Method for evaluating aging degree of pantograph pan based on ultrasonic wave

A technology of pantograph sliding plate and aging degree, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, analytical materials, etc., can solve the problems of low maintenance efficiency, prone to false detection, waste of human, material and financial resources, etc. Inaccuracy issues, fast evaluation methods, high precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

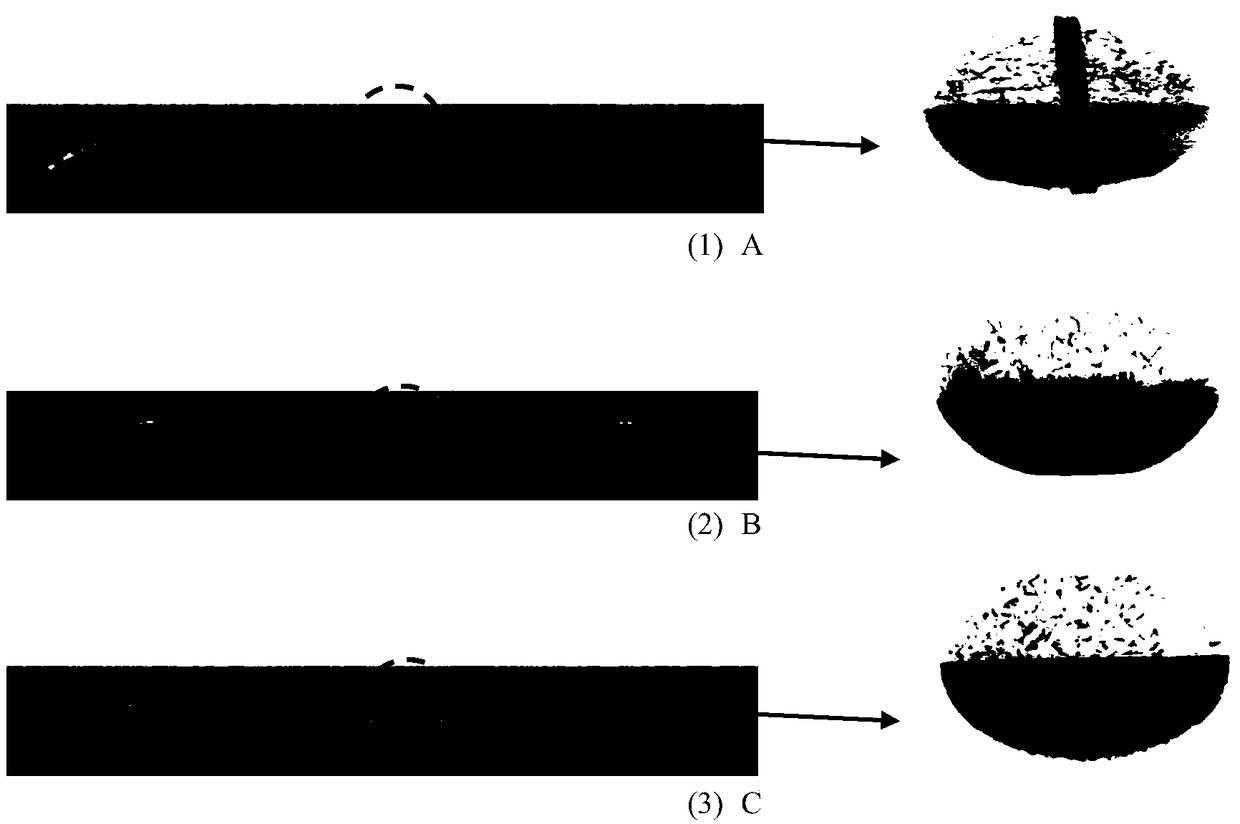

[0015] 1) Select three pantograph carbon slides with different degrees of wear on site as the evaluation objects of aging degree, such as figure 2 shown.

