Material conveying method of removal tower

A removal tower and removal technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of secondary recycling and environmental protection of unfavorable removers, large powder removal of removers, and removal of It can improve the secondary utilization rate, reduce environmental pollution and reduce the wear rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

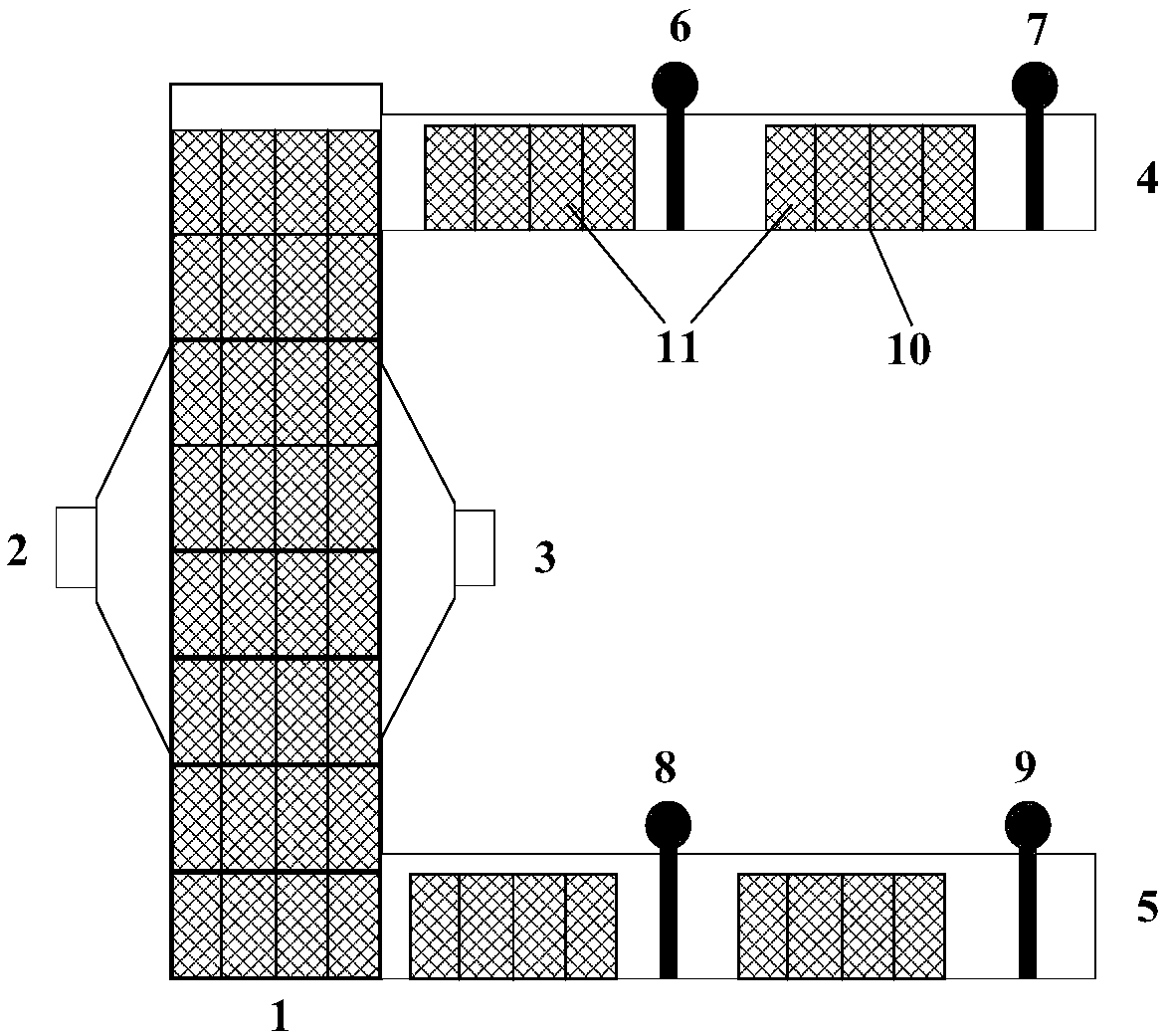

[0045] combine figure 1 , the present embodiment adopts the first type of removal unit cell 10 to carry out the removal treatment, the surface connecting the gas inlet 2 and the gas outlet 3 with the tower body is a steel plate, and the mesh diameter of the steel plate is 5mm; the gas inlet 2 and the gas outlet 3 are respectively arranged on both sides of the removal tower 1, and the gas flows in the horizontal direction in the removal tower 1. In this embodiment, the first type of removal unit cell 10 is provided with 3 vertical and 3 horizontal unit middle plates, the unit middle plate is a steel plate with mesh, and the mesh diameter is 8mm; a pair of side faces in the unit cell 10 are removed It is a steel plate with a mesh, the mesh diameter is 8mm, and the rest of the surface is an airtight sealing steel plate. The gas removal agent is active coke, which is cylindrical, with a diameter of 10mm and a height of 12mm. Gas inlet 2 SO 2 The content is 600mg / m 3 .

