Quality control method for degraded profile in processing course of blade of aviation engine

A quality control method and aero-engine technology, which are applied in the contour quality control of aero-engine blade machining process degradation, and in the field of contour quality control during engine blade machining process, and can solve the problems of low contour quality control accuracy and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

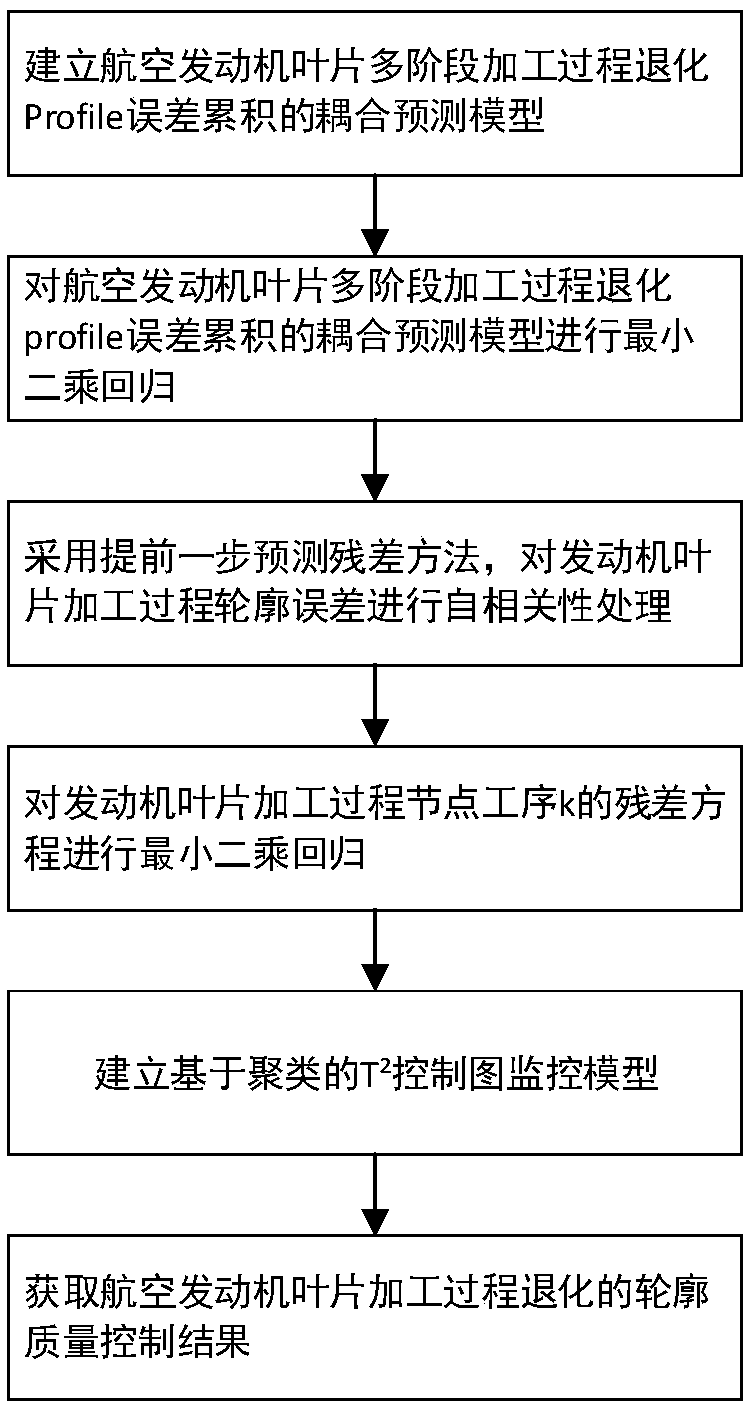

[0063] refer to figure 1 , the implementation steps of the present invention are as follows:

[0064] Step 1) Establish a coupling prediction model for the accumulation of degradation Profile errors in the multi-stage machining process of aero-engine blades:

[0065] Step 1a) Analyze the multi-source errors that affect the degradation of the aeroengine blade machining process:

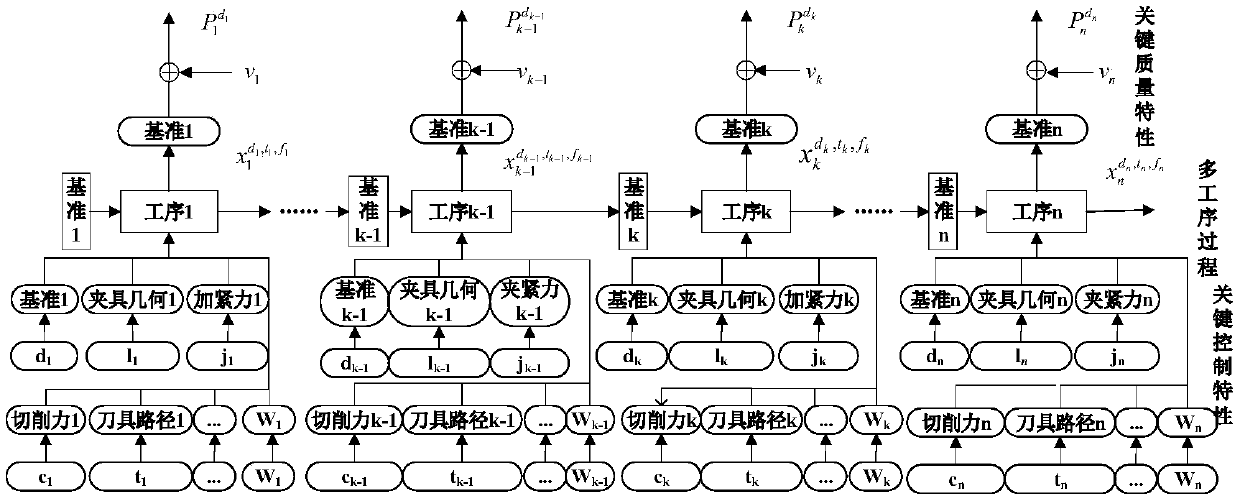

[0066] Passing principle through state space and error flow, refer to figure 2 , to determine the error sources in the machining process of aero-engine blades are divided into reference errors; machining errors caused by tool paths; fixture geometry errors; workpiece deformation errors caused by cutting forces; noise errors; error transfer analysis and machining process degradation mechanism analysis of engine blades, The coefficient expression of engine b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com