Switched reluctance motor for electric automobile

A switched reluctance motor, electric vehicle technology, applied in electric vehicles, motors, synchronous motors for single-phase current, etc., can solve problems such as excessive magnetic density, reduce losses, reduce motor mutual inductance, and improve output Effects of torque and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

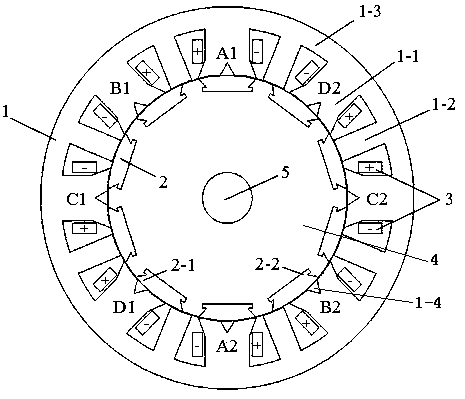

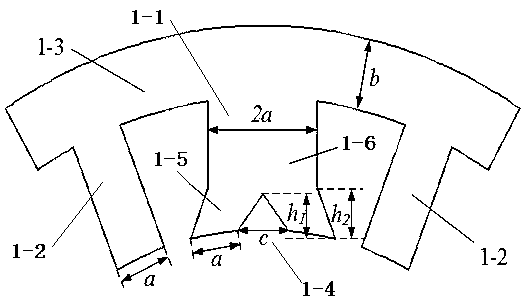

[0016] see figure 1 , the outside of the present invention is the stator 1, and the stator 1 is formed by laminating silicon steel sheets. The inner coaxial sleeve of the stator 1 is provided with a rotor sleeve 4 , and the center of the rotor sleeve 4 is coaxially fixedly sleeved outside the rotating shaft 5 . Stator 1 is composed of stator yoke 1-3 and stator teeth. A plurality of stator teeth are evenly arranged on the inner wall of stator yoke 1-3 along the circumferential direction. Stator teeth are composed of bifurcated excitation teeth 1-1 and auxiliary teeth 1-2. The number of excitation teeth 1-1 and auxiliary teeth 1-2 are equal and arranged alternately.

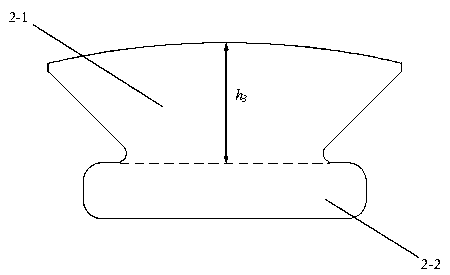

[0017] On the outer wall of the rotor sleeve 4, a plurality of segmented rotors 2 are evenly arranged along the circumferential direction. The segmented rotors 2 are made of laminated silicon steel sheets. Slot holes equal to the number of segmented rotors 2 are evenly processed to fix the segmented rotors 2 so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com