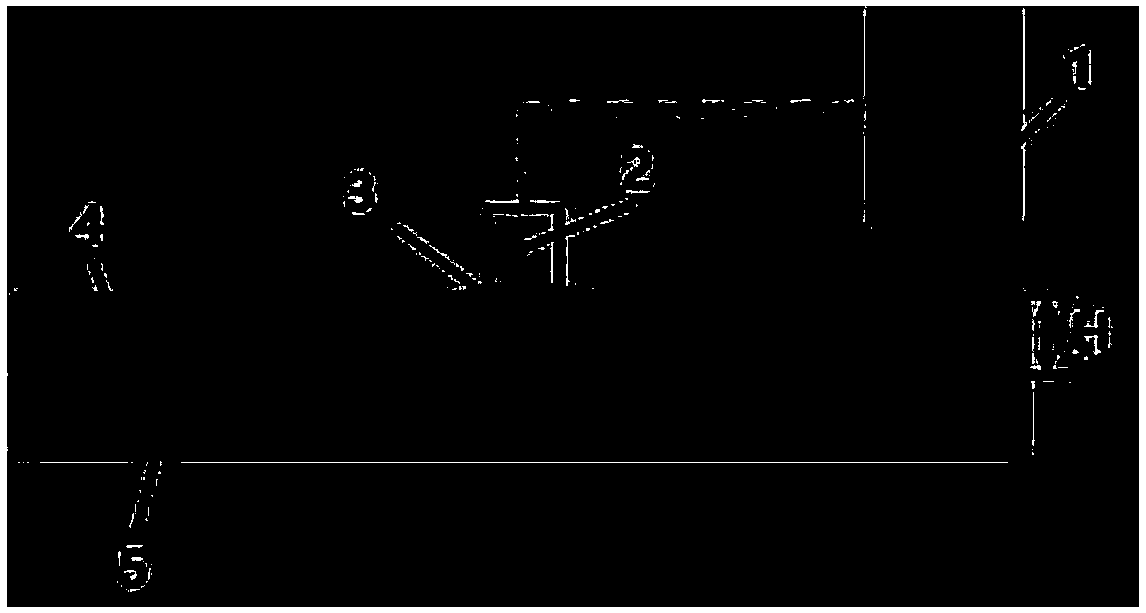

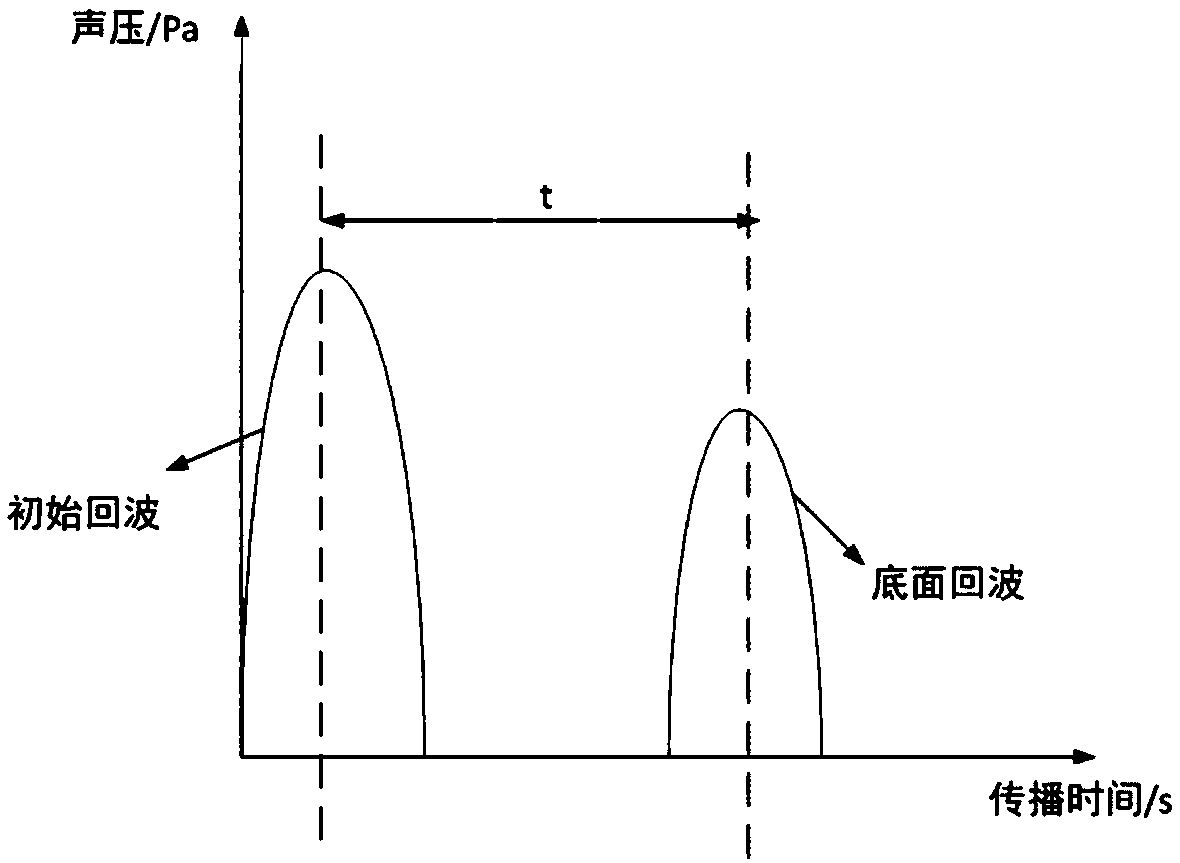

[0016] 2) Measure the propagation speeds of ultrasonic waves in the three pantograph slides respectively. The ultrasonic flaw detector 1 is selected as the ultrasonic sound velocity measurement equipment, and the ultrasonic probe 2 with a suitable frequency and diameter is selected for the ultrasonic sound velocity measurement. Before the measurement, the performance of the ultrasonic probe was measured and calibrated on the standard test block. During the measurement, glycerin was selected as the coupling agent 3 and applied to the pantograph slide (see figure 1 , Skateboard structure: the upper surface of the aluminum alloy bracket 5 is the carbon strip 4) upper surface, place the ultrasonic probe on the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com