39-slot 12-pole three-phase permanent magnet synchronous motor six-layer nested winding embedding connection method

A permanent magnet synchronous motor and three-phase winding technology, which is applied to the shape/style/structure of winding conductors, electromechanical devices, electrical components, etc. Bodo and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

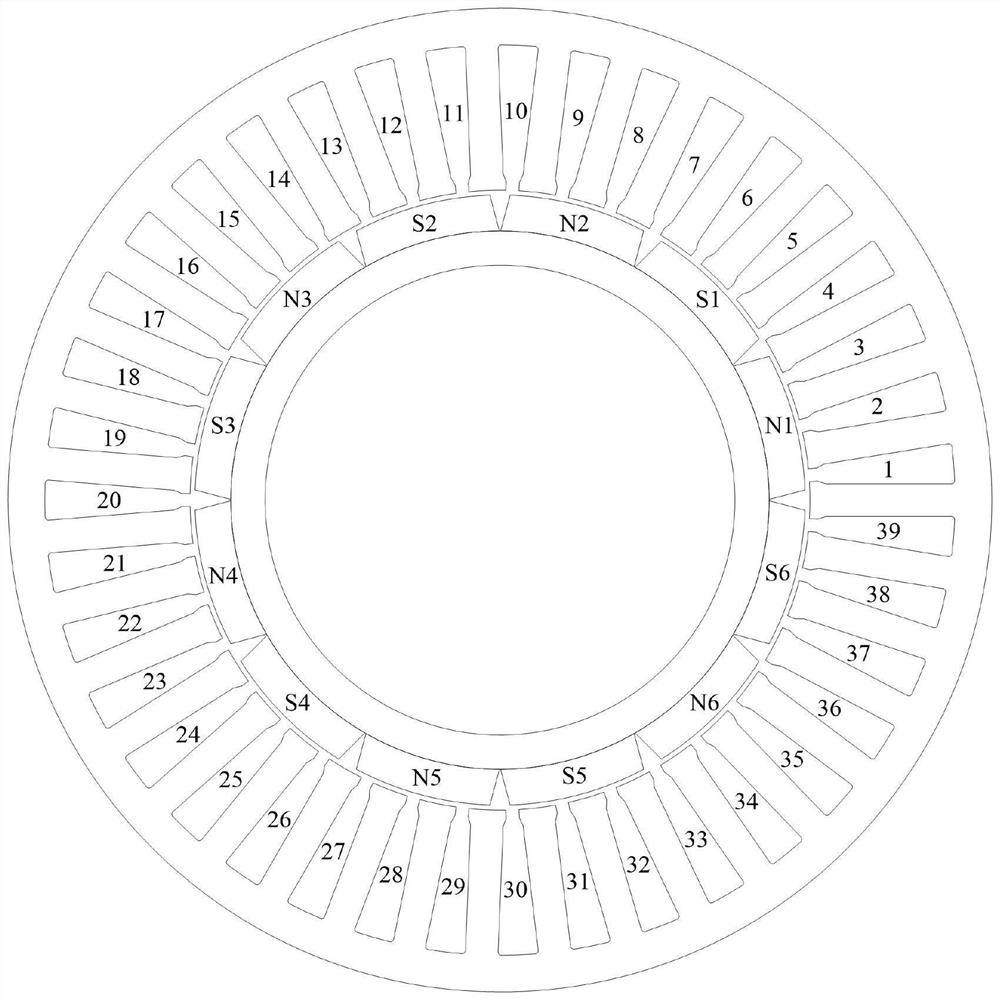

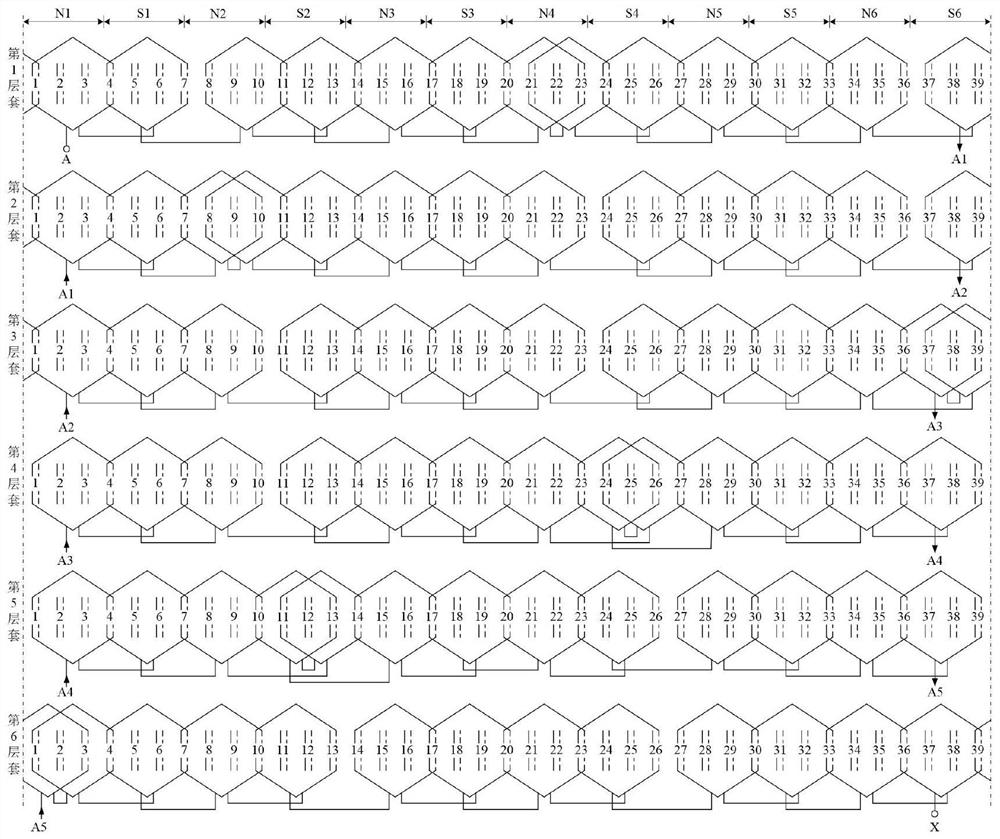

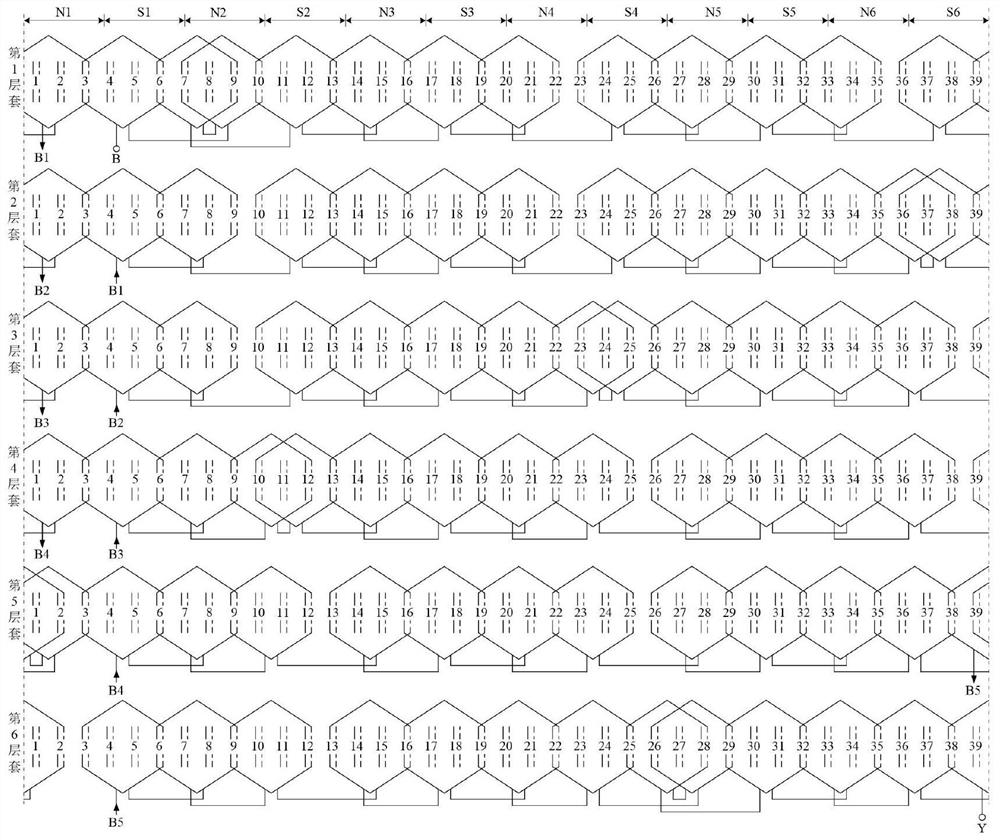

[0023] combine Figure 1 to Figure 5 The implementation of the embedding and connection of six-layer nested windings suitable for 39-slot 12-pole three-phase permanent magnet synchronous motor proposed by the present invention is given.

[0024] exist figure 1 In the cross-sectional schematic diagram of the 39-slot 12-pole three-phase permanent magnet synchronous motor shown, the number in the stator slot represents the slot number, the coil number of each coil in each layer and the slot number of the slot embedded in the lower side of the coil same.

[0025] The coil number is the same as the slot number in each layer of sleeves. The coil lead end at the lower side of each coil is called the head end of the coil, and the coil lead end at the upper layer side of each coil is called the tail of the coil. end; the embedding rule of 39 coils in each layer is: first insert the lower side of the layered coil 1 into the slot 1, and then embed the lower side of the layered coil 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com