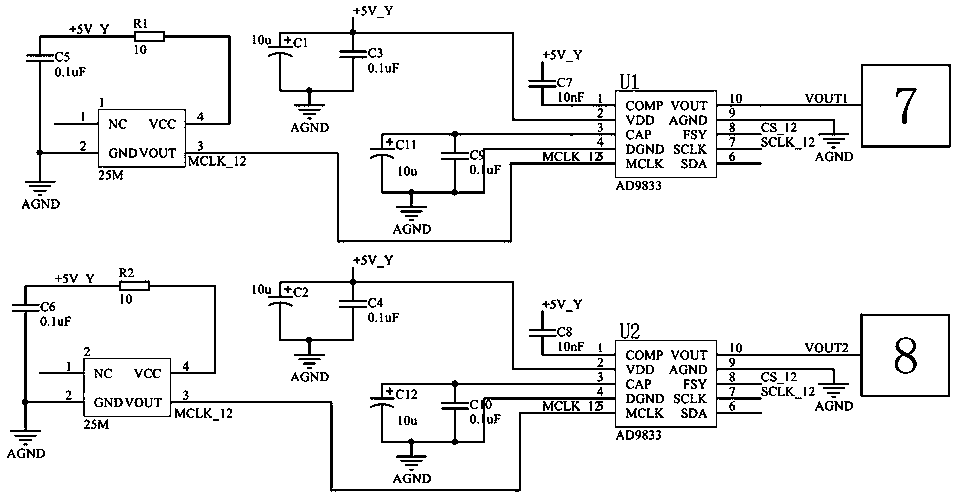

[0075] The first magnetoelastic ion imprint sensing module 5 includes a first waveform generation mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com