Chaos-based agile and high-precision optimal soft measurement meter for propylene polymerization production process

An optimal soft measurement and propylene polymerization technology, applied in the direction of instruments, program control, electrical program control, etc., can solve the problems of slow speed and low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in detail below based on the drawings.

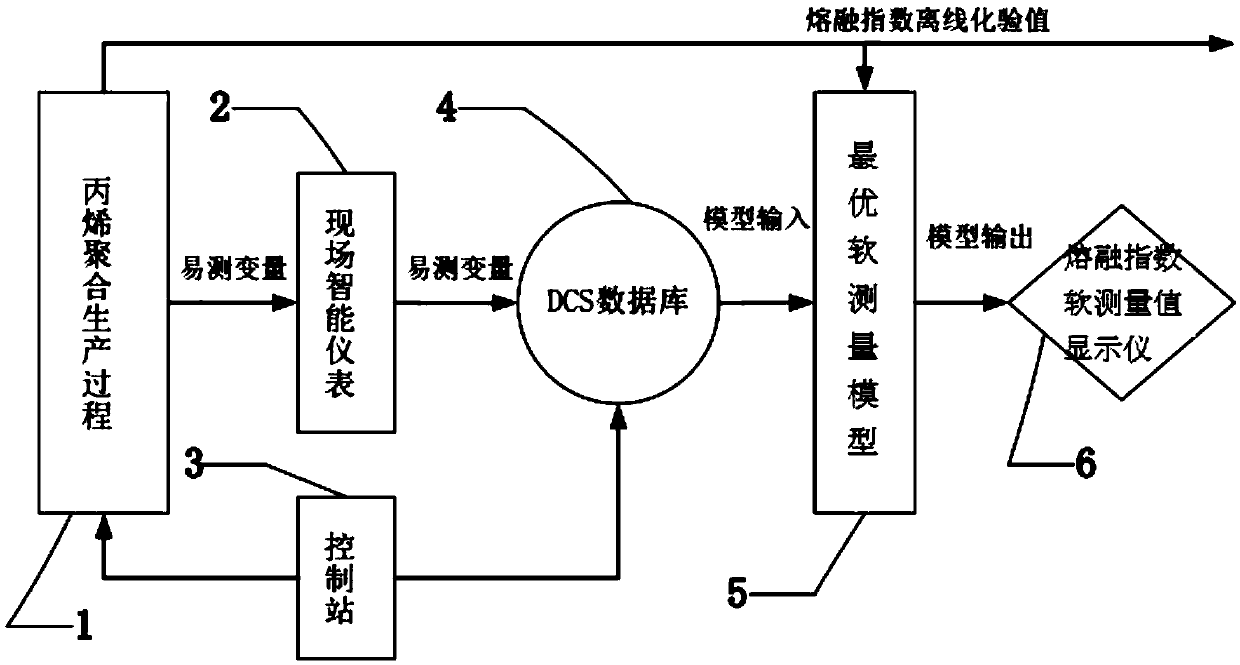

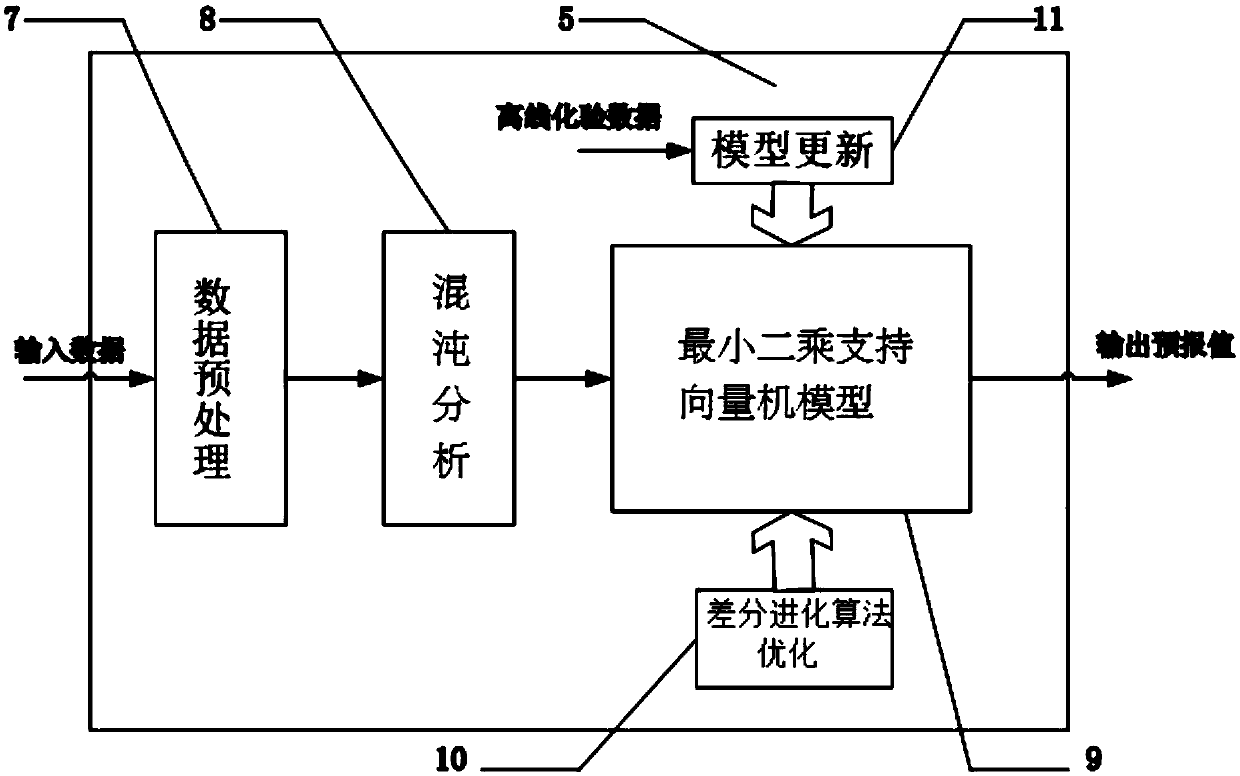

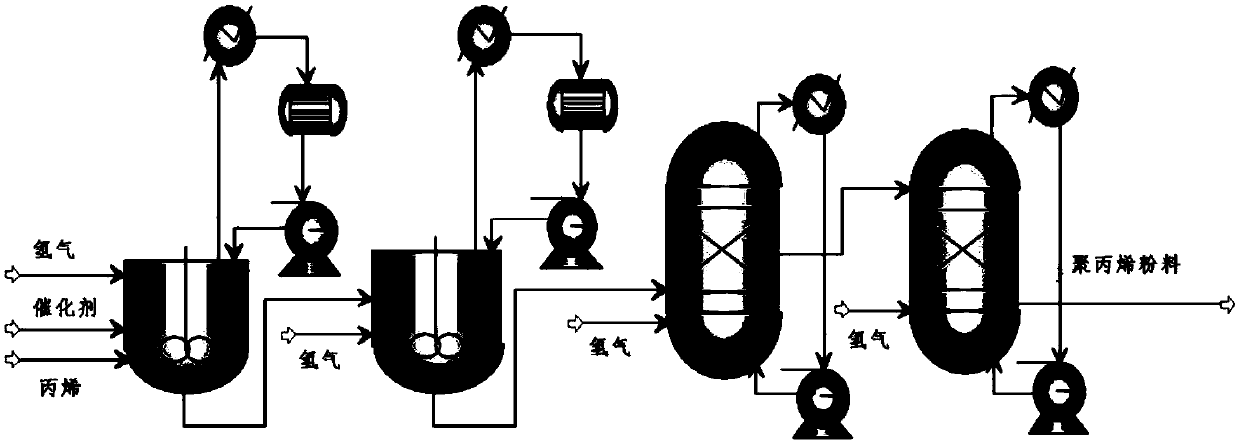

[0072] Reference figure 1 , A chaotic, agile and high-precision optimal soft-measuring instrument for propylene polymerization production process, including propylene polymerization production process 1, on-site intelligent instrument for measuring easy-to-measure variables 2, control station for measuring operating variables, 3, data storage The DCS database 4 and the melt index soft measurement value display instrument 6, the on-site intelligent instrument 2, the control station 3 are connected to the propylene polymerization production process 1, the on-site intelligent instrument 2, the control station 3 are connected to the DCS database 4, and the software The measuring instrument also includes an optimal soft sensor model 5 based on the differential evolution algorithm optimized chaotic least squares least squares support vector machine, the DCS database 4 and the differential evolution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com