Online monitoring method for partial discharge of high-voltage feeder cables of electrified railway

A technology of electrified railway and partial discharge, applied in the direction of test circuit, measuring electricity, measuring device, etc., can solve the problems of large noise, few related documents, large error of discharge signal, etc., and achieve the effect of preventing breakdown accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

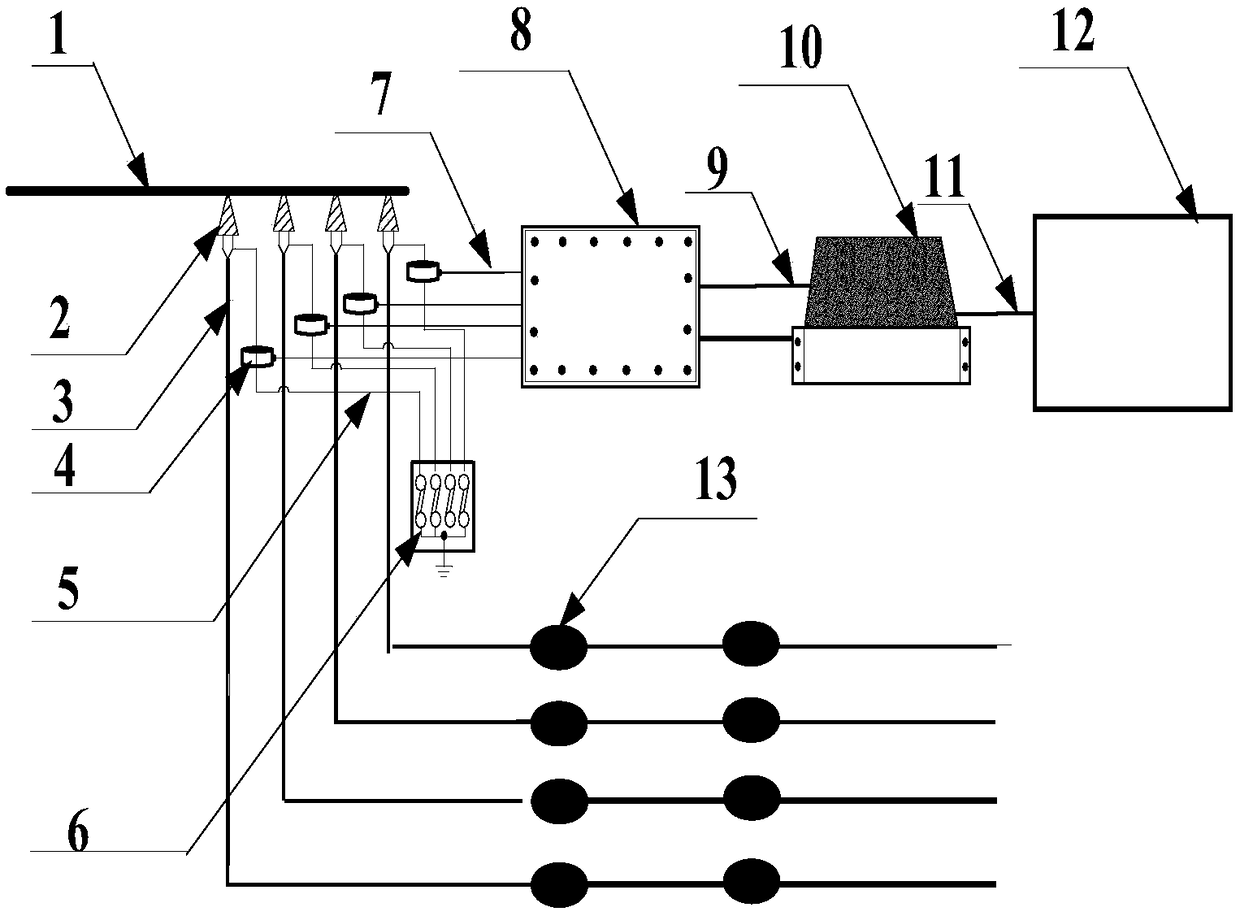

[0021] The invention provides an on-line monitoring method for partial discharge of high-voltage feeder cables of electrified railways. figure 1 As shown, the bare conductor 1 of the railway locomotive power supply feeder in the figure is connected to the railway catenary at one end, and connected to the feeder cable connector 2 at the other end, and the feeder cable connector 2 is connected to the feeder cable 3, and is connected to the traction transformer , each cable joint 2 has a cable grounding wire 5 grounded through the grounding box 6, forming a connection mode from the traction transformer to the primary equipment of the feeder section.

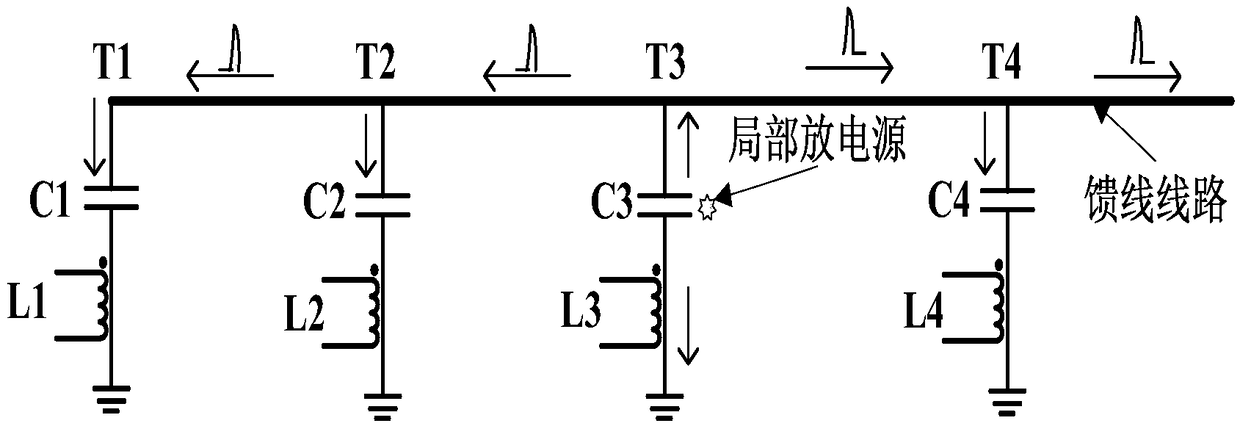

[0022] This embodiment takes four high-voltage feeder cables 3 as an example for illustration. This embodiment uses four high-frequency current transformers 4 (HFCT) clamped on each cable grounding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com