[0046...

Embodiment 2

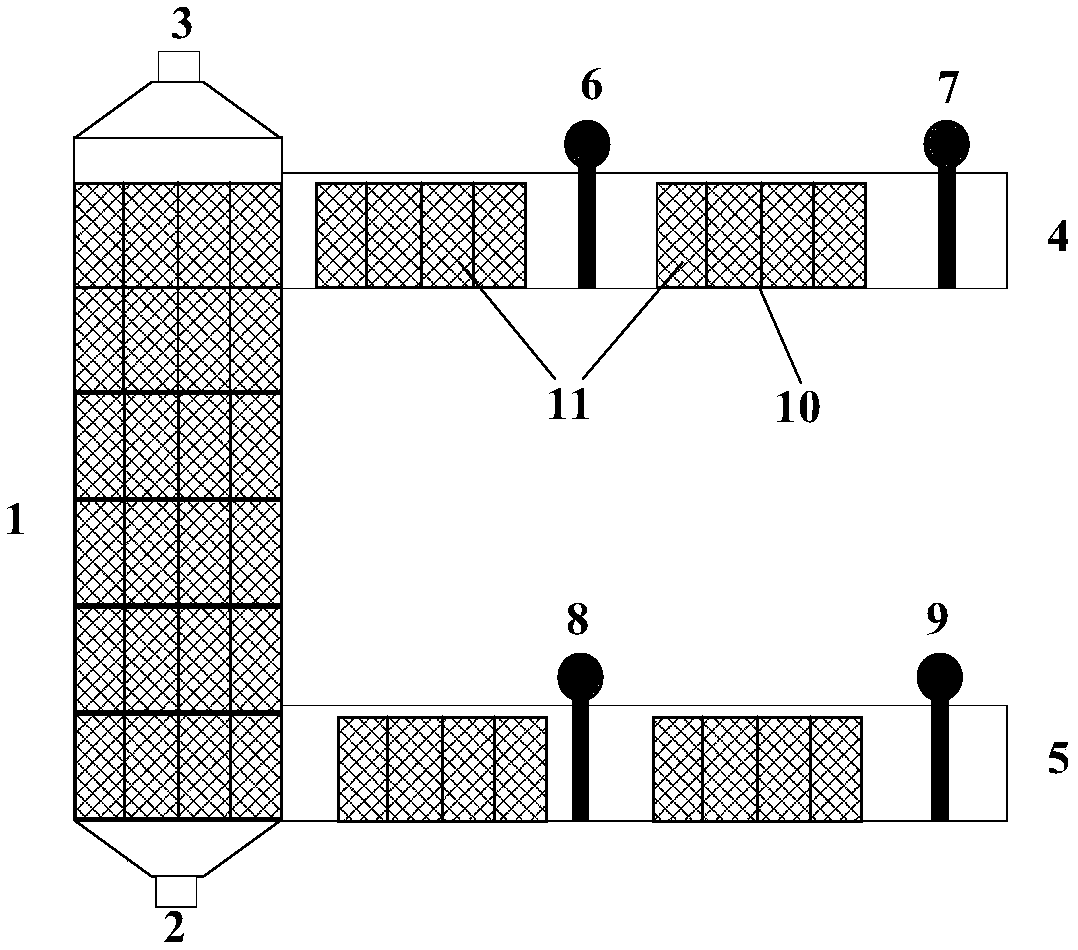

[0056] combine figure 2 , the present embodiment adopts the second type of removal unit cell 10 to carry out the removal treatment, the surface connected to the tower body by the gas inlet 2 and the gas outlet 3 is a steel plate, and the mesh diameter of the steel plate is 5mm; the gas inlet 2 and the gas outlet 3 are respectively arranged at the bottom and top of the removal tower 1, and the gas flows in the vertical direction in the removal tower 1. The second type of removal unit cell 10 adopted in this embodiment is provided with 3 vertical and 3 horizontal unit middle plates, the unit middle plate is a steel plate with mesh, and the mesh diameter is 8mm; remove the top surface and The side in the direction of the bottom is a steel plate with mesh, the mesh diameter is 8mm, and the side in the other direction is an airtight sealing steel plate. The gas removal agent is active coke, which is cylindrical, with a diameter of 10mm and a height of 14mm. Gas inlet 2 SO 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com