Multifunctional coating applicable to medical implantable device

A multi-functional coating and functional technology, applied in coatings, medical science, prostheses, etc., can solve problems such as antibiotic resistance and weakened antibacterial efficiency of coatings, and achieve simple equipment and promote cell adhesion and proliferation and anti-fouling performance, the effect of a wide range of monomer sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A multifunctional coating applicable to medical implant devices and a preparation method thereof, the specific steps are as follows:

[0039] Step a) Synthesis of amphiphilic zwitterionic functional polymer: Weigh 2.201g (14mmol) dimethylaminoethyl methacrylate, 1.250g (6mmol) isobornyl acrylate and 0.034g (1%) 2,2- Azobisisobutyronitrile was added to 20 mL of dioxane, deoxygenated by nitrogen gas for 30 min, and reacted at 65°C for 24 h. After the reaction, the precipitation was repeated three times in petroleum ether to obtain a spare polymer. Dissolve 2 g of spare polymer in 10 mL of dioxane, add 0.071 g of propane sultone, and react at room temperature for 12 hours. After the reaction, the reaction solution is concentrated by rotary evaporation, precipitated in ether three times, and dried in vacuo Finally, an amphiphilic zwitterionic functional polymer with a sulfonation rate of 10% is obtained.

[0040] Step b) preparation of the complex colloid solution: dissol...

Embodiment 2

[0043] A multifunctional coating applicable to medical implant devices and a preparation method thereof, the specific steps are as follows:

[0044] Step a) Synthesis of amphiphilic zwitterionic functional polymer: Weigh 1.572g (10mmol) dimethylaminoethyl methacrylate, 2.083g (10mmol) isobornyl acrylate and 0.068g (1.5%) 2,2- Azobisisobutyronitrile was added to 20 mL of dioxane, deoxygenated by nitrogen gas for 30 min, and reacted at 65°C for 24 h. After the reaction, the precipitation was repeated three times in petroleum ether to obtain a spare polymer. Dissolve 2 g of spare polymer in 10 mL of dioxane, add 0.212 g of propane sultone, and react at room temperature for 12 hours. After the reaction, the reaction solution is concentrated by rotary evaporation, precipitated in ether three times, and dried in vacuo Finally, an amphiphilic zwitterionic functional polymer with a sulfonation rate of 30% is obtained.

[0045] Step b) Preparation of the complex colloid solution: Dis...

Embodiment 3

[0048] A multifunctional coating applicable to medical implant devices and a preparation method thereof, the specific steps are as follows:

[0049] Step a) Synthesis of amphiphilic zwitterionic functional polymer: Weigh 0.944g (6mmol) dimethylaminoethyl methacrylate, 2.916g (14mmol) isobornyl acrylate and 0.068g (1.5%) 2,2- Azobisisobutyronitrile was added to 20 mL of dioxane, deoxygenated by nitrogen gas for 30 min, and reacted at 70°C for 24 h. After the reaction, the precipitation was repeated three times in petroleum ether to obtain a spare polymer. Dissolve 2 g of spare polymer in 10 mL of dioxane, add 0.353 g of propane sultone, and react at room temperature for 12 hours. After the reaction, the reaction solution is concentrated by rotary evaporation, precipitated in ether three times, and dried in vacuo Finally, an amphiphilic zwitterionic functional polymer with a sulfonation rate of 50% is obtained.

[0050] Step b) Preparation of the complex colloid solution: Diss...

PUM

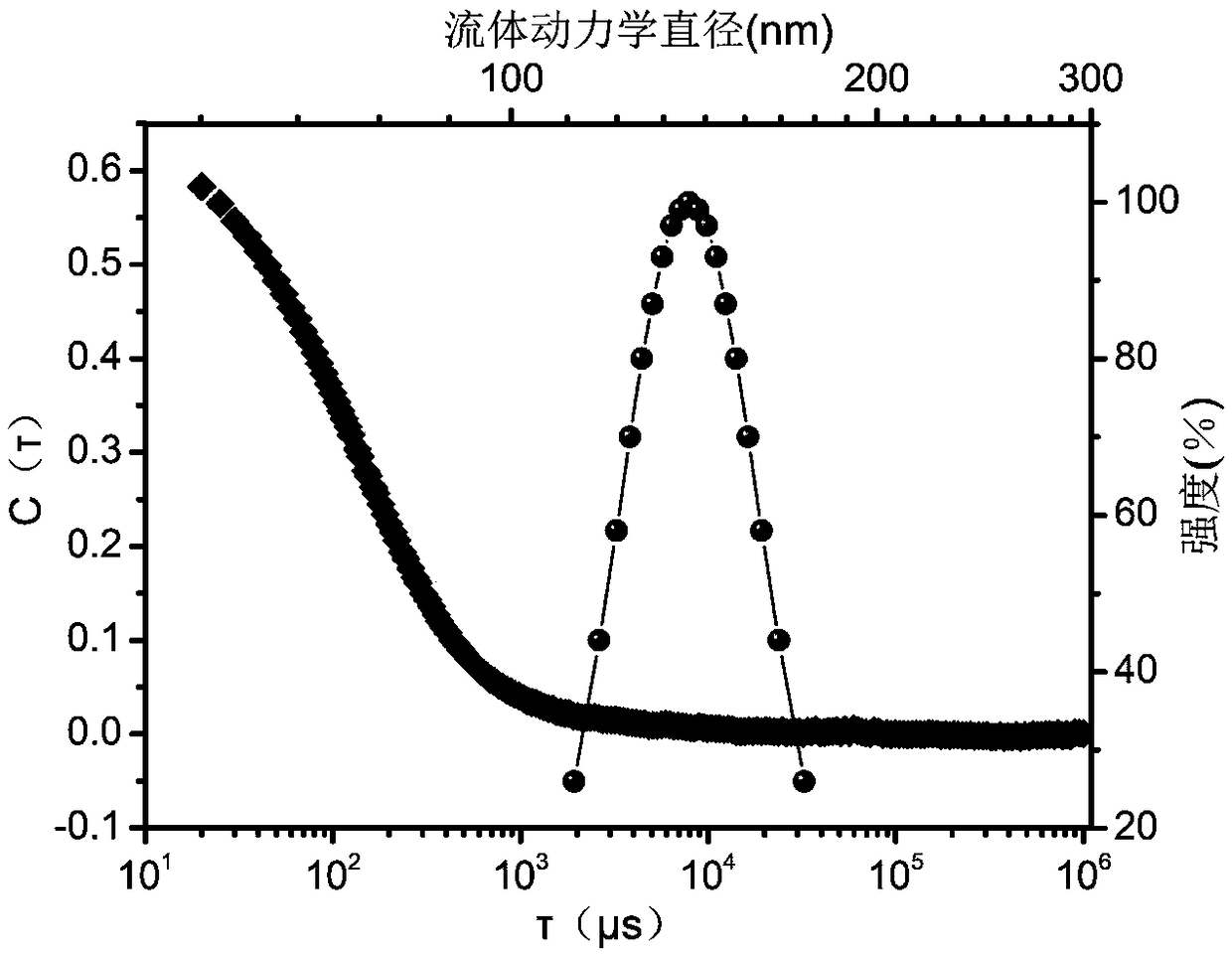

